Applying ASIC technology to electric vehicle battery management

There is a strong case for using ASIC technology in the management of battery power packs in EVs, proposes Swindon Silicon Systems

Electric-only vehicles as well as self-charging and plug-in hybrids currently play a modest role in new car sales. The automotive industry is slowly developing electric vehicle (EV) platforms that meet customer expectations as well as the environmental requirements of the governments of many countries.

Future deadlines for reducing or eliminating new diesel and petrol vehicle sales are already in place and the only alternative currently available is the EV. Although the majority of electric-only models are purchased as a second car, the major car manufacturers have begun to introduce vehicles with a more practical range which will see the adoption of EVs as the primary vehicle increase considerably.

Figure 1: The BMS is at the heart of the EV

Figure 1: The BMS is at the heart of the EV

Much of the range advancement is due to developments in battery technology where the size and weight no longer determine power output. In electric and hybrid vehicles, power is derived from a multi-cell power pack based, in most cases, on lithium ion or nickel-metal hydride technology. These power packs need to be monitored and managed to provide the vehicle’s central management system with a continuous flow of status information relating to the battery pack’s condition across a variety of parameters. A battery management system provides this information to the vehicle’s central control system.

Measurement

EV power packs are rechargeable which increases complexity. For example, EV drivers need to see a “fuel” gauge to know how much further the vehicle can travel before recharging. Unlike measuring the position of a float in a conventional fuel tank, determining the state of charge of a battery pack is not an easy task. Traditional lead acid batteries measure the voltage on their terminals but EV power packs give a fairly constant voltage output throughout the majority of their charge cycle. Other techniques measure the current flow over time to gauge how much energy has gone into the power pack or how much has been taken out.

In addition to state of charge calculations, it is also important to determine state of health. For example, any battery management system needs to ensure that the power packs do not overheat or are overcharged, which can be a fire hazard. A correctly designed battery management system will not only monitor and communicate the status of the power pack but also provide the optimum charging conditions and could even extend the life of each cell.

Many OEMs require each individual cell of the battery pack to be constantly monitored to give an accurate picture of the pack’s lifetime history. However, in the cost-conscious automotive sector, this is not always the case so the battery management system will monitor cell groups rather than each cell.

Electronic device manufacturers have begun to offer a variety of battery management solutions, to manage EV battery power packs, some based on standard components, but there is case to be made for a single chip approach using the mixed signal ASIC technology developed at Swindon Silicon Systems.

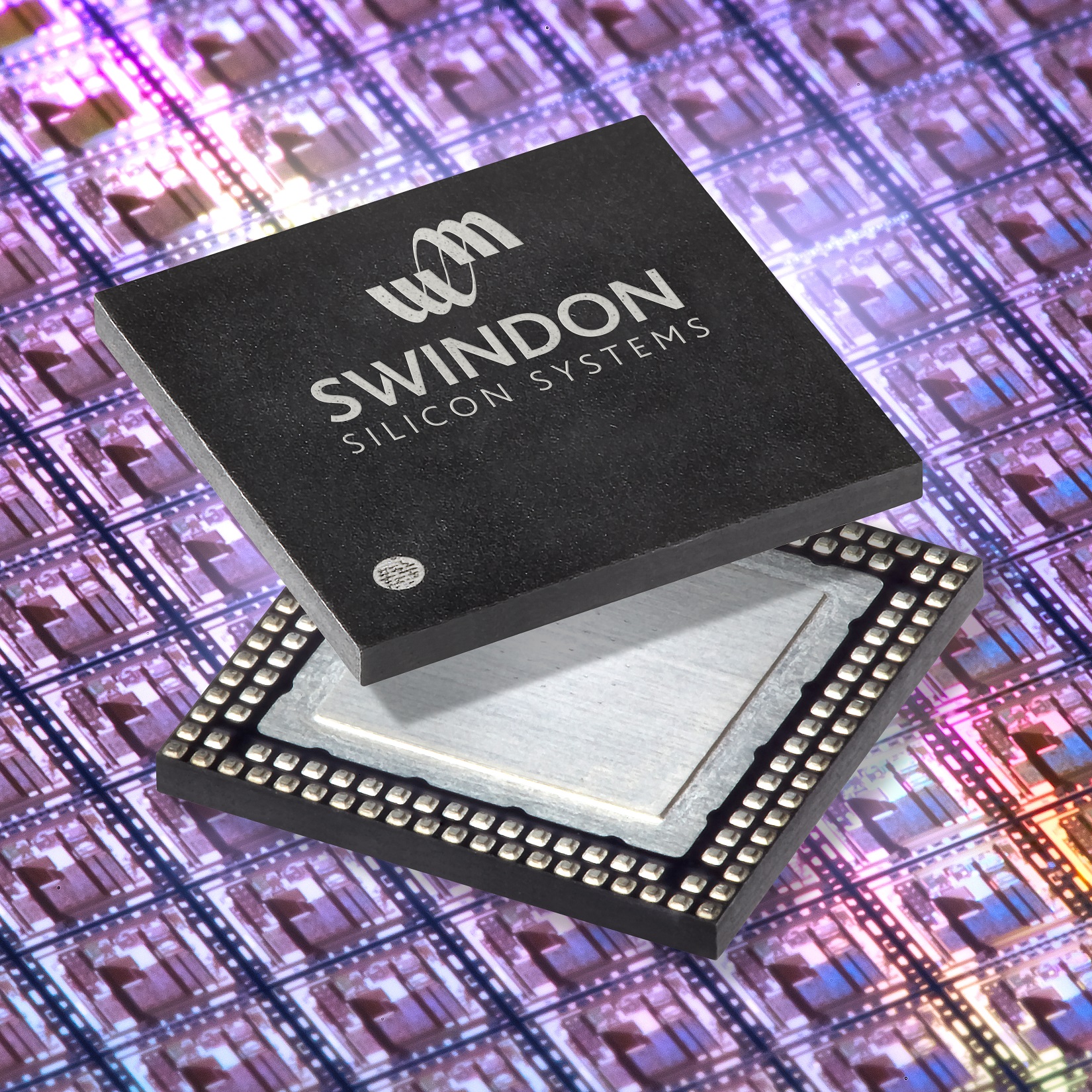

Figure 3: Choosing an ASIC protects against product obsolescence

Battery management systems (BMS) incorporate many functions such as a cell voltage monitor, temperature monitor, pressure monitor, signal conditioning, the “fuel gauge” and wired or wireless communications. These vary in complexity depending on the requirements of the OEM. A simple system will provide basic analogue information to a microcontroller, while a more integrated, standalone model will include all the functions necessary to constantly update the vehicle’s central management computer with the battery pack’s status.

A single chip solution

BMS sensing and measurement, on-board processing, software as well as different wireless communications standards can be included in a tiny single chip device. An ASIC offers customers a high degree of flexibility when it comes to selecting how the device will communicate. All of the leading communications protocols including 2.4GHz proprietary, Bluetooth Low Energy (BLE), power line communications (PLC) and, if the applications suits, near field communication (NFC) can be included in a tiny, single chip device.

There are other reasons to commission an ASIC for this type of application, for example size, performance, cost and reliability and an assurance against product obsolescence. An ASIC will reduce a user’s inventory and bill of materials (BoM) while protecting the originator’s IP because reverse engineering of the device is difficult - if not impossible - to achieve.

Customers will also choose the ASIC route to guarantee component supply for the lifetime of the product with no gaps in availability. This is in sharp contrast to a solution built using standard components whose manufacturers readily consign them to the obsolescence bin once the part no longer make financial sense to the supplier, or is superseded.

Safety criteria

Swindon is able to ensure that stringent functional safety criteria (ISO 26262) are incorporated at chip level in line with the safety case as supplied by a customer. Devices and sensors designed and produced by Swindon Silicon Systems and parent company Sensata Technologies can be found in tyre pressure monitoring systems (TPMS); the company supplies around 50% of the global demand. Swindon’s single chip devices can also be found in battery management, automatic braking systems (ABS), haptics, position and proximity sensing and touchscreen displays.

The global market for EVs will soon begin to grow significantly as the choice of make and model increases, along with the usable range and a more widespread EV charging infrastructure. EV batteries comprise many cells, which can mean large numbers of ICs in a battery pack as each cell needs to be monitored for current, voltage and temperature.

The ability to include all of the required functionality into a small single footprint, could prove to be the perfect application for a mixed signal ASIC.