UV pasteurisation tech brings significant savings

With the help of Lyras’ technology, a dairy now cuts off 91% of its energy consumption for the inactivation of microorganisms in processing water.

Inactivation now happens through UV-driven raslysation rather than traditional heat treatment. The new tech provides full microbial control whilst bringing massive energy savings and reducing the environmental impact.

Apart from nine-tenths of the energy expenditure, Lyras’ safe pasteurisation replacement, raslysation, also removes all risks of glass contamination. The raslysation system is constructed in such a way that there is no direct contact between the treated liquid, water, and the ultraviolet lamps, while a log 12 reduction is achieved on microorganisms in water.

“The dairy has replaced its pasteuriser for water treatment with a raslysation system from Lyras. This ensures the desired water quality and prevents the product from spoiling when it is flushed from tanks and pipes. The risk of glass contamination is also eliminated.” explains Senior Sales Engineer, Allan Holst Sørensen.

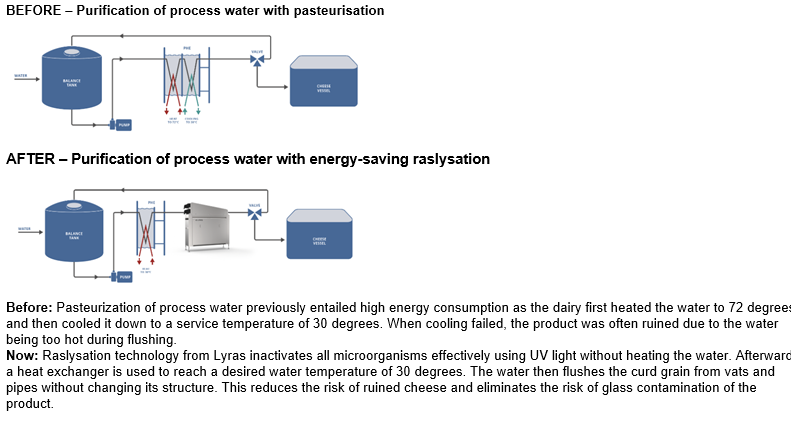

He continues: “The big energy saving is won in that the dairy no longer must heat water to 72 degrees and subsequently cool it to a service temperature of 30 degrees, which is the case in traditional pasteurisation. Instead, we effectively inactivate the microorganisms using UV light without having to heat the water. After that, we use a heat exchanger to ensure that the water has the exact desired temperature when utilized. Thus, the water flushes the curd grain out of containers and pipes without changing its texture. If the temperature is wrong, the curd grains retract, ruining the structure of the cheese. With the new raslysation system, the dairy saves energy and money while eliminating the risk of glass contamination and ruined cheese.”

After less than a year, the dairy has earned back its money based on the energy savings alone. After that, the decreased energy consumption will result in pure profit. It is a win-win for all parties, even the climate, as the dairy now emits far less CO₂. Since raslysation only needs electricity, the technology provides a basis for applying for government subsidies.

Valuable proteins are protected due to full microbial control

Raslysation also secures high product quality in opaque liquids like brine, whey, blood plasma, protein solutions, juice, and industrially fermented liquids. Because heat is avoided, the product’s valuable proteins are kept in their original form. When the technology is used as a replacement for depth filtration of for instance enzyme solutions, the production process gains higher yield and an increased level of automation.

Lyras’ goal is to implement raslysation across the global process industry and thereby both contribute to reducing the world’s total CO₂ emissions and to increase food safety globally. Raslysation systems are already installed in companies across Europe, Australia and the USA.

Inactivates all microorganisms effectively

Food business operators have various requirements for the quality of the processing water. Usually, you have separate water sources and analyse their quality as part of the manufacturer’s own checks. Since water is often an integral part of food production, the water must be completely clean, for example when it is used to empty tanks and vats for curd grain, when flushing product from process pipes as well as for processing water in cheese production. Raslysation effectively inactivates all microorganisms and can therefore often fully replace the traditional heat treatment of both water and product.

BEFORE – Purification of process water with pasteurisation

Facts about Lyras and raslysation

Lyras has developed and patented raslysation, which inactivates microorganisms in both transparent and opaque liquids using UV light. The method is far less energy-intensive than traditional pasteurisation and filtration. With raslysation, you therefore save between 60 and 90% energy and 60 to 80% water compared to traditional pasteurisation. For example, if a cheese dairy treating 40 tons of whey an hour switches from pasteurisation to raslysation, it will save approx. 87% energy, equivalent to four million kWh per year and, based on the EU average, an annual CO2 emission reduction of 950 tons. This is equivalent to driving around the world 184 times in an ordinary gas-powered family car.

Raslysation uses a UV light source, combined with a light filter sorting off the unwanted wavelengths. The liquid is led past the light source in a continued, controlled movement making sure that all product is illuminated. All unwanted microorganisms are thus inactivated effectively.