Bridging tracks and tech with embedded computing

Modern railways are seeing enhanced efficiency, safety, and overall performance of daily operations thanks to the continuous advancements in technology. At the heart of its ongoing progression is the use of embedded PCs.

Compact computing systems drive the railway industry towards new levels of automation and intelligence, designed to operate seamlessly within railway infrastructure and revolutionise how we manage today’s rail networks.

These ruggedised PCs provide essential solutions such as real-time monitoring, predictive maintenance, optimised logistical operations, improved passenger safety, and more. In this article, Impulse Embedded will cover the significant benefits embedded PCs enable, exploring the diverse applications and improvements that sophisticated computing systems bring to the tracks in the 21st century.

A brief history of rail

Before railways, we had horse-drawn carriages (at least, the wealthy of the time did – the rest of the population relied on walking to get from A to B). Among the oldest continuously working railways in the UK are Tanfield Railway in County Durham with a section of the track dating back to 1725, and Middleton Railway, founded in 1758 in the city of Leeds. Middleton Railway was initially constructed with wooden tracks before being upgraded in 1799 with iron edge rails. It was the first railway to successfully use Salamanca, the first commercial steam locomotive in 1812.

Years later, electronic power was introduced to the railway with the first known electric locomotive built by chemist Robert Davidson in 1837, which was powered by galvanic cells. This was followed by the first diesel-powered locomotive in 1912. The first high-speed rail was introduced in 1964 in Japan, bridging the gap between Tokyo and Osaka. Since then, high-speed rails have been integrated into countries worldwide, including Spain, France, Italy, the UK, Taiwan, and Scandinavia.

High Speed 1 (HS1), also known as the Channel Tunnel Rail Link (CTRL), is a high-speed rail link between London and the Channel Tunnel that spans 68.3 miles and splits into two sections. Section one, spanning 46 miles from the Channel Tunnel to Fawkham Junction in North Kent, opened in September 2003. Section two opened four years later in November 2007, spanning 24.5 miles between Ebbsfleet station in Kent to London St Pancras.

The success of this railway line saw the travel time between London and Paris reduced to only two hours and 15 minutes, leading to plans for a second UK rail link, the High Speed 2 (HS2). Initial plans for the new rail were investigated in January 2009, with confirmation in 2012 that plans would be going ahead, comprising two main phases. Despite the success of HS1, HS2 proved controversial due to environmental and economic concerns, leading to the cancellation of the entire second phase of the rail. To this day, only phase one – a link between Birmingham Curzon Street and Old Oak Common in London – is planned for completion between 2029 and 2033.

When we look at our history, it can be hard to believe how far modern railways have come. And yet, this is often overlooked due to how readily available and commonplace these innovations have become, leading many of us to not give this mode of transport a second thought beyond when our train is due to arrive.

Transforming the modern railway

To help understand how far the rail industry has come from its rudimentary beginnings and the pivotal role that PCs play in their development, we can also look at the history of embedded systems. The first embedded system was the Apollo Guidance Computer (AGC) from 1966, a digital computer produced for the Apollo program that assisted with the navigation of nine flights and six successful moon landings. While perhaps not a powerful PC by today’s standards, the AGC was the first computer built with silicon integrated circuits and stands as a benchmark that paved the way for today’s robust embedded systems and the capabilities of ruggedised technology.

Today, industrial devices and embedded systems are used in our railways to manage the Wi-Fi, the Train Communication Network (TCN), CCTVs, Driver Advisory Systems (DAS), condition monitoring, ticketing, Passenger Information Systems (PIS) and more. Using technology to assist with daily operations, from simple applications to safety-critical systems, has improved our efficiency and our daily lives. This includes that of engineers, conductors and, most importantly for rail operators, the passengers on the railway.

Onboard innovation

As the railway has advanced over the years, the technology both onboard and at stations has also improved in leaps and bounds, leading to the innovative and efficient solutions we have today and providing considerable benefits to commuters. It makes perfect sense that computers are at the heart of these improvements as the rail industry embraces steps towards a digital railway. Some of the most common computing devices used in railways are:

- Railway embedded computers: embedded computers are designed to be integrated into larger systems or devices for specific tasks. These small form factor PCs have powerful passively cooled processors, a wide range of inputs and outputs, support wide voltage DC (Direct Current) power input to make them suitable for use on different types of rolling stock, and are designed to work in extended temperature environments for further protection.

- Railway rack-mount computers: rack-mount PCs are much larger than embedded PCs and are designed to be mounted in standard 19” server racks. This makes them more scalable, allowing for the addition of multiple units within a rack to meet increasing processing or storage demands for railways.

- Railway panel PCs: panel PCs (or HMIs) have all the essential components of a computer system, including the monitor and computer system unit, all rolled into one device. These computers can also include touch screen overlays, making them especially useful as in-cab Signal Interface Displays (SIDs) or interactive Passenger Information Systems (PIS). They can display information such as dynamic train schedules and other vital alerts to passengers, both inside the train and at railway stations, as well as information to the train operator.

With any embedded computer system, connectivity plays a pivotal role in establishing communication and data exchange between different subsystems. Modern railway computers are Ethernet-enabled, with speeds that reach 10GB and beyond. Through Ethernet technology, computers on board trains and within railway stations can interconnect, allowing real-time transmission of critical information. These interconnects allow high-speed, secure, and reliable networking, enabling efficient communication between railway subsystems, which ultimately contributes to the safety, reliability, and effectiveness of the whole railway.

Embedded computers can also use wireless networking functionality through Wi-Fi or cellular, which can enhance the efficiency of carriage-to-carriage and train-to-ground communications and enables over-the-air (OTA) updates to firmware and software. This technology not only allows operators to provide passengers with secure and environmentally friendly transportation while offering appealing onboard multimedia services, but also facilitates communication to station-based signage and cloud storage infrastructure with critical system information.

Rolling stock standards

RCS, or Rail Compliance Standards, are implemented to ensure that all electrical equipment on rolling stock or railways adhere to strict safety regulations. In particular, EN50155, EN50121, and EN45545 are important standards in Europe and the UK to regulate railway equipment in parameters such as ruggedness, electromagnetic compatibility, and fire safety.

EN50155 for onboard systems

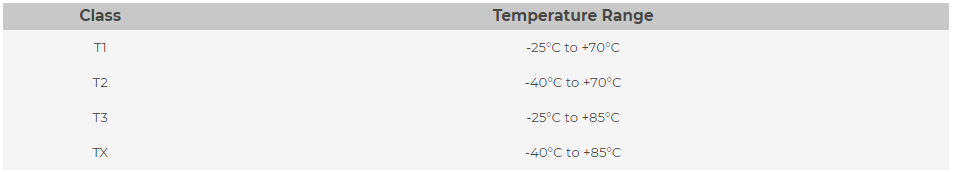

This standard regulates heat, shock, and vibration resistance, as well as the quality of the power supply, a critical component in trains and adjacent equipment. Systems must be operable in a wide temperature range, given the industrial nature of the railway, and the EN50155 standard distinguishes the temperature ranges in a number of temperature classes, including:

In addition to heat, it’s also important that the onboard devices can accept a wide voltage input, as is found in many of our rail-approved devices ranging 24v – 110v. This wide DC power input ensures that the computer system can support the wide variety of rolling stock currently used in the UK today, and removes the requirement for separate, and often expensive railway approved DC/DC converters.

It is imperative to use ruggedised equipment that is sure to last in extreme environments over extended periods, especially considering vibration and humidity are ever present in the railway environment. Corner bonding, underfill, and conformal coating are solutions that can ruggedise embedded PCs.

Corner bonding and underfill create a strong bond between the PCB (printed circuit board) and its components, sealing them together with fewer gaps that help to prevent damage in environments with high levels of shock and vibration – while corner bonding only seals the corners of the component, underfill covers each edge for a complete seal which is then cured with UV light.

Conformal coating can be made from various materials, including acrylics, silicones, urethanes, or epoxies, and protects the circuit board from harsh operating conditions and environmental factors, helping to keep moisture at bay and making water damage less likely. While this can’t guarantee IP rating conformity for water resistance, it can help to strengthen the circuit board considerably for industrial purposes.

M12 connectors, named after their metric thread size of 12mm, are a type of circular electrical connector commonly used in railway applications because they meet the criteria specified in EN50155. The connectors are designed to withstand the harsh environmental conditions associated with railway operations, including temperature variations, moisture, vibration, shock, and mechanical stress. The lock and seal mechanism on M12 connectors means they do not come loose with vibration and prevent dust and water ingress, which is particularly important when considering the numerous I/O ports featured on railway embedded computers.

X-coded M12 connectors and cables can also improve Ethernet data speeds for railway applications, as these are designed to reach up to 10GB/s compared to D-coded cables, which can only reach up to 100MB/s. This is achievable because X-coded cables have an eight-pin configuration that is designed to support high-speed data transmission versus D-coded cables’ fewer, four-pin configuration. The higher data transfer rates and eight-pin configuration of X-coded cables make them versatile for a range of onboard applications where fast and reliable communication is crucial.

EN50121

Another essential railway standard is EN50121, which relates to the Electromagnetic Compatibility (EMC) of electronic and electrical systems within railway applications. Complying with this standard helps to prevent interference issues and maintain the reliable and safe operation of railway infrastructure and rolling stock. This adherence ensures that all systems can operate together without being susceptible to electromagnetic disturbances.

EN45545

First published in 2013, the EN45545 standard dictates the fire behaviour requirements of railway vehicle products. To comply with this vital safety standard, the equipment used in trains, including electrical devices, must meet specific criteria such as heat release and the flammability of materials used in construction. Computers and similar devices, for example, will need to use approved adhesives and sealants to protect electronics in order to be compliant with the EN45545 standard. This is done to reduce the risk and impact of fire-related incidents in railway applications, protecting passengers and staff.

Using AI for smarter travel

In addition to the tremendous benefits that traditional CPU based embedded systems bring to the railway, GPU (Graphics Processing Unit) based computers are now being used with AI to bring a new level of safety, security, and reliability to the railways.

Using intelligent video analytics (IVA) solutions (AI inference algorithms deployed on Edge computers), railway companies can automatically detect obstructions on the track, identify security threats, catch fair avoiding passengers, and monitor critical assets such as the pantograph, and even the railway tracks themselves.

AI algorithms can be employed within train carriages, analysing real-time data to monitor various factors such as temperature, luggage status, and passenger occupancy. This information can be used to optimise climate control systems, ensure a comfortable environment for travellers, and identify lost or unattended items. More crucially, this analytic data can contribute to predictive maintenance by continuously monitoring the condition of critical components, thus reducing the likelihood of unexpected breakdowns.

Railway solutions with industry insight

With experience providing thousands of devices to TOCs and rail services companies across the UK, and with a vast array of solutions available for a whole host of different applications, Impulse are fully equipped to assist with railway projects from AI to Z. We also offer lifelong technical support for all our embedded systems and PCs so that nothing unexpected will derail your project plans.

For more information about our work within the railway industry, visit our Railway sector page or contact us directly.