Software-defined infrastructure in industrial IoT: How it works

Previously the idea of a software-defined infrastructure approach driving and accelerating digital transformation in industrial automation had been mentioned and introduced.

Guest blog by Gareth Noyes.

This is because it offers a more flexible, adaptable and cost-effective alternative for developing automation systems leveraging the Industrial Internet of Things (IIoT). In contrast to conventional single-vendor, proprietary automation solutions, open software-defined infrastructure platforms allow for a higher level of interoperability among commercial-off-the-shelf (COTS) components from multiple vendors, giving industrial users more choice and flexibility. It would also make it easier to upgrade systems and add features to keep pace with changing market demands – all at a lower initial and ongoing maintenance cost than proprietary systems.

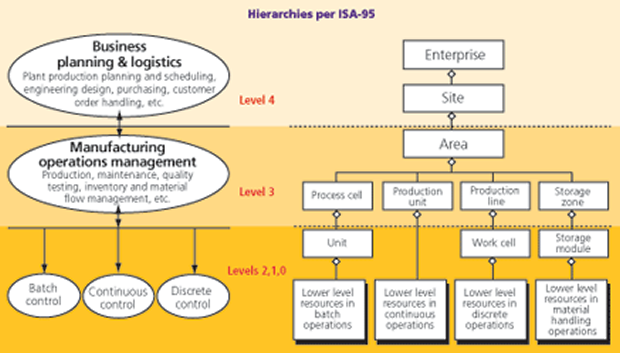

Let’s take a closer look at how a software-defined infrastructure approach would work in an industrial automation application. The International Society of Automation’s ISA-95 model, a standard for integrating enterprise and production control systems, is comprised of four levels as illustrated below. Levels 1-3 represent the operations and control functions, while Level 4 is the enterprise-level business planning and logistics layer. The premise of software-defined infrastructure in automation is that most of the functions found in Levels 1-3 can be run on COTS servers capable of satisfying the real-time performance requirements of industrial environments.

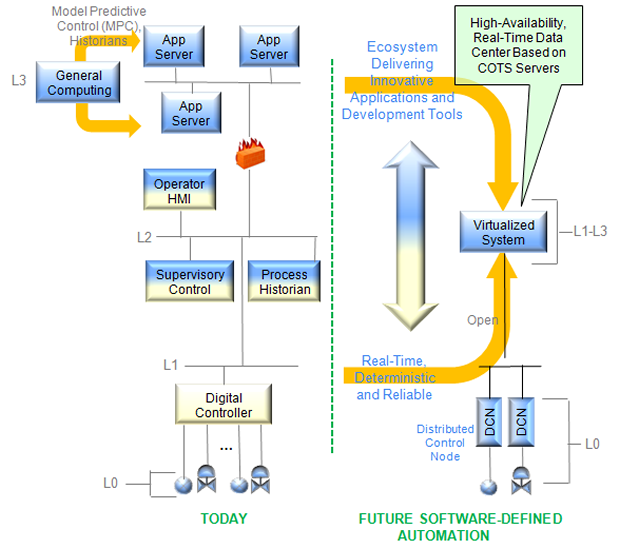

More specifically, as illustrated below, software-based digital controllers, PLCs/DCS, SCADA software, HMI, process historians, and applications in L1-L3 can run in an industrial software-defined infrastructure. Servers interface to sensors, actuators, and other physical industrial devices via distributed control nodes.

In contrast to a typical IT data centre installation, software-defined infrastructure makes the data centre ‘industrial grade,’ delivering the CapEx and OpEx benefits of an IT-based approach while satisfying such industrial requirements as high availability, real-time determinism, life cycle management, and hitless upgrades.

Compared to purpose-built proprietary solutions, software-defined infrastructure can deliver a number of cost-reducing benefits. It can lower hardware CapEx by substituting low-volume, custom computing platforms with a small set of high-volume COTS servers. These servers can be easier to manage than a large number of unique proprietary devices, which results in lower OpEx.

Software-defined infrastructure would further lower CapEx and OpEx for logistics by significantly reducing the number of unique boxes that must be kept on hand for maintenance and the related costs to train and support staff on a number of unique articles.

A software-defined infrastructure approach has the potential to scale and expand with less effort because there are fewer wires, cables, and systems to deal with, minimising connectivity related costs. Software-defined infrastructure solutions also take up less physical space near the industrial equipment they control.

By design, software-defined infrastructure -based systems require less field service support than traditional systems. In an industrial IoT environment, operators can monitor, diagnose and update software-defined infrastructure systems remotely and in real time, without deploying engineers, further reducing OpEx costs. If a failure occurs in the field, high-availability system failover mechanisms help reduce the need for an emergency truck roll.

Finally, having a software-defined infrastructure can mitigate the costs of avoiding system obsolescence. The decoupling of functions implemented in software from the underlying hardware and software platforms makes it easier to update systems over their expected service lifetimes.

When you combine the cost benefits with the added flexibility and the ease of keeping pace with technological innovation, the case for software-defined infrastructure as the next wave in industrial automation becomes quite compelling. In a future entry, we’ll explore what is required of a software-defined infrastructure approach in order to realise these benefits.

In the meantime, you can check out Wind River has a microsite with more information: http://windriver.com/iiot/.

Courtesy of Wind River.