Breaking the battery barrier to innovative medtech design

Technology advancements are driving manufacturers to create—and people to expect—products that enable greater functionality, more convenience, and quick results. This is apparent in all aspects of work and daily life, ranging from consumer products like smart phones and watches, to blockchain, cloud services and, at the enterprise level, smart factories. The medical field is no exception.

By EJ Shin, Managing Director, Jenax

A significant trend in the medical industry is a shift from public spaces to personal spaces – from hospitals to homes. According to Forbes, even digital marketplace providers such as Amazon, Google, Apple, Microsoft and IBM, are entering the home health space, bringing accessibility and affordability of care.

The medical market is showing promising growth. The global medical device industry is projected to reach $409.5bn by 2023, at a compound annual growth rate of 4.5%. The homecare medical equipment market is expected to grow at CAGR of 7.1% from 2017 to 2023, to $35 million. With this changing healthcare structure, demand for personalised and connected devices that can continually track and transmit user data to networked systems and clinicians is rapidly increasing. With that, two major trends driving medical device design are worthy of exploration: personalisation and IoT-driven complexity.

Device design necessities

What kind of products are required to meet the needs of personalised, connected healthcare? Smart wearables and IoT devices that not only make it easier to track users’ biometrics and progress in hospitals and homes, but also make home care treatment more effective and, therefore, possible.

Advanced user-centric devices can also enable the healthcare industry to progress to analysing current body conditions and accumulated data for preventive measures. In this way, device sensors are not only used for monitoring the recovery of ill patients, but also for catching unusual data or symptoms in people who are not already sick or injured.

What happens if there is a medical device with rich features for monitoring patients and providing preventive alerts, but it is awkward to wear or move around for elderly, very young or other patients? Who is at fault if they don’t use it and, as a result, their health suffers? Not the users.

If people cannot use a product correctly, the fault lies with the device designers. Clearly, wearables need to be comfortable to encourage frequent use. If consumers do not regularly wear them, less data will be collected. As a result, they will obtain non-valuable or, worse, inaccurate analysis and recommendations that can harm patient care. Simply, intuitive design would improve both adoption rates and likelihood of successful therapy.

The battery barrier

The need for personalisation and the use of IoT-connected devices that have greater functionality and require continual uptime are creating new challenges for device design engineers – and putting the spotlight on the limiting nature of today’s batteries.

Rigid and bulky battery shapes are often a hindrance to the comfort of wearables and the usability of IoT devices. The reason smart watches and other smart devices are so popular is because they improve and ease daily lives. However, rigid and bulky batteries are thick and unbendable and, therefore, challenging to shape into well-designed, portable and helpful products.

Imagine the impact of battery-restricted smart wearables on patients’ lives. Let’s take a look at James as an example.

James is a 70-year-old stroke survivor. He lives alone. James’ doctor ordered a wrist monitor with a conventional—thick and rigid—battery to check his blood pressure and pulse. It sends an emergency signal if he appears to be having another stroke.

But James doesn’t like wearing the monitor because it is thick due to battery placement and, therefore, gets in the way of his daily activities. Because of this, he often goes about his day without the wrist band. Making matters worse, his doctor prescribed daily medication, but James sometimes forgets to take his pills.

What if James were to have another stroke when driving and forgot to take his meds and wear his wristband? Hopefully, he would not get in a bad accident and would not miss getting the fast medical attention required to improve his chances of recovery. In any case, he would likely be forced by his daughter—Sophia—and his doctor to give up driving due to high risk.

Sophia now has to drive her father wherever he needs to go. This is especially difficult because she has been going to physical therapy for an arm injury. Her doctor recommended wearing a band that monitors muscle condition so she wouldn’t have to drive to the clinic for weekly checkups. However, because the arm band is uncomfortable, she only wears it for two hours at home after work. Two-hour usage does not collect enough data about her physiological movements, making it difficult for her doctor to see trends and progress.

Battery advancements break the barrier

How can we resolve the challenge of batteries being an impediment to IoT and wearable medical devices? By having a much more pliable, adaptive form factor. They must be thin and flexible, as well as powerful and rechargeable, so they can be used to design highly compelling wearable and intuitive non-wearable devices.

The good news is that a new generation of lithium-ion batteries have the flexibility required. They can bend and roll in any direction and even scrunch like paper. One of the biggest differences between these next-generation batteries and the conventional batteries are the former’s ability to withstand pressure at various degrees and still perform as expected.

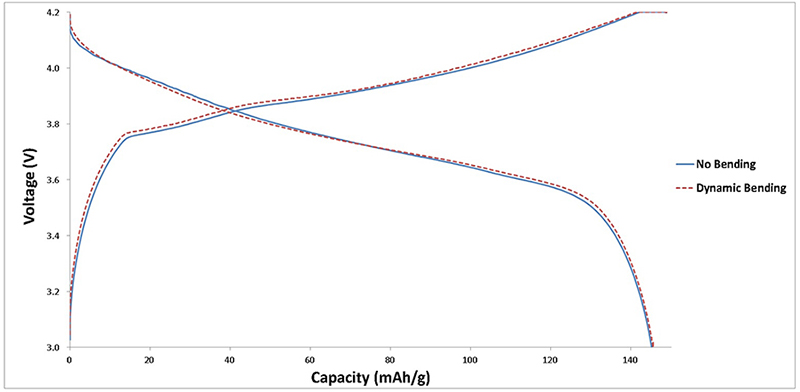

For instance, Jenax’s J.Flex battery, which was tested by bending 10,000 times, proved to have essentially the same capacity as that of a non-bent battery. Tests such as this show that device designers do not have to sacrifice performance for flexibility in energy storage.

This flexibility is essential for products that are bendable or curved. It is also critical for non-wearable devices, making batteries easy to integrate into existing equipment and transform them into smart, IoT-connected devices. Flexible batteries are as thin as 0.5mm to 2mm. This allows them to be seamlessly implemented in the device and to enable a comfortable wearing sensation.

Look for customisable flexible batteries that can be made available in different sizes, shapes and capacities, according to specific needs of device manufacturers. With this capability, device designers are no longer restrained by the fixed sizes and shapes of the conventional batteries. They have much greater freedom to design innovative, user-friendly medical and IoT devices.

One more essential factor to consider when evaluating batteries for medical and other devices is safety. Safety is clearly a key concern for both manufacturers and consumers. Especially with wearables that contact human bodies, it is important to ensure dangerous battery elements do not put users at risk.

Generally, lithium-ion batteries contain liquid, solid or gel electrolytes. The most common form of electrolytes for such batteries is liquid, which can leak and easily ignite when overheated. This is the main cause of many accidents and, understandably, renders liquid-electrolyte batteries a sub-optimal option for next-generation medical devices and smart wearables.

Solid electrolytes, on the other hand, are a safer option as they are non-flammable. However, this safety feature offsets performance because of the electrolytes’ lower ionic activity. Additionally, solid ceramic batteries do not deliver the flexibility required for wearables and innovative IoT uses.

Gel electrolytes provide the best of both worlds for medical wearables and IoT, delivering both safety and flexibility. Due to the gel form factor, even if the device is pierced or penetrated, there is no electrolyte leaking and, therefore, minimal risk to consumers.

A new day in the life

How could James’ daily life be enhanced if flexible batteries are integrated to his medical wearables?

If James’ wrist band is powered by a thin, rechargeable, flexible—and therefore unobtrusive—battery, he would be comfortable wearing it. It would become his habit to continuously have it on.

If James happens to have a stroke while driving, his wrist monitor could instruct sensors in the car’s breaks and tires, which could also be powered by flexible batteries, to safely stop the vehicle. The monitor would also alert his doctor and trigger a text message to Sophia.

James would also be wearing a smart transdermal patch, powered by a thin flexible battery, which seamlessly contours to his arm. The patch would immediately release an emergency dose of a blood pressure-lowering drug and write it into James’ 24/7 medication log.

James’ intelligent medical wearables could also assist him between doctor’s visits. His wrist band would send blood pressure readings to the nurse, and smart patch medication would release necessary doses on schedule, collecting precise data on the hospital server. Alerts would notify the doctor if James’ blood pressure moves outside the normal range.

Meanwhile, Sophia is happily wearing her smart arm band, powered by a flexible, rechargeable gel-electrolyte battery, which sends continual progress information to her physical therapist and doctor. She spends less time at office visits and more time healing.

As one can see, advances in thin, flexible batteries are taking the shackles off design engineers. With batteries no longer a limiting factor, medical device manufacturers now have the right energy solution in hand to deliver cutting-edge devices in a medical industry driven by personalisation and IoT-driven complexity. With flexible batteries, they are free to innovate smart, high-performing and feature-rich connected products that are extremely comfortable, reliable and safe. The possibilities are endless.