Can you hear the digital difference?

Wireless charging solutions for hearing aids have gained in sophistication. Steve Knoth, Linear Technology (part of Analog Devices), charts the changes

Hearing aid technology has continuously improved over the last 20 to 30 years. For example, compared to the relatively inexpensive analogue circuit type of hearing aid, a more sophisticated digital hearing aid can be programmed to amplify some frequencies more than others. A digital hearing aid can be adjusted to the wearer's individual hearing needs, tuned to certain environments, and can also be programmed to focus on sounds coming from a specific direction. These features make hearing aids more sophisticated than simple sound amplification devices.

The two most popular models are the behind the ear (BTE) style hearing aid, and the receiver in the canal and receiver in the ear (RIC/RITE) type hearing aid.

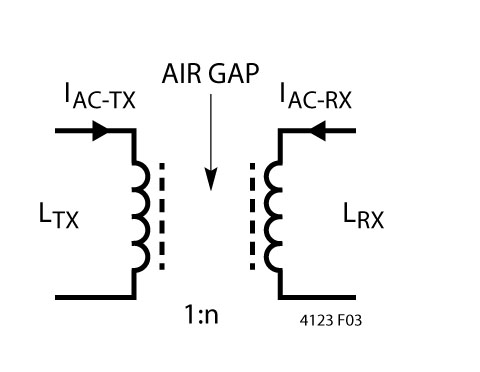

Figure 1: Wireless power transfer (WPT) system

Figure 1: Wireless power transfer (WPT) system

Both types are commonly powered using a non-rechargeable, small zinc-air (Zn-air) primary battery (0.9 to 1.25V). This battery chemistry has high volumetric energy density, resulting in a long run time and a small form factor. However, Zn-Air batteries cannot be recharged, forcing the user to change the battery every seven to 10 days.

Battery options

Frequent changes of a very small battery in a very small enclosure can be problematic and 'fiddly'. In contrast, a Li-ion battery offers reasonable runtime, and can be recharged, and therefore does not need to be replaced frequently. Â Currently, there is no single IC battery charging solution available. Typical hearing aid electronics run directly from a single-cell Zn-air battery, and the Li-ion output voltage is roughly three times higher than this. Therefore, a Li-ion based solution requires both a battery charger and a step-down regulator to deliver the correct voltage to power the hearing aid ASIC. This multiple-IC approach is relatively large and generates switching noise/EMI which can be problematic for the sensitive audio circuitry.

A rechargeable NiMH powered battery offers the best of both worlds. The NiMH cell has nearly identical voltage output to the Zn-air cells (therefore no additional step-down regulator is necessary), is rechargeable and available in form factors that are the same as those of the standard Zn-air battery, allowing for a small overall hearing aid unit.

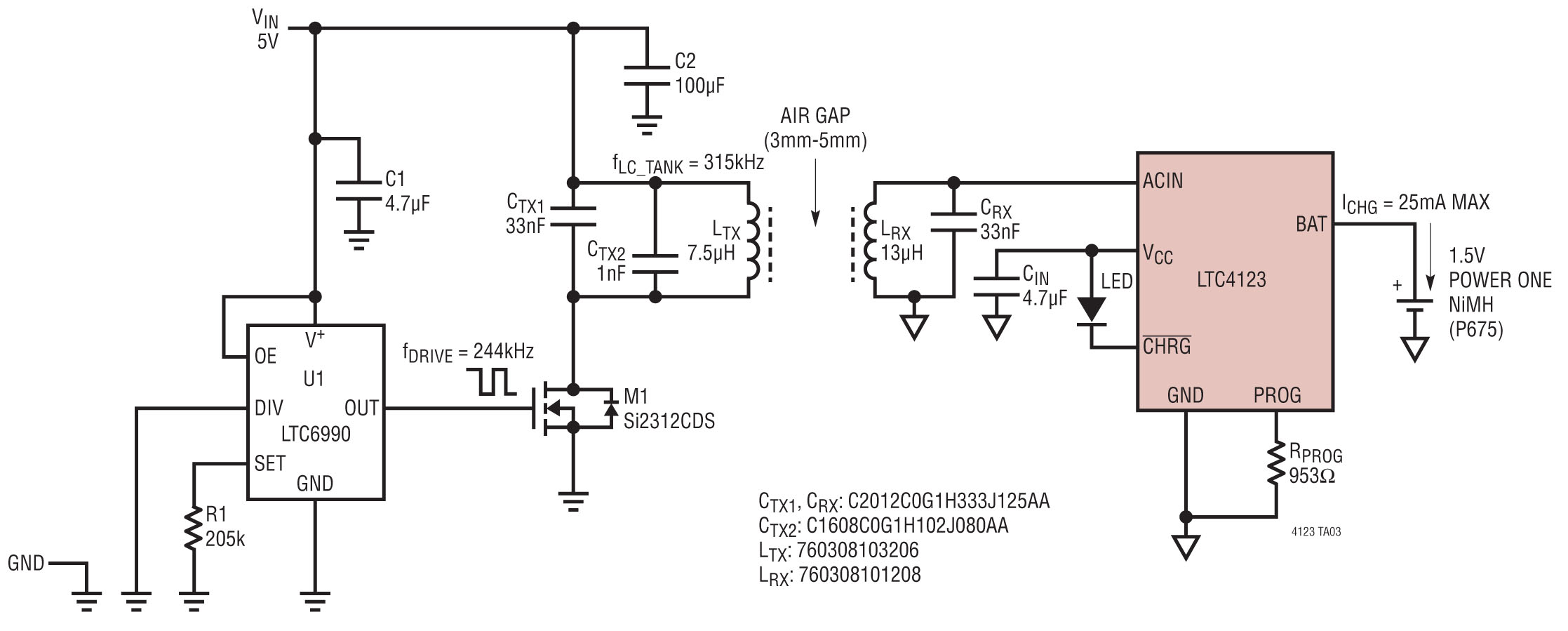

Figure 2: Typical schematic of the LTC4123

Figure 2: Typical schematic of the LTC4123

Why is a wireless charger needed? Recharging a battery removes the need for frequently swapping out battery cells, a benefit for a wearer who might have difficult with manual dexterity, and is also more convenient for those that are still good with their hands. Wireless charging is just that: charging without wires; no connectors required. Combining a wireless charging method with a NiMH battery cell can provide a robust and convenient charging solution. It allows the hearing aid to be sealed and waterproof, reducing the need to open the unit, while also protecting it, increasing reliability and longevity.

Wireless power transfer

An inductive wireless power transfer (WPT) system, shown in Figure 1, consists of transmitter electronics, a transmit coil, a receive coil, and receiver electronics. Received power depends on transmit power, coupling between the transmit (Tx) coil and receive (Rx) coils (distance, alignment, physical properties, ferrites), nearby unrelated metal, as well as component tolerances. In a WPT system, power is transmitted using an alternating magnetic field. An AC current in the transmit coil generates a magnetic field. When the receive coil is placed in this field, an AC current is induced in the receive coil. The AC current induced at the receive coil is a function of the applied AC current at the transmitter and the coupling between the Tx and Rx coils. The power transmission range across the air gap can be improved using resonance by connecting a resonant capacitor to the receiver coil to create an LC (inductor and capacitor) tank tuned to the same frequency as the transmit coil AC current frequency.

Historically, to build a WPT charging system was complex, requiring a battery charger, switching buck regulator and WPT circuitry. It could also be large and difficult to design.

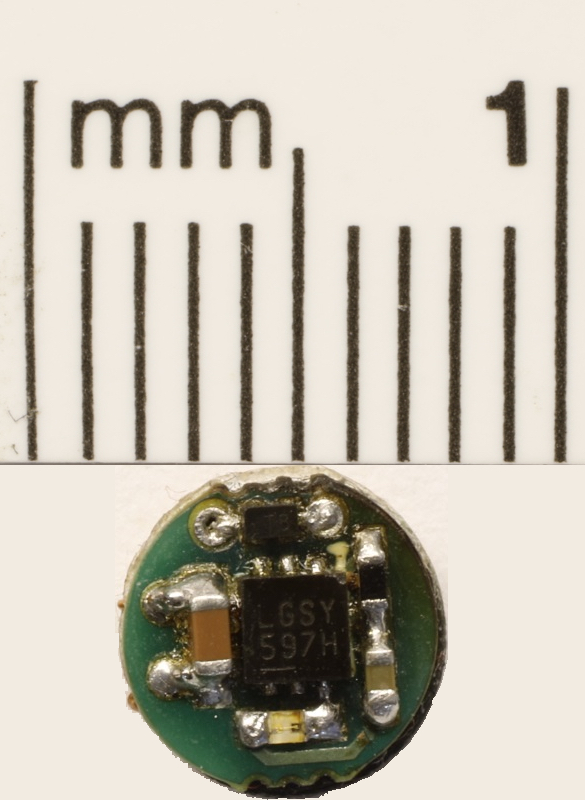

Figure 3: LTC412's charger/receiver circuitry (6mm diameter)

A wireless power receiver and charger solves these issues. Wireless charging removes the need for frequently swapping of the battery, and allows for a sealed, waterproof, more robust hearing aid. The small Rx and WPT circuitry are integrated in one IC.

Another benefit is temperature compensated charging, which allows for safe charging of the NiMH battery. With Zn-air battery detection, the hearing aid may function with either NiMH or Zn-air batteries. A rechargeable NiMH cell is for normal use, but in an emergency when the user has forgotten to charge the NiMH cell, a non-rechargeable Zn-Air battery cell can be safely inserted.

To address these specific needs, Linear Technology (now part of Analog Devices) has introduced the LTC4123, a low power, wireless charger for hearing aids which ensures that it does not charge - and thereby damage - it.

Integration and interoperability

The 30mW wireless receiver has a constant current/constant voltage linear charger for NiMH batteries, such as Varta's Power One ACCU Plus series. An external resonant LC tank connected to the LTC4123 enables the IC to receive power wirelessly from an alternating magnetic field generated by a transmit coil. Integrated power management circuitry converts the coupled AC current into the DC current required to charge the battery. As a result, wireless charging allows for a sealed product and eliminates the need to constantly replace Zn-air primary batteries.

For products that demand the flexibility of operating from multiple battery chemistries, the Zn-Air detection feature allows the same application circuit to work interchangeably with both rechargeable NiMH batteries and primary Zn-air batteries. Both battery types can directly power a hearing aid ASIC without the need for additional voltage conversion. By contrast, a 3.7V Li-ion battery requires a step-down regulator in addition to wireless battery charging functionality to power the ASIC.

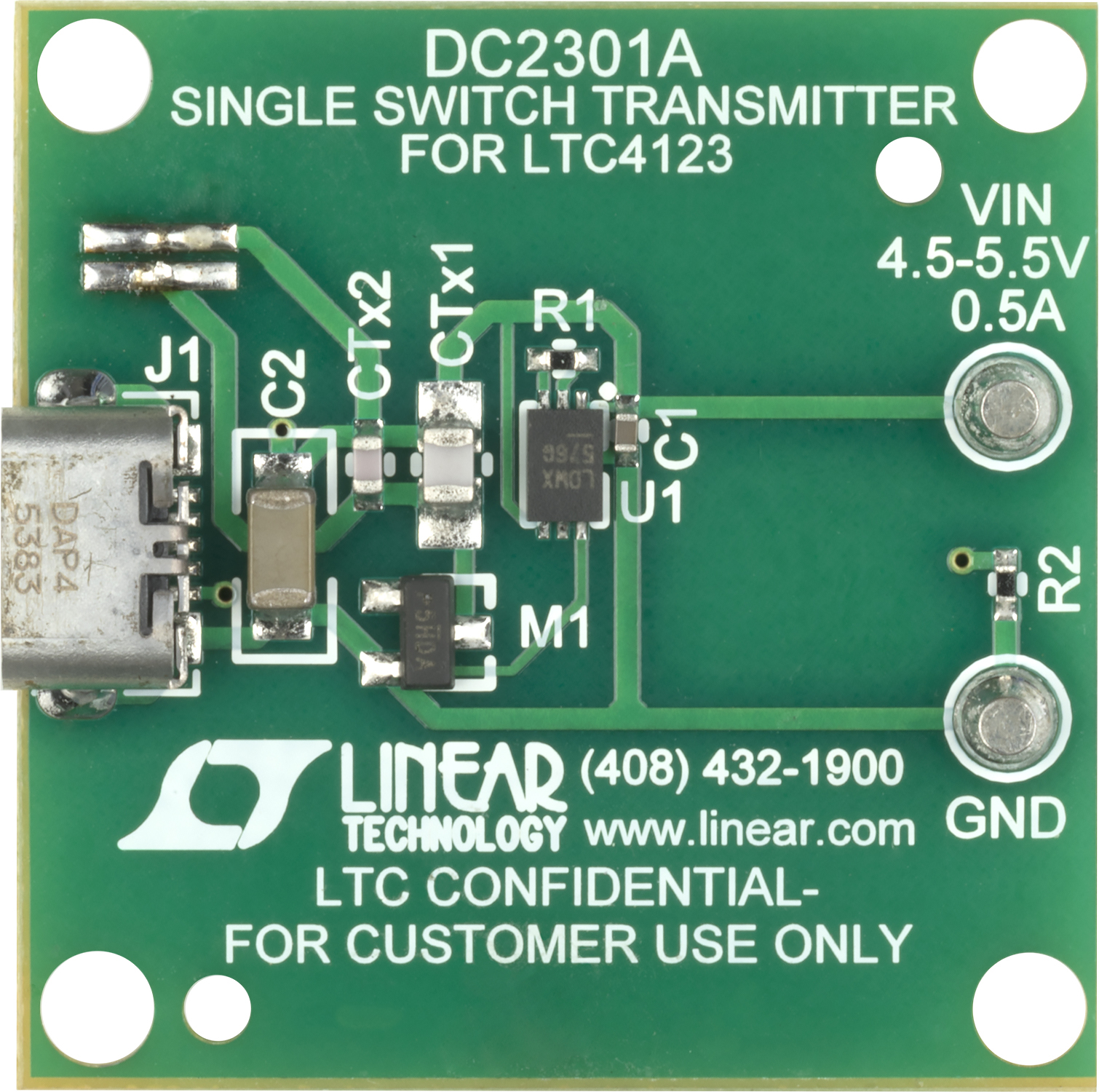

Figures 4 (above) and 5 (below): Front and back of transmitter demo board showing transmit circuitry and transmit coil

Figures 4 (above) and 5 (below): Front and back of transmitter demo board showing transmit circuitry and transmit coil

The LTC4123 rectifies AC power from the Rx coil and can also accept a 2.2 to 5.0V input to power a full-featured constant current/constant voltage battery charger. Features of the charger include programmable charge current up to 25mA, a temperature compensated single-cell 1.5V battery charge voltage with ±1% accuracy, charge status indication and an on-board safety charge termination timer. The temperature-compensated charge voltage protects the NiMH battery and prevents overcharging. Another feature of a wireless power receiver and charger is reverse polarity detection, which stops charging in the event that batteries are inserted backwards. Using hot/cold detection can pause charging if the battery temperature goes to extremes.

The LTC4123 is housed in a highly compact, low profile (0.75mm) six-pin 2.0 x 2.0mm DFN package and is guaranteed for operation from -20 to +85°C in the E grade version.

An inductive wireless power system consists of transmitter electronics, transmit coil, receiver electronics and a receive coil. The LTC4123 forms the basis for the receiver electronics in such a system. The receive coil can be integrated into the receiver electronics PCB. An external resonant LC tank connected to the ACIN pin allows the device to receive power wirelessly from an alternating magnetic field generated by a transmit coil. An LTC6990 TimerBlox voltage controlled silicon oscillator can be used as a transmitter (see Figure 2 for a typical application schematic).

Architecture advantages

Compared to a Li-ion and step down regulator-based, multi-chip approach, the LTC4123 has architecture advantages. The first is that single-cell NiMH rechargeable batteries are a drop-in replacement for the standard hearing aid application Zinc-Air (Zn-Air) primary cells. NiMH may not provide as much runtime as a Li-ion solution for a given battery size, however its runtime is adequate for the application.

Another benefit is that there is no need for an additional step-down voltage regulation stage. This reduces size, complexity and cost without concern for EMI/EMC switching frequency noise interfering with the audio quality.

Finally, it is a simple one-chip wireless charging solution for NiMH battery chemistries.

The LTC4123-based rechargeable NiMH powered charger offers hearing aid designers differentiating features and ease of implementation. The NiMH cell has nearly identical voltage output to the Zn-air cells, is rechargeable and has form factors that are virtually the same as those of the standard Zn-air battery.

A features set that adds wireless rechargeability and protection features to a hearing aid or other wearable devices with very little change to the system will appeal to designers and wearers alike. Now, offering both convenience and comfort, manual dexterity is not a pre-requisite for changing a hearing aid battery.