Circuit protection is vital for long lifetimes in LED lighting

LEDs are widely perceived as the perfect solution for lighting applications because, in theory, they last forever. What’s less frequently spoken about is the inconvenient truth: the circuit protection measures specified can make or break the design.

There are two main places in an LED lighting system where circuit protection devices are employed. At the input, the AC rectifier will need to be protected from overvoltage and overcurrent events. At the other end of the circuit, the string of LEDs will need to be protected from overvoltages due to ESD and any elevated temperature situations. The string also needs to be protected in the event of the failure of one of the LEDs, as they are connected in series and one failure would otherwise mean failure of the whole product.

The input – protecting the AC line rectifier

The AC rectifier should be protected from overcurrent by an AC line fuse of the proper size - this is a basic requirement for fire safety. Additionally, overvoltage events may be protected against to extend the life of the equipment using a Metal Oxide Varistor (MOV), and possibly a transient Voltage Suppression Diode (TVS).

For industrial lighting, inductive load switching or capacitor bank switching could expose the lighting fixture to a transient voltage surge. An MOV or network of MOVs will clamp the voltage to an acceptable level. MOVs have a good price to performance ratio, but they do start to lose their effectiveness after many surges, so this is something to consider. These days, MOV devices with protection against thermal runaway are also available, like the ThermoFuse range from TDK/ EPCOS. These components are based on disk Varistors with diameters of 14mm (T14 series) and 20mm (T20 series) that are connected in series with a thermally coupled fuse

Consider an LED street light - if it gets struck by lightning, there will be a massive transient voltage spike that would damage the diodes in the rectifier. In this situation, as well as MOVs, a TVS is required. TVS diodes provide high performance, but they are expensive, so this needs to be balanced against the cost of replacing the light in the event of a failure.

Historically the TVS diode has been a widespread solution, however in today’s growing market for ESD protection, the MLV is increasingly becoming a standard choice of engineers.

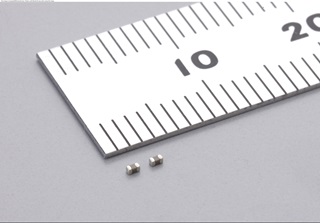

MLVs are found in many applications with improved performance, smaller space requirements, better temperature derating and a better price/ performance solution versus such diodes. For example, the TDK CeraDiode family can be used very effectively in order to meet the absorption requirements in relation to component size.

CeraDiodes also compare favourably with respect to their nearly non-derating characteristics up to 85°C. Specific CeraDiode series even feature non-derating characteristics up to 125°C or higher, offering reliability over a large temperature range. In addition they also offer a fast response time of less than 0.5ns and high pulse absorption capability over a long lifetime.

For LED ‘light bulb’ format light sources, these are generally designed to be as cost effective as possible, but for safety, a fuse and an MOV are still necessary at the input. The rest of the components in the design will generally have been specified to be operating at close to their rated voltages therefore adequate circuit protection is crucial.

Protecting the actual LEDs

Generating the light from any light fixture, there will be a string (or strings) of LEDs connected in series, driven by a constant current source of some kind. Environmental factors like vibration or heat, or even aging, can break the wire bonds inside an LED causing it to fail. Since the strings are connected in series, this can mean an open circuit, in which case all the LEDs in that string would switch off. To avoid this, voltage-triggered open LED bypass devices exist which are connected across each LED. In the event that an LED fails, its bypass device is triggered which closes the circuit. These devices are typically able to reset themselves if the LED is replaced or heals itself somehow.

The main enemy of LED lifetime is elevated temperature. Unfortunately, LEDs get hot when in use, and the excess heat rapidly reduces their lifetime. It’s important that there is some sort of mechanism that reduces the current to an LED if it gets too hot so that it can cool down to preserve its lifetime.

Methods of reducing current when the temperature rises could be as simple as introducing a power resistor that can limit current and dissipate power. A better option might be a PTC thermistor, whose resistance increases at high temperatures in order to control the LED forward current, and thereby reduce the temperature.

Depending on the characteristics of the PTC thermistor device used, they can either be used to gradually reduce the forward current with temperature, or they can switch off completely above a certain temperature. Either way, the thermistor should be mounted as close as possible to the LED itself in order to accurately determine the ambient temperature. This is easy enough for small surface-mount chip PTC thermistors such as Murata’s PRF15 series, which have detection temperatures in the range 80°C-150°C with a tolerance of just ±3°C.