Determining power supply efficiency

Modern power supplies are characterised by claims of ever higher efficiencies, but can designers rely on datasheet specifications, asks Bernhard Erdl, PULS Power

Accurate power supply efficiency measurement is critical for design engineers. Efficiency specifications are provided by manufacturers, but how are the values determined? Can an end user make measurements and what would be involved in doing so?

More and more system designers are realising that the efficiency of a power supply has a direct influence on its reliability. It is essential – especially in the case of convection-cooled devices – to balance the required dimensions for the power supply against the reliability or end product lifetime. Without additional ventilation, heat can only be dissipated to a limited degree and the designer of a power supply must be very careful to achieve the lowest possible heat generation. Other essential system elements will also benefit from low power losses and minimal heat generation from the power supply.

Five recommendations

The following should be given highest priority when measuring efficiency. They have proved to be indispensable in practice.

Use precision meters. If possible, power analysers or accurate wattmeters;

Ensure proper cabling when setting up the measurement and that the correct voltage is being measured;

When taking AC measurements, always use an electronic AC source if available;

Avoid EMC interference from the device under test;

Consider temperature and time influences.

Efficiency is a figure that helps designers carry out a proper comparison of different power supplies. However, system designers and users of power supplies are even more interested in the heat which remains in the power supply, i.e. the power losses. Since these power losses cannot be electrically measured in a direct manner, one can only consider the difference between input and output power.

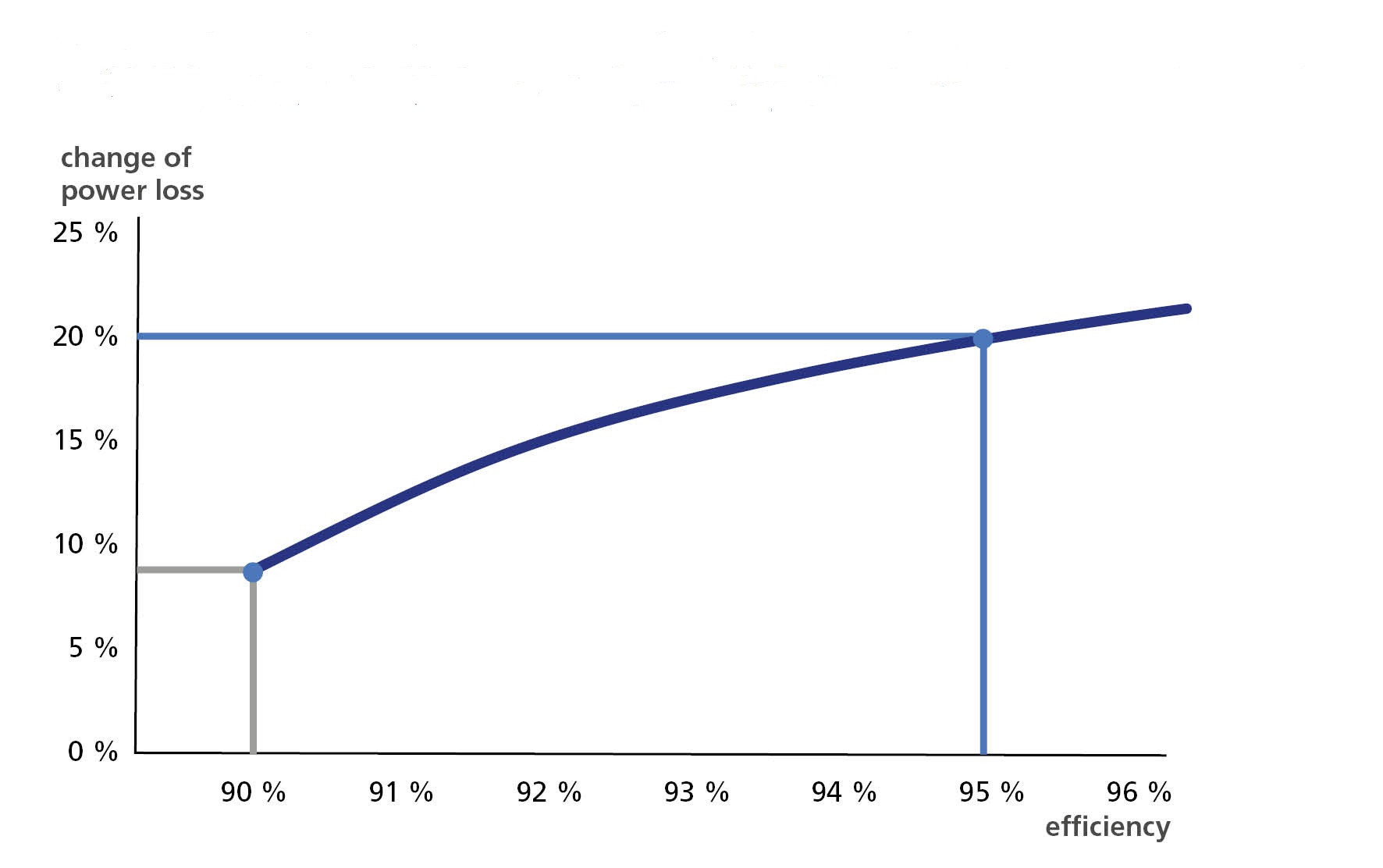

Currently most efficiency values lie at around 95%, which corresponds to a loss of 5%. However small measurement errors in the input and output power lead to large errors when calculating power loss. If there is a measurement error of just 0.5%, i.e. a total of 1%, the power loss calculation would be wrong by 20%. (See Figure 1)

Figure 1: The impact of a 1% measurement error in the change in no-load losses, with increasing efficiency

It is also important to keep in mind that seemingly small differences in efficiency mean a big difference in power losses. The values for modern power supplies lie between 92 and 95%. The user might have the impression that one or 2% difference will not be significant. This is a misconception; it is not the absolute value of efficiency but rather the difference from the ideal value of 100% that matters most.

As an example for comparable power supplies with 48V / 5A output, the PULS QS10 has an efficiency of 92.0% and the PULS CP10, introduced 10 years later, has an efficiency of 95.5%. At first glance, the difference does not seem to be a big improvement. However, the power losses of the CP10 have been reduced by 41% when compared to the QS10 model.

This means that at high efficiencies, even small increases produce a significant reduction in no-load losses. With increasing efficiencies, measurement accuracy keeps gaining in importance, as otherwise it would be impossible to determine no load losses properly.

Avoiding errors

The closer the developer gets to 100% efficiency, the harder it becomes to measure accurately. Absolute measurement precision is therefore essential to give an accurate statement about no-load losses in a power supply. Many errors could be avoided by good preparation and professional measurement.

The most common sources of error are, incorrect measurement principle due to unsuitable meters, inaccurate meters, faulty measurement set up and neglecting environmental conditions.

Selecting the tool of choice

There are a number of measuring instruments which are used to determine efficiency. However, the measurement tolerances and the capabilities of measuring instruments when measuring various signals (AC or DC) varies considerably.

Multimeters measuring the voltage and current of purely DC inputs and outputs. The voltage can be measured with high precision directly at the input and output of the power supply. Many multimeters also have built-in ability to measure current, but this can have an inaccuracy of 1% or more, the multimeter measuring range is limited to 10A. Instead, the current should be measured by high precision shunt resistors with 0.01% tolerance. However the non-synchronous detection of values can be problematic because it leads to errors if fluctuating conditions are present.

Data loggers are better for DC measurements. They consist of a single meter which is used several times by multiplexing. In the same measuring range, the errors cancel each other out and all values can be promptly recorded and evaluated quickly with a spreadsheet.

However, AC input power cannot be measured with multimeters or data loggers. It is a common mistake to assume that it is sufficient to measure the true RMS of the current and voltage and to multiply the two values to determine the input power. This calculation, however, determines the apparent power and not the real power which is crucial for the power losses. The measurement of AC input power, even with true RMS multimeters, gives incorrect measurements.

Watt meters are used for measuring AC signals and offer the correct principle. The instantaneous values of current and voltage are multiplied and a mean value is calculated from these products. This corresponds to the physical definition of performance. However, most simple wattmeters have a high measurement inaccuracy (around 1%). Frequently changing input or output currents (AC input, varying output load) causes additional measuring errors. Fluctuating values are thus difficult to interpret. Generally, only high-precision wattmeters should be used when measuring efficiency.

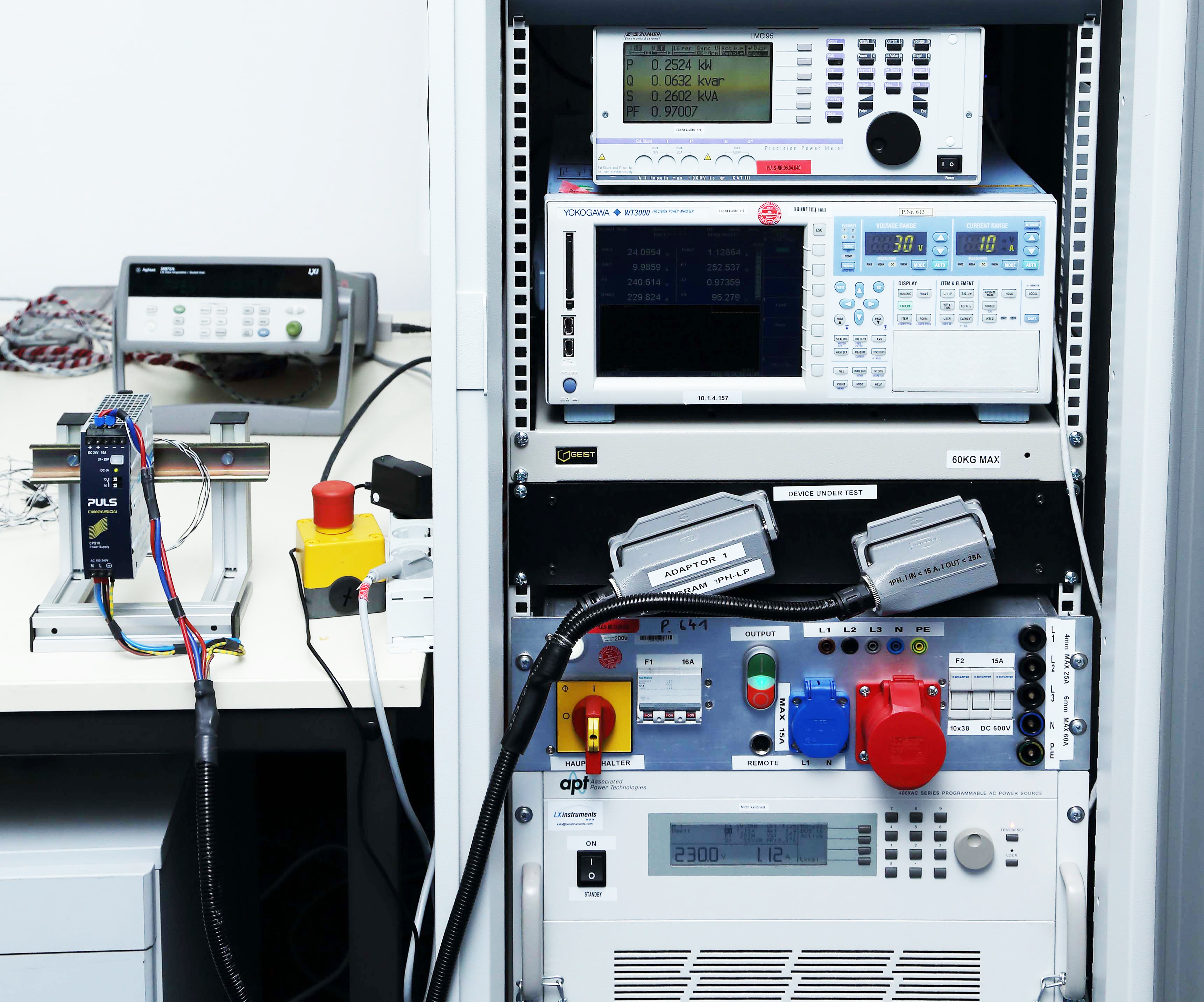

Power analysers to measure the efficiency of its power supplies have a high basic accuracy of 0.02%. Other benefits are measuring of active power, the simultaneous, and thus synchronous, measuring of input and output and the direct display of power losses and efficiency. A disadvantage is the high purchase price involved. Nevertheless, the power analyser is the tool of choice for accurate determination of efficiency (Figure 2).

Figure 2: The efficiency of PULS switch mode power supplies is measured by power analysers

Figure 2: The efficiency of PULS switch mode power supplies is measured by power analysers

A precise and expensive power analyser may however not provide accurate results if mistakes were made during the measurement setup.

All power losses that do not come from the device under test are not allowed to be included in the measurement. This is the main principle, when it comes to correct wiring in the measurement set up. Every cable and every contact resistance causes additional power losses that may distort the measurement results. A proper four-pole measurement (Kelvin measurement) must have separate cables for the measurement of current and voltage. (See Figure 3)

Voltage source

Simple DC voltage supplies are sufficient for switch mode power supplies with DC-input. For AC measurements, it is important to know that the internal resistance of the voltage source influences the measurement through the curve shape of the mains sine. In a 240W power supply without PFC, a difference of 0.4% was measured between the soft power from an isolating regulating transformer and the hard power from an electronic AC source. This gives the most reproducible values and is therefore preferable.

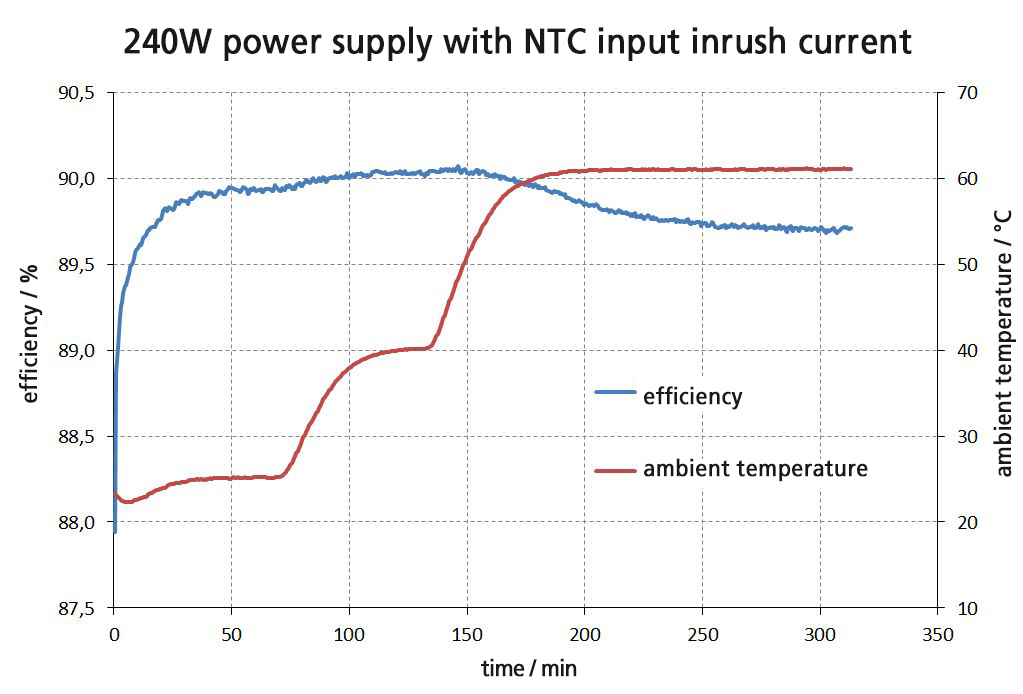

Figure 3: Due to the NTC, efficiency is highly dependent on time and temperature

Figure 3: Due to the NTC, efficiency is highly dependent on time and temperature

In addition to the power source, the load used must also be stable and reproducible. The loads from power resistors are problematic because they do not draw a constant current. Electronic loads represent a defined and reproducible load for the device under test and even fluctuating transition resistances do not alter the current.

Unshielded power supplies in the prototype stage can interfere with meters and/or can cause loads to fluctuate. Measurements should accept no signals with HF interference from meters. Additional filters, mostly inductors in the input lines, prevent these problems. Power losses should not be able to flow into the measurement. There should be no such problems when measuring clean, radio interference- suppressed power supplies.

Environmental considerations

Temperature plays a decisive role, because the power losses from a power supply are temperature-dependent. The temperature of the components in a power supply is a crucial factor. The component temperature is the sum of ambient temperature and self-heating.

The various components in the power supply react differently to temperature. In some essential elements an increase in temperature results in a reduction of power losses, and in other components it increase them. The negative temperature co-efficients (NTCs) used for limiting the input inrush current have a strong influence. Power supplies with such components have less power losses when running and in higher ambient temperatures (negative temperature coefficient), because at higher temperatures the increase of power loss is outweighed again by other essential elements. (See Figure 4)

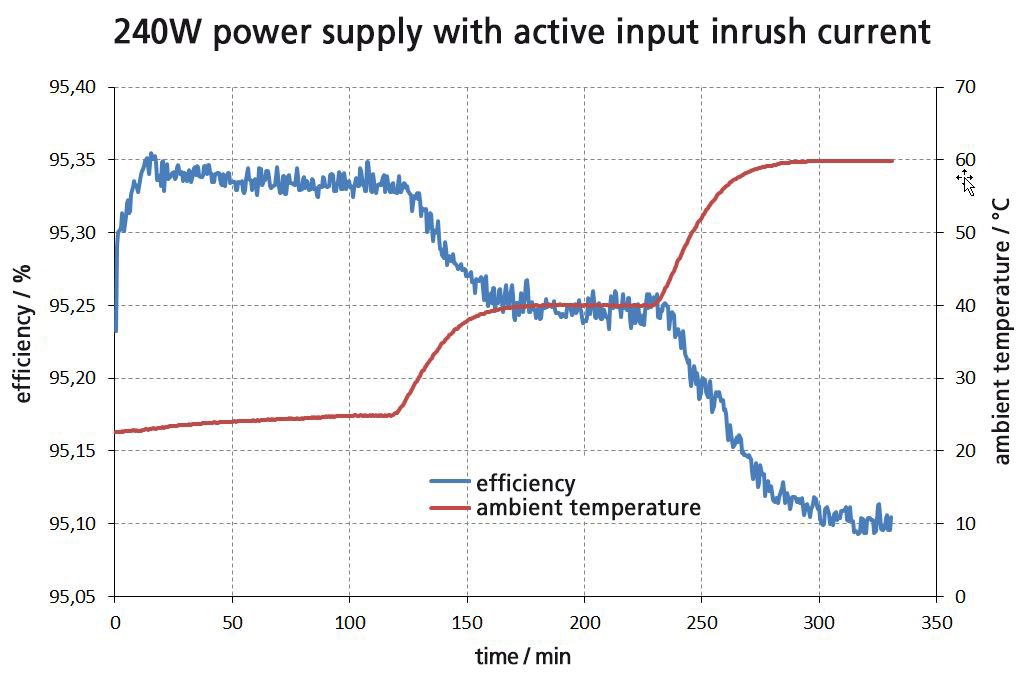

Figure 4: The active inrush current limiter without NTC gives an efficiency that is less time- and temperature-dependent

Figure 4: The active inrush current limiter without NTC gives an efficiency that is less time- and temperature-dependent

Devices with an active input inrush current limiter display a more stable temperature behaviour. Here there is only a small increase in power loss from temperature. (See Figure 5)

When taking any efficiency measurement, the running time and the ambient temperature should be documented so that the results remain traceable.

Since cooling is done by air, the air pressure has an influence on self-heating. PULS has calculated how much additional heat is generated by components at a higher altitude, i.e. by approximately +10°C at an altitude of 2,000m above sea level and approximately +20°C at 4,000m. Humidity plays only a very minor role and can be neglected.

Every component used in a power supply has tolerances and therefore not every device manufactured is the same. To find genuine errors, PULS measures power losses very closely, even during production although this is not quite as accurate as in the laboratory.

Users who want to know in more detail, can take their own measurements or find another manufacturer who provides full and accurate specifications. Even then, they might feel more reassured if they take one last measurement themselves.