ASIC design improves transducer performance

An ASIC with on-chip Hall sensing elements improves the offset and offset drift compared to former circuits improves the performance of closed-loop current transducers. Fabrice Salvi, LEM, explains.

This ASIC is used in the LF xx10 current transducers series to increase accuracy, says the company.

The ASIC has 5,000 gates for digital block, and new features, namely a degauss sequence at start-up, over-current detection with a choice of over-range thresholds and programmability for end-users.

Hall cells are used in the ASIC as the sensing element to the magnetic field density. This construction has the advantages of isolation from the measured current and a wide frequency range including DC. The Hall cells are made using a standard 0.35µm CMOS process and so do not add cost to the ASIC.

The role of Hall sensors

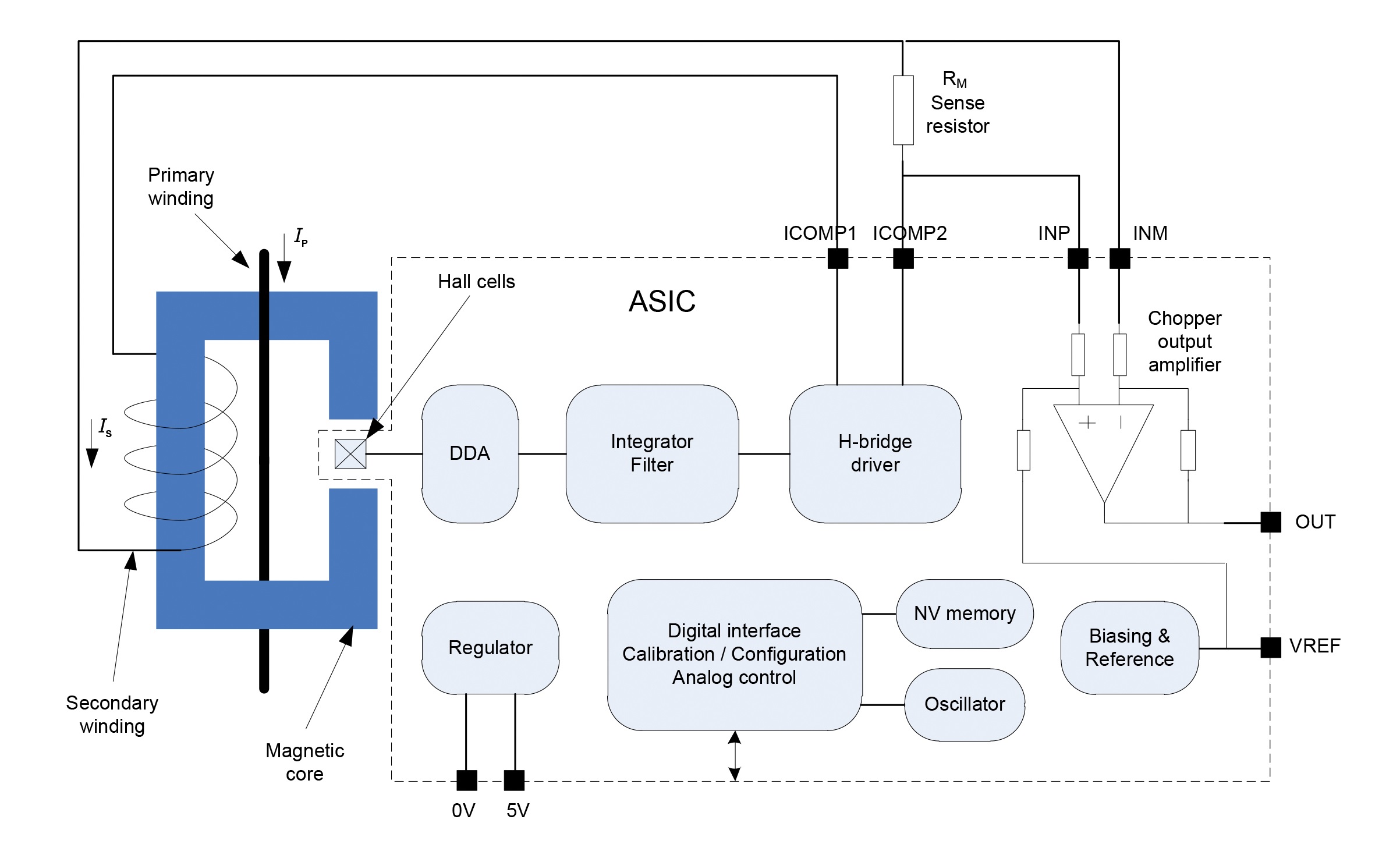

For DC and low frequencies (up to a few kHz), the magnetic flux density is sensed by the Hall sensors and a current (Is) is driven through the secondary winding and a measurement resistor (RM) nulls the flux in a closed loop arrangement. For higher frequencies, the transducer works as a passive current transformer and current cancels the flux from IP by the transformer effect. IS can be the output for current output transducers or converted to a voltage output with RM, followed by a voltage amplifier, for voltage output transducers. (Note: in Figure 1, the amplifier is not shown).

At frequencies above a few kHz, the secondary current comes directly from the transformer effect. It enables a fast step response that is only limited by the parasitic elements of the coil (resonance frequency) and the voltage amplifier bandwidth. Moreover, noise from Hall cells only contributes to the output noise at frequencies below the transformer effect while keeping a wide frequency range for the signal.

To overcome the offset and 1/f noise of the Hall cells, output is modulated to a high frequency (1MHz) by biasing the Hall cells successively in two orthogonal directions and then demodulated after amplification.

Component count

The ASIC minimises the number of electronic components needed to build a voltage output closed loop transducer: only three ceramic capacitors and one sensing resistor. For a current output transducer, the sensing resistor is removed and placed at the end-user side.

Figure 2 (above) shows the PCB schematic of a voltage output closed loop transducer. If the driver output voltage is not high enough (5V maximum) and/or the output current is too low (150mA maximum), a ±15V external driver can overcome these limitations. It is mainly used in case of high current measurements (higher than 500A) where the secondary coil current can exceed 1A. This is the case with the LF xx10 closed loop Hall effect current transducers.

Eight Hall cells improve the poor signal-to-noise ratio of the sensing element by a factor of . The signal increases by a factor of eight, whereas the noise increases only by a factor of.

Spinning at 1MHz eliminates at first order the Hall cell offset and 1/f noise. A differential difference amplifier is used to amplify the output of the Hall cells modulated to the spinning frequency, before the demodulator/integratorblock that is built in a single stage, using switched capacitor architecture. The integrator is the main contributor of the DC open-loop gain.

A class-AB driver (H-bridge driver) is used to provide the secondary current up to 150mA with a smooth zero-crossing behaviour. Its architecture is based on an H-bridge so that the full swing can go up to ±5V, less the voltage drops on the MOS switches (resistance around 5Ω).

To stabilise the closed-loop, a pole-zero compensator is added in the loop. A chopper stabilised amplifier with a fixed gain of four is used to give a low-impedance output after the current-voltage conversion by the sensing resistor RM. Offset has a standard deviation of 100µV.

ASIC programming can be done at LEM and/or the end-user with fuses. A standard UART bus interface is used to communicate with the chip in order to find the optimum configuration and then store it by blowing associated fuses.

Next-generation ASIC

One enhancement to this ASIC is the H-bridge (full swing ±5V) to drive the secondary coil. The previous ASIC was only able to drive ±2.1V. The drive output current for secondary coil has also increased from 40 to 150mA.

The ability to configure with a one-wire digital interface was not possible with the previous ASIC. Also not available in the earlier ASIC, this version has a current detection threshold in the range IPN to 5*IPN with a 0.25*IPN step.

The reference voltage output can be 0.5, 1.65 or 2.5V, and reference voltage input range can be from 0.5 to 2.75V. The previous ASIC had only a 2.5V reference output with ±25mV offset and an allowed reference voltage input range from 1.9 to 2.7V.

Integrator time constant and zero-compensation frequency value are programmed with the fuse bank, rather than by selecting the value with an external capacitor and resistor, as the previous ASIC.

The current output offset is always lower than 30µT with a temperature drift lower than 0.3 µT/deg. For a voltage output transducer, the 0.1mV offset of the out-of-the-loop amplifier contributes to the total offset. This offset is four times less than in the previous ASIC.

The Hall cell offset is only a few µT, due to a proprietary topology. It fragments the Hall device into multiple Hall blocks, distributed over the silicon area. The result is easy to interconnect to improve the effectiveness of the spinning technology.

The fragmentation allows splitting the offset of the Hall cell in small levels more effectively cancelled by the spinning technique.

The overall secondary current offset is trimmed by the silicon foundry and stored in a fuse bank. The offset of the output amplifier does not need trimming.

The ASIC is packaged in a thin 4x4mm QFN. It is qualified to AEC Q100 visual inspection, ESD, Latch up, temperature cycling, ageing 1,000 hours at 125°C with 85% relative humidity.

The closed loop current transducers, using this ASIC, cover models for 200, 300, 500, 1,000 and 2,000A nominal, to serve high-performance markets.

PCIM 2015: Hall 9 - 2014