M&A and the rise of the counterfeiters

The electronics industry has experienced a huge rise in merger and acquisition activity over the past 18 months and this has in turn opened another door to counterfeit products coming onto the market. Here, Electronic Specifier Editor Joe Bush talks to Astute Electronics Managing Director Geoff Hill about the dangers in the current market and what the company can do to help.

The raft of mergers and acquisitions within the electronics industry over the last year or so, has led to many product lines being absorbed or discontinued, with an astronomical number of Last Time Buys leaving fewer and fewer outlets for OEMs. This creates an opportunity for counterfeiters seeking to fill that gap in the market. This is a trend that is likely to continue as distributors look set to make further acquisitions in 2016.

Astute Electronics provides component supply and logistical solutions primarily to the aerospace and defence industry. This, combined with the company’s AS accredited anti-counterfeit mitigation programme, means it is well placed to combat the issue of obsolescence and the rise of the counterfeiter.

Clearly, the consequences of a counterfeit product making it into the defence sector are potentially catastrophic, however, the UK and the US governments (Astute’s largest customer locations), have very different approaches to mitigating risk, as Geoff Hill, Managing Director of Astute Electronics explains: “People are going to prison for a long time in the US due to counterfeit products. The US approach is rigours, legislative, internationally far reaching and highly punitive, making the supply of counterfeit products or systems containing the same punishable with a $30m fine and up to 25 years in prison. It is possibly because their supply chain isn’t as robust as the hi-rel marketplace here in the UK that they are taking that approach.

“However, in the UK the approach is to let industry self-govern, providing its own control programmes, with little or no changes to legislation. In the UK the only thing that companies are being indicted on is IP infringement which carries a fine of around £1,500 - so there’s little deterrent.

“So both governments don’t actually deal with the problem properly - one reduces the number of companies willing to support hi-rel industry because of the fear factor, and the other doesn’t engage with industry to solve the problem at all. We need a balance between the two, and that comes from accreditation.”

Testing, testing

Hill continued: “We have AS6081 and all the accreditations from a global standpoint. We’re also the only distributor to have test labs in both the US and EU. The role of the test lab is to sniff out counterfeit products – primarily for programmes suffering from obsolescence but also you may get supply chain shortages or long lead times where it’s necessary for the OEMs or CEMs to buy from outside of traceable sources - thus increasing risk.”

Astute’s testing practice identifies four sources of product – Route A is direct from the manufacturer, Route B is franchised distribution, Route B1 is catalogues and Route C is untraceable – and the sheer number of Route C products coming into Astute’s Hertfordshire-based test lab is highlighting the issue that merger and acquisition activity is creating.

Hill added: “We would of course rather supply fully traceable product because it’s cost effective for all of us. However, we have a huge number of Route Cs coming through at the moment – which means non-traceable product. You can get good and bad Route Cs but it’s a source that you just can’t trust so it has to go through the test lab. Some people say that they can supply the paperwork to verify a product, but how do they know that the paperwork itself isn’t counterfeit. If you can produce counterfeit product to the level that we’re seeing, which is ingenious, then the paperwork should be child’s play.”

Counterfeit source

Hill is in no doubt as to the origin of any counterfeit products on the market, adding: “Let’s not kid ourselves, all counterfeit products are sourced indirectly from China. It’s off the charts and the Chinese government is only just starting to do something about it as they begin to enter into aerospace manufacturing, and are thus starting to understand the risks.”

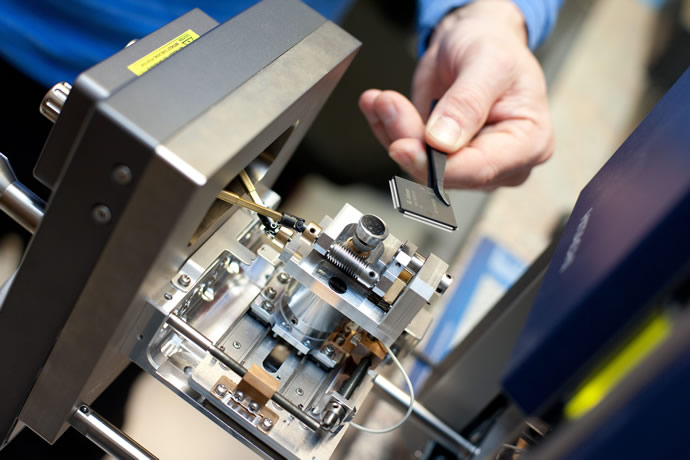

“Astute’s business is all about mitigating risk. The testing procedure isn’t cheap and there’s not one particular piece of equipment at the company’s test lab that on its own deduces if a product is counterfeit. Hill continued: “It’s a case of eradicating anything that’s a concern i.e. most counterfeit product has been remarked. So we have scanning electron microscopy and energy dispersive spectrometery to observe both the structural and elemental condition of the device packages. Our staff have been trained to recognise the difference between OCM and counterfeited conditions.

“We have die recognition through decapsulation (observation of the silicon die), x-ray which reveals the bond wire connections and internal structural consistency of the batch, XRF which measures the plating thickness and elements present on the component terminations (as counterfeiters tend to thin down the lead thickness to hide signs of re-work). There’s more besides that with the addition of a lot of equipment over the last few years.”

Meeting the needs of the market

Although Astute’s testing lab has been in place for some time, what’s different in today’s market is that the need for testing has been accepted and recognised by the marketplace, as counterfeit products become more prominent. What is also new is Astute’s achievement of AS6081 counterfeit mitigation accreditation - with AS6171 test specification due to follow later this year.

In addition, what sets Astute’s test lab apart from a standard test house is that the latter will carry out the functionality and then let the OEM make the ultimate decision on whether or not to use a particular product. However, most OEMs haven’t got the experience to make such a decision. Hill added: “If they come to us, we make the decision for them so the value of the role we play is huge. What we do is a fine art - it’s not easy - it’s a huge responsibility and is too costly and too high risk for most companies to do, plus it’s a tough ask for the inspectors. Indeed, when we first started there weren’t any counterfeit inspectors, so it’s something we’ve had to train to do ourselves.

Summary

Hill concluded by stressing that counterfeiting is a problem that can be managed, but a solution will never be found as long as obsolescence exists, as the two go hand in hand. Because of the way Astute’s business is set-up i.e. in the aerospace and defence industry, counterfeiting is a problem that the company had to deal with early on and that ability is now a differentiator.

The company was also the first distributor to receive the SC21 award (initially bronze, now silver) - a change programme designed to accelerate the competitiveness of the aerospace and defence industry by raising the performance of its supply chains.

Hill continued: “SC21 is in its tenth year and of the 6,000 or so suppliers serving the aerospace and defence industry, there’s still only 125 companies that have the award. It’s an award that is constantly monitored and part of achieving it is having a continuous improvement plan in place. It’s brutal - every year we’re challenged - we supply thousands of items into key channels that are monitoring us. It is good for the business however, because it gives us the disciplines, processes and the management structure we need to meet our aspirations going forward. However, just 125 accredited suppliers in ten years is a disgrace and therefore, it’s up to OEMs to do their due diligence and make sure they’re picking the right suppliers. It’s imperative that any distributor in any market has the technical capability to add value and we’re increasingly being invited to provide that technical capability and expertise.”