The servo motors that help produce the robots

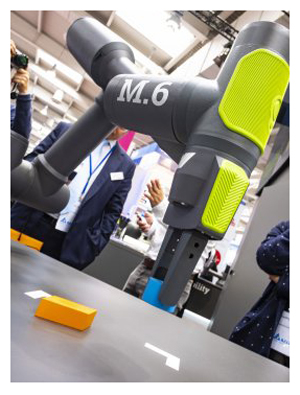

At the Hannover Messe trade show earlier this year, collaborative robots were a big feature. Small, intelligent, sensitive, and self-learning: The ways in which robots can be used are increasing all the time. And the level of acceptance is also rising - not least thanks to attractive prices and short ROI times. Off-the-shelf handling solutions are in demand and Yuanda Robotics has a range of market-ready robot systems.

For its drive technology, this young company from Hannover depends on the robotics expertise of KOLLMORGEN. You know about its horses, now they are here to tell you where its power comes from.

With slogans like this, Lower Saxony is confidently advertising its own innovative strength - something which is most apparent in its robotics expertise. The region's claims to market leadership were once again made clear at the Hannover Messe 2018 - not least in the shape of start-up company Yuanda Robotics. Founded just over one year ago, the company exhibited a number of robots for performing various load-carrying tasks. Inside, they are powered by specially customised servo motors from KOLLMORGEN's KBM range. What is remarkable about these is that the powerful synchronous machines are frameless and can be embedded in the construction of the robot straight from the kit. The main advantages of this are that it saves space, and heat can be extracted far more efficiently.

Better ergonomics

Jens Kotlarski likes to lead his new robots by the hand.

"In the same way as I would show things to my child, I show them to the machine," said the managing director of Yuanda Robotics - a successful spin-off set up by three scientists from the Leibniz University in Hannover with funding from the Shenyang Yuanda Aluminium Industry Group in China. The company from Hannover is aiming to successfully bring different types, such as the L.3, M.3 and M.6 versions which, they exhibited, to market by the end of the year. The robots are designed to act as automated handling assistants for manual assembly lines in industry.

"That's why our robots have a similar reach to the human arm," explained Kotlarski. "Humans are not really able to move loads of 5kg or more ergonomically for long periods - especially if the parts also have to be lifted from low down to high up".

For example, one specific area of use for the new robots from Hannover would be the loading of machines. Insert the component, press the button, wait, remove the component, and put it in a box - all day long. These are monotonous tasks that are avoidable. Kotlarski believes that people can be used far more cost-effectively in other ways. Before setting up Yuanda Robotics, he worked as a group leader at the Institute of Mechatronic Systems at Leibniz University in Hannover. The first ‘Made in Hannover’ robots are principally designed to serve as production assistants for continuous operation. Among other things, using them in this way raises the question of how the heat from the drive technology can be most effectively dissipated.

High power density

This is where the frameless structure of the KOLLMORGEN KBM motors can improve heat extraction simply by convection across the robot's joints. The effect of these excellent thermal properties is that the KBM motors can reach peak performance without derating.

"The high power and performance density were important reasons why we used these motors," explained co-founder Matthias Dagen. Small motors with a high output are essential if the arms and the joints are to be made as compact as possible. "The thinner and more lightweight the design, the heavier the loads that the robot will later be able to carry," explained Dagen. Overall, it improves inertia behaviour and the ratio between the robot's own weight and the weight it can carry.

Nevertheless, the requirement for lightweight construction has its limitations because a certain surface area and mass are needed in order to dissipate the heat effectively. But this is where the KBM motor assemblies from KOLLMORGEN prove to have particularly robust thermal properties.

Nevertheless, the requirement for lightweight construction has its limitations because a certain surface area and mass are needed in order to dissipate the heat effectively. But this is where the KBM motor assemblies from KOLLMORGEN prove to have particularly robust thermal properties.

The stator winding has been defined by the specialists in servo drive technology and motion control as having continuous capability at an internal winding temperature of up to 155°C. Aspects such as this were crucial criteria when the motors from the KBM range were being designed and dimensioned. There was close cooperation on the engineering between Yuanda Robotics and KOLLMORGEN - mainly in the person of KOLLMORGEN project manager Markus Grohnert.

"Having a personal contact was also important to us when we were choosing the most suitable drive manufacturer," emphasised Matthias Dagen. In addition to the strict performance criteria, delivery times for the components were another key factor for the young startup company. "We need to be able to rely on short timeframes, if we are aiming to bring new products to market quickly," said Kotlarski.

Quick delivery for quick startups

The short delivery times for the frameless motors in the KBM series are mainly possible because each bespoke drive system is the result of a clever combination of standard components. Refinements can be made, for example, to the rotor hub dimensions, stack length, diameter, assembly jigs, windings, connection type, and much more. Part of the work of the engineering project at Yuanda Robotics consisted of Markus Grohnert making sure that the direct drive was perfectly matched to the intended robot gear system.

When it comes to control units, by the way, despite the ready availability of products that have been tried and tested in industry, Yuanda Robotics relies on in-house development. "We are aiming for a highly integrated solution that can't be achieved with standard control units - in terms of function or price," explained Matthias Dagen. The main reason for this is the special algorithms which are supplied to the control unit.

Kotlarski said: "To do that, we have to go deep into the control technology and we want to eliminate all the superfluous functions that standard control units inevitably bring with them." The two men are happy that they are able to bring to market a solution that has been deliberately reduced to the essentials. Both are in agreement: "KOLLMORGEN's experience with frameless direct drive motors made them perfect partners for us in this kind of robotics work, including on the electro mechanics."

The bottom line

With the new series of robots, the company from Hannover is marketing a solution that provides everything that is needed to automate assembly and handling tasks quickly and reliably. The overall package is nicely rounded off by the integrated camera technology in the robot. This enables the robot to identify the products it needs to pick up by itself. For the visualisation, the company has taken advantage of the potential of so-called augmented reality.

This means that, when the parameters for new tasks are being set, the movements of the robot in the workspace can be exactly simulated - and then they can be sent out to start production. Helping people to understand these complex systems is one of the main objectives for Yuanda Robotics, in the hope of further increasing the acceptance of robots.