Choosing appropriate DC/DC converters for use in industrial settings

Choosing DC/DC converters in industrial applications can be a considerable challenge, Mike Green, Technical Contributing Editor for TME explores.

This article originally appeared in the April'23 magazine issue of Electronic Specifier Design – see ES's Magazine Archives for more featured publications.

In modern industrial systems, the nature of loads has changed, especially in areas such as robotics where the loads are much more dynamic, changing from rest to full power in a matter of milliseconds. In other cases, as more control is being introduced to systems, the power requirements may be somewhere less than the full load for extended periods of time – with brief overload (peak power) occurring on a regular basis.

This can cause challenges with the choice of power system, as designers need a solution that is rugged enough to withstand operation in this type of environment while operating as efficiently as possible at all load conditions – especially partial loads. This is increasingly important in the face of skyrocketing utility bills, as well as the need for companies to curb their carbon footprint.

In this technical article, we will look at the many considerations for creating a power solution for industrial applications, whether that is to design from scratch, or select one of the many high-performance solutions available on the market.

Every system needs some form of power, so every design requires engineers to ensure that an appropriate power solution is available. Inevitably, this tends to happen later in the design cycle once the system configuration and its power needs (voltages, rails, consumption figures) are known and reasonably stable.

Make or buy?

The first consideration of every design is the ‘make vs buy’ decision. There is a myriad of factors that will play into this decision including the skill sets of the designers, the complexity of the required solution, the cost sensitivity of the project, and the regulatory requirements, etc.

There are many elegant solutions available on the market, along with detailed application notes and experienced support teams to allow designers to create their own power solution – from a fully discrete design, or a more modular approach with a controller, MOSFETs and a few passive components. The benefits of this approach include having a solution that exactly matches the requirements of the design and often (although not always) a lower-cost solution. On the downside, the designer must design and debug the circuit, as well as managing EMC compliance and any safety approvals. From a supply chain perspective, there are multiple components to purchase and inventory, as well as multiple suppliers to manage.

With the huge number of pre-built modules available on the market today, it is now relatively easy to configure almost any combination required from off-the-shelf devices. Increasingly, designers are turning to these pre-built solutions as power becomes more complex and demands increase. When taking the modular approach, designers can have a working prototype in a very short time and, if they have selected the correct devices, they know that safety and EMC requirements have already been met, and suchlike.

Often a modular solution will be smaller and offer better performance (because of years of development work on the vendor’s side) than a discrete design. While the main reason to ‘go discrete’ is the lower cost, this is often not the case in practice, especially in industrial applications where the manufacturing volumes are lower. Clearly, there are supply chain cost savings with a far smaller bill-of-materials (BoM) and reduced supplier base.

Other considerations for industrial power

Efficiency is on every agenda these days. Requirements are becoming more stringent, because of needing to manage operating costs in the face of rapidly rising energy prices and minimise environmental impact.

In the past, power module manufacturers often quoted a single figure for efficiency and, of course, this was always the best possible number. This would often be at (or close to) full load. However, in real-world applications, very few power systems operate at full load all (or even most) of the time. As a result, these headline efficiency figures are rarely achieved.

Apart from the costs involved in wasting energy, efficiency can have a material impact on the size and weight of a design. In a less efficient solution, more waste heat is generated, and this has to be dissipated, requiring the use of thermal management techniques (including fans and/or heatsinks). All of this adds to the overall cost and size of any solution.

In recent years, there has been a shift to considering the efficiency at all power levels, especially at lower levels, including the power consumed when in ‘standby.’ When specifying a power solution, designers must fully understand the power profile of their application (the time that will be spent at different power levels) and review efficiency curves to help them with selection.

The industrial environment is often challenging for electronic hardware, especially where large switchgear is deployed, such as that associated with motor drives or welding. These can present large voltage spikes, either conducted through the power cables, or radiated through the air. They can prove destructive for sensitive electronics, and so appropriate protection within the power solution will be required. Some power modules that are specifically intended for use in an industrial environment may have built-in protection circuitry, while for others suitable components can be added externally.

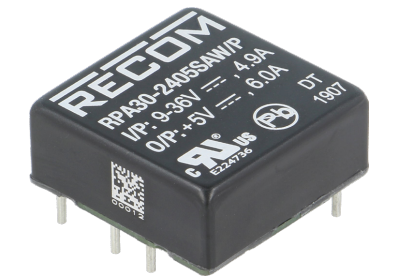

Figure 1. RECOM’s RPA30-AW DC/DC converters

Depending upon the proximity to sources of radiated noise, either a module that is qualified to a higher-level EMI will be needed or the system may need to be housed in a shielded metal enclosure. This further reinforces the need for efficient operation, to reduce heat build-up in an enclosed space.

Further challenges associated with industrial use include shock and vibration. These are usually of most concern if the power module is being mounted on a piece of machinery that is rotating or moving, such as a motor or robotic arm. Exposure to extreme temperatures may also need to be factored in. Not only should a module that has been tested in this environment be selected, but consideration also as to how and where it is mounted will be required, including the possibility of additional mechanical support.

Assuring reliability

Reliability is, of course, paramount in an industrial context – as any unplanned downtime will have financial implications for any business. Ensuring reliability starts with selecting a power module that is suited to deployment in an industrial environment, with transient protection and EMI resilience. Also, the mean time between failure (MTBF) must be well aligned with the intended lifetime of the system. Ensuring suitable design margins in a correct tolerance design is also important, to ensure that the power module is never over-stressed.

Inevitably, even with the most reliable devices, some failures will occur. One way of minimising downtime is to include a hot-swap capability into the system so that a failed module can be quickly extracted as part of a sub-assembly (often without the need for tools) and rapidly replaced. This can ensure operation ceases for no more than a few minutes.

In applications where absolutely no downtime is acceptable, then redundancy will be needed. Here, additional power modules will be designed into the system and configured so that if one module fails then the remaining modules will continue to power the load. As the load is normally shared by more power modules than necessary, during normal operation, they will never reach full load. That means high efficiency at less than full load is an important requirement in redundant systems. While redundancy is a useful technique for ensuring reliability, the lack of space in many modern systems often precludes this as an option.

Example industrial DC/DC converters

Thanks to its close relationship with RECOM, TME has an expansive portfolio of DC/DC converters for industrial implementations. These cover a wide power range from 20W up to 200W. The RPA30-AW series are high power density 30W units supplied in an industry-standard 1x1" case size. Despite their small size, these DC/DC converters are fully specified with output currents up to 7.5A, no minimum load, 1600VDC isolation, tight regulation, and low ripple/noise figures.

The RPA30-AW units offer up to 89% efficiency with a very flat efficiency curve that still delivers in excess of 80% efficiency even when at just 20% load. This is helped, in part, by the low quiescent current exhibited, which is less than 55mA. The outputs are also fully protected against over-temperature, short circuits, over-current and over-voltage, and the single output version offers a ±10% trim range. A heatsink option is available to extend the operating temperature range up to 56°C without derating. These converters are UL and EN50155 certified and are highly effective in industrial applications where board space is at a premium.