New possibilities for the automotive industry in parallel kinematics

Industry is looking for new forms of robotics. In particular the automotive industry is searching for alternatives and additions to the classical industry robots. For many years, hexapods were considered to be exotic in automation but now, many applications are beginning to confirm the capabilities of the parallel-kinematic six-axis positioning systems.

Because they are able to communicate directly with the PLC or CNC controller via fieldbus interfaces, it is easy to integrate them into the automation environment.

They are just as predestined for tasks in quality assurance and production technology as they are for prototype construction and use on the production line. In this case for example, they are able to supplement the classical industrial robot or work together with the worker in partially automated processes.

The range of models from car manufacturers is increasing. The car is becoming the smartphone on wheels. Because customer requirements can change very quickly, development times are getting shorter. Newer models must get onto the market earlier and updates must be made available much quicker. Suppliers and car manufacturers are therefore relying on a new generation of automation. Hexapods as high-precision, parallel-kinematic positioning systems can play an essential role in this case. The robots have travel ranges from just a few to several hundred millimeters. They are even able to position heavy loads of several tons with micrometer precision and are suitable for precision handling of the smallest components and for positioning entire body parts. Furthermore, they can be operated together with the worker without additional safety measures.

The automotive industry has been familiar with the advantages of parallel kinematics for a long time. Indeed, in the early part of the 20th century, Dunlop made use of hexapod technology for testing car tires. At that time, Dr. Eric Gough, the father of the hexapod, was working for a tire manufacturer in Birmingham. However, it's not only the OEMs that have discovered the new form of robotics for themselves. First-tier suppliers also use the technology. For example, they install hexapods into coordinate measuring machines to calibrate headlamps in order to comply with the high demands on precision.

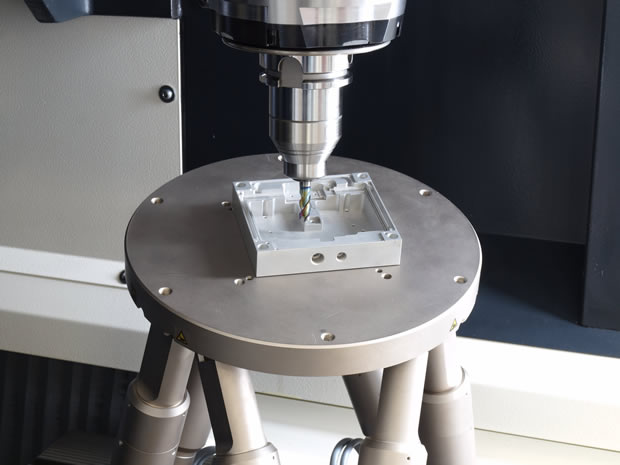

Others rely on the technology when building prototypes, high-precision processing of complex components or contactless processes such as laser welding.

The advantages of parallel kinematics

Hexapods are able to position much more accurately than the serial, stacked systems of classical robotics. Because all six axes of the hexapods act directly on the same platform, it is not possible for guiding errors to accumulate. In addition to the considerably improved precision motion, there are also further advantages such as the lower moved mass, because only the platform is moved and not the positioning systems for the other axes. This results in higher dynamics, considerably improved accuracy, as well as repeatability and travel accuracy for all motion axes. Because no cables are dragged, precision is not restricted by friction or torque. In addition, hexapods have a very compact design. For example, it simplifies the safety circuits, because the motion of the hexapod remains in a comparatively manageable workspace.

The Hexapod system as intelligent multi-axis drive

Because the controller is connected directly via fieldbus interfaces, it is possible to integrate hexapods into practically every automation system and easily synchronize clocks with other automation components. In practice, users do not need to deal with parallel kinematics and their complex transformation algorithms. A digital controller takes care of the calculations and controls the individual motors in real time. Shifting and rotation of the platform are simply commanded in Cartesian coordinates. An essential feature of the hexapods is the possibility to adapt both the position and the alignment of the reference coordinate system and the pivot point using the software.

To adapt the trajectory perfectly to the requirements of the application, it is possible to define various coordinate systems, for example, work and tool coordinate systems, which refer to the position of the workpiece or tool. All functions of the PLC standard languages can be used for controlling the hexapod systems, which means that a proprietary language is not necessary. The controller communicates with the hexapod via a standard protocol. In addition to RS232 and TCP/IP, established fieldbus protocols such as EtherCAT and PROFINET are available for this purpose. The hexapod system then behaves as an intelligent multi-axis drive on the bus, whereby it is possible to control up to two further axes in addition to the hexapod mechanics.

Software simplifies project planning

PI supplies the digital motion controllers together with an extensive software package that covers all application aspects, starting with easy start-up to the convenient control of the systems using graphical interfaces to fast and manageable integration into external programs.

A virtual controller allows development of application programs without having all of the components at hand. Simulation tools, for example, help to calculate the workspace, or objects can be integrated to avoid collisions. Dynamic libraries for development and application examples simplify implementation. A mobile app enables wireless monitoring and control.