Five steps to keep automation up and running

The high productivity and throughput achieved by implementing automated processes is a key benefit to manufacturers considering a transition from more manual approaches. Down-time due to planned or unplanned maintenance can quickly negate efficiencies if production processes are halted for too long. Every second an automated production is offline costs money, which soon adds up. In this article, TME reviews different maintenance strategies and outlines steps engineers can take to keep their automation line up and running.

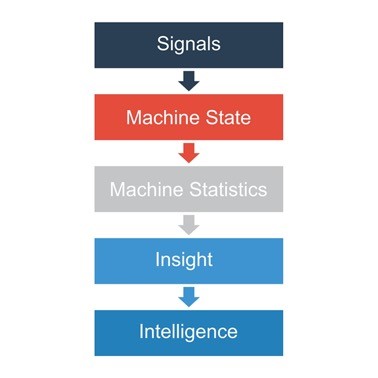

Modern automation technologies are transforming manufacturing as we know it. Industry 4.0 practices and the Industrial Internet of Things (IIoT) are gaining traction and manufacturers are starting to reap the rewards of using smart manufacturing techniques (Figure 1).

IIoT and Industry 4.0 rely on machine-to-machine communications, the cloud, and a plethora of electric automation components, sensors and actuators; all contributing to more efficient processes. With an increased number of components in a facility, there are more products than ever before that need specifying, checking and maintaining.

Figure 1 - Industry 4.0 practices are giving engineers increased intelligence so they can conduct smart predictive maintenance regimes to minimise down-time.

Step 1. Consider the maintenance strategies

Proper maintenance of automation lines is essential to maximising uptime and keeping costs low. There are typically three maintenance strategies employed in a manufacturing facility on an automation line:

Reactive

Reactive maintenance is an unplanned approach whereby machines and components are fixed as and when they break down, and the operator does not know when this might be. This is a common approach because it is seemingly the cheapest.

When the process is running smoothly, it has a minimal cost - but things don’t often run smoothly! In a large plant, the chances of a piece of equipment needing maintenance at any given point are high. And when breakage does occur it could be catastrophic and expensive to fix.

Preventative

Preventative maintenance, in contrast to reactive maintenance, is a planned approach. It includes checking equipment regularly to pre-empt any breakages, and repairing any worn parts before any costly damage is done. Conducting scheduled and routine maintenance based on the average life cycles of machinery also reduces emergency repairs and the associated labour costs.

Furthermore, it extends the life of critical equipment contributing to a reduced total cost of ownership and improved productivity. Preventive maintenance strategies are proven to have a much better return on investment compared with reactive maintenance.

Predictive

Predictive maintenance - also known as smart maintenance - is another form of planned maintenance, whereby facilities use technology to forecast when equipment will fail and maintain the equipment before any breakage occurs. Using predictive maintenance every engineer can be best prepared to do the right job at the right interval and with the right parts to minimise down-time.

The majority of predictive maintenance strategies rely on sensors, metering and software systems on machines that monitor and track the performance of automation lines. This gives engineers valuable insight into the performance of their machines, therefore enabling them to predict when a potential failure will occur, preventing unexpected breakdowns.

Properly implemented predictive maintenance regimes have several advantages. Like preventative strategies, they increase the lifecycle and uptime of the machines. They also enable engineers to manage their maintenance teams more efficiently and make associated cost savings.

Step 2. Consider back-up power units

Whether the maintenance is planned or unplanned it’s important to have back-up power in the form of Uninterruptable Power Supplies (UPS). Unexcepted power shortage, as well as voltage dips or brownouts, may lead to the loss of the contents of an HDD or damage the components, ultimately causing irreversible changes or losses.

UPS units, such as those manufactured by Eaton, are used in powering sensitive automation and control components, workstations, technological process managements centres, or for industrial data processing. They allow automation lines and devices to be shut down securely while protecting key data against sudden power failure.

Step 3. Specifying reliable equipment

Specifying reliable equipment at the outset, that is fit for purpose and the environment is crucial to maximising uptime. For example, the use of industrial computers that can process large amounts of data and are resistant to the hostile environment of industrial halls, dirt and humidity, are becoming increasingly widespread with IIoT.

These computers have cutting edge, efficient flash memories with the client’s OS of choice and other useful applications installed. A HARTING industrial computer (figure 2) with an Ethernet port and 32GB Flash memory is an ideal proposition. Its IP67 rating ensures excellent protection against dirt and humidity.

Figure 2 - HARTING’s Industrial Computer can process large amounts of data and is resistant to hostile environments

Step 4. The right tools for the job

Having the right tools for the job is also essential in minimising downtime. With any maintenance regime, engineers must have the correct equipment for the job in hand so they can carry out the maintenance operations quickly and efficiently. There are a host of tools and measuring instruments available for specific jobs.

For example, will a simple screwdriver do, or would a power tool enable maintenance personnel to do the job faster, therefore saving precious time. Ensure the maintenance kit has the essential items, as well as those more specialist items needed for the specific repair.

Figure 3 - Include basic maintenance tools in the kit to minimise down-time

Step 5. Quick access to spare parts

It is vital to make sure systems are in place to get the right spares and replacement parts quickly. This is where easy-to-use and navigate ordering processes come in. For example, TME’s Application Program Interface (API) allows engineers to optimise their shopping experience. The user-friendly tool means engineers spend less time selecting the appropriate part to fix a machine, so they can get their automation line back up and running rapidly.

TME is an official distributor of many leading brands whose electronic and passive components are enabling automation and transforming manufacturing processes, including Eaton, Panasonic, HARTING and Omron. The API provides an online catalogue and technical data for thousands of electronic parts, and in multiple languages.

Warehouse stock is updated in real time so engineers know exactly how many parts are available, and prices are given with or without individual discounts for every single product and in multiple currencies. The tool, coupled with responsive support, engineers can quickly find what they’re looking for.

Conclusion

Maintaining up-time is key for modern automation lines to remain competitive and ensure they are operating as efficiently and profitably as possible. Distributors supporting customers with high availability and rapid supply of key maintenance components and consumables can help minimise down-time. Enabling direct ordering of key components via an Application Program Interface (API) such as that offered by TME can further improve efficiencies and reduce down-time.

When coupled with smart predictive maintenance, the benefits can be even greater and efficiencies truly maximised. An effective process to minimise down-time will accelerate the return on the often-considerable capital investment to put an automated process in place in the first instance. For further information on TME and its API tool, click here.