5-axis robots: solving domestic appliance wiring challenges

Automation has transformed the manufacture of electrical and electronic products in the last few decades.

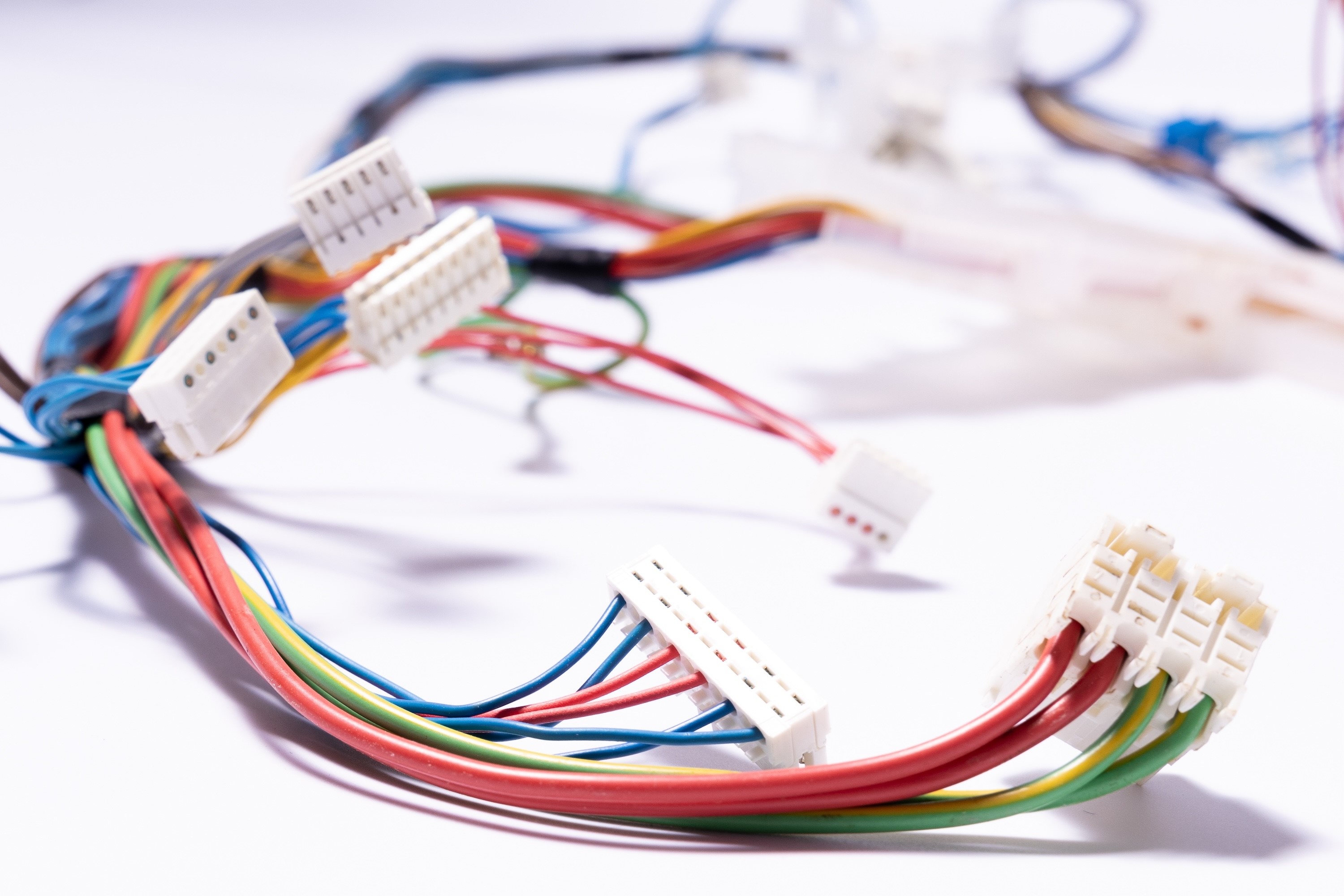

Robots assemble mechanical parts, automatically place surface mount components to populate printed circuit boards, and automatic test equipment ensures that everything works as it should. But when it comes to things like domestic appliances, one part of the manufacturing process has resisted all attempts at full automation – the wiring harness. As a result, most wiring harnesses, like the example shown in the photograph of one for a major German brand of dishwasher, are a complex tangle of wires and connectors.

Wire harnesses, like this one for a dishwasher, are the last major barrier to manufacturing automation for domestic appliances

Here, Simon Baggot, CMO, Q5D, looks at how 5-axis robots could solve critical wiring challenges for domestic appliances.

What’s wrong with manual harness manufacture?

In March 2023, the European Regional Development Fund funded and published a research study that concluded "automation in the wiring harness industry still constitutes the biggest deficiency. Despite research findings and patents, to our knowledge, none of these solutions have been implemented in the field and the state-of-the-art manufacturing process is still highly labour-intensive." This study was focused on the automotive sector, but the same challenges exist in many other industries, not least domestic appliance manufacturing.

Even though some machines are available that will bundle wires together, harnesses are still 90% put together by hand and have connectors added. They’re becoming more complex as new functionality is added to appliances to help manufacturers differentiate their products. Behind the user-interface panels of domestic appliances you’ll find power supplies (AC/DC and DC/DC), controller boards, traditional switches and touch controls, relays, visual indicators (LEDs and LCD screens), and audio devices (piezo buzzers etc.) for audible haptic feedback, indicators (such as the end of a wash), and alarm signals.

As in any manual manufacturing process, consistency is difficult to achieve, so harnesses may require 100% testing, rather than the sample testing that's often accepted as the norm in automated manufacturing. That's expensive and even then, OEMs may find they need to over-order harnesses to ensure they have sufficient stock if quality issues are encountered or if harnesses are damaged as wires are bent, twisted, and pushed during final assembly of the appliance.

Manually produced harnesses may also need to be over-specified in terms of conductor size for ruggedness and provision of insulation to prevent short circuits. Both add weight and cost to the final product.

All this means that wire harnesses are becoming more expensive to produce. Because the process is so labour-intensive, the work gets shipped out to economies where wages are lower. But with final assembly typically taking place thousands of miles away, this adds supply chain risk and complexity, and ever-rising transportation costs.

Domestic appliance wiring: reliability and safety

Statistics published by the UK government show that there were 66,753 fires in London in 2022-23. Over half were from ‘unspecified’ causes and electrical appliances other than cooking equipment and heaters – perhaps the most predictable risks – caused a further 4,206 fires. While the fire authorities don’t report the exact causes of these fires in electrical appliances, wiring is certainly one vulnerability.

In many appliances, such harnesses are subject to a wide range of temperatures, to vibration in the case of washing machines and driers, and to the potential ingress of water and other contaminants, such as detergents. All of these create the potential for reliability issues and ultimately, for damage to brand reputation.

According to the article ‘May is national electrical safety month: do you know the facts?’ by US legal firm Cullan & Cullan, “Faulty electrical equipment causes about 140,000 home and workplace fires each year. These fires claim, on average, 400 lives and cause 4,000 injuries” in the US. Around 10% of these injuries and deaths are caused by large appliances and a similar number by power tools.

How electrical function integration addresses these issues

A robot cell designed for ‘electrical function integration’, which means total or partial replacement of traditional wire harnesses, is promising significant progress towards eliminating or at least mitigating the high cost and weight, manufacturing inefficiency, and reliability problems associated with traditional wire harnesses.

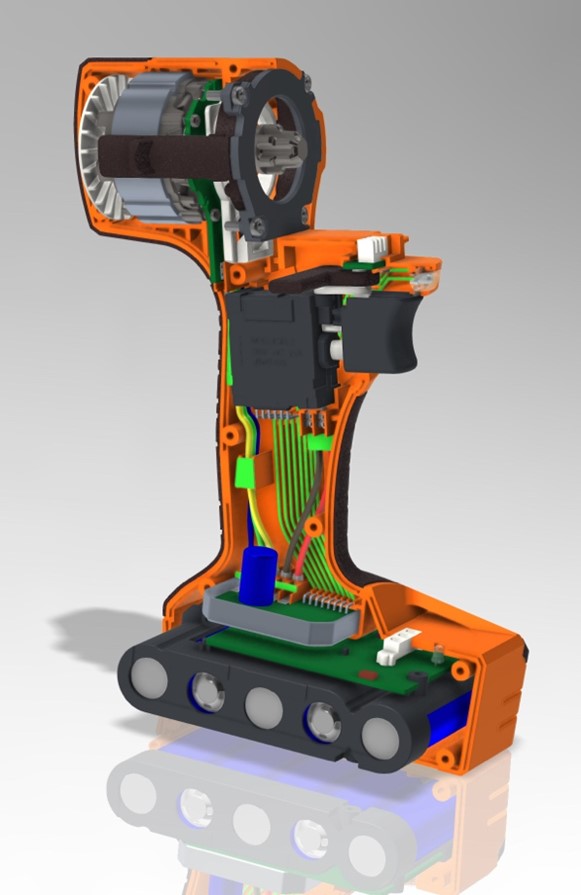

It’s a precision 5-axis robot with interchangeable tool heads, called end-effectors, that can add well-secured bare or insulated wires to system components and subassemblies, even those that have complex 3D shapes. The machine can also automatically attach electrical connectors to the wiring. The robot routes wires with conductors up to 3mm in diameter, which is approximately 13AWG. This means each conductor can carry over 20 amps, sufficient for powering motors, relays, or fans, in addition to low-level monitoring and control signals.

This 5-axis additive manufacturing cell can automatically and securely add

bare or insulated conductors into components with simple or complex 3D shapes

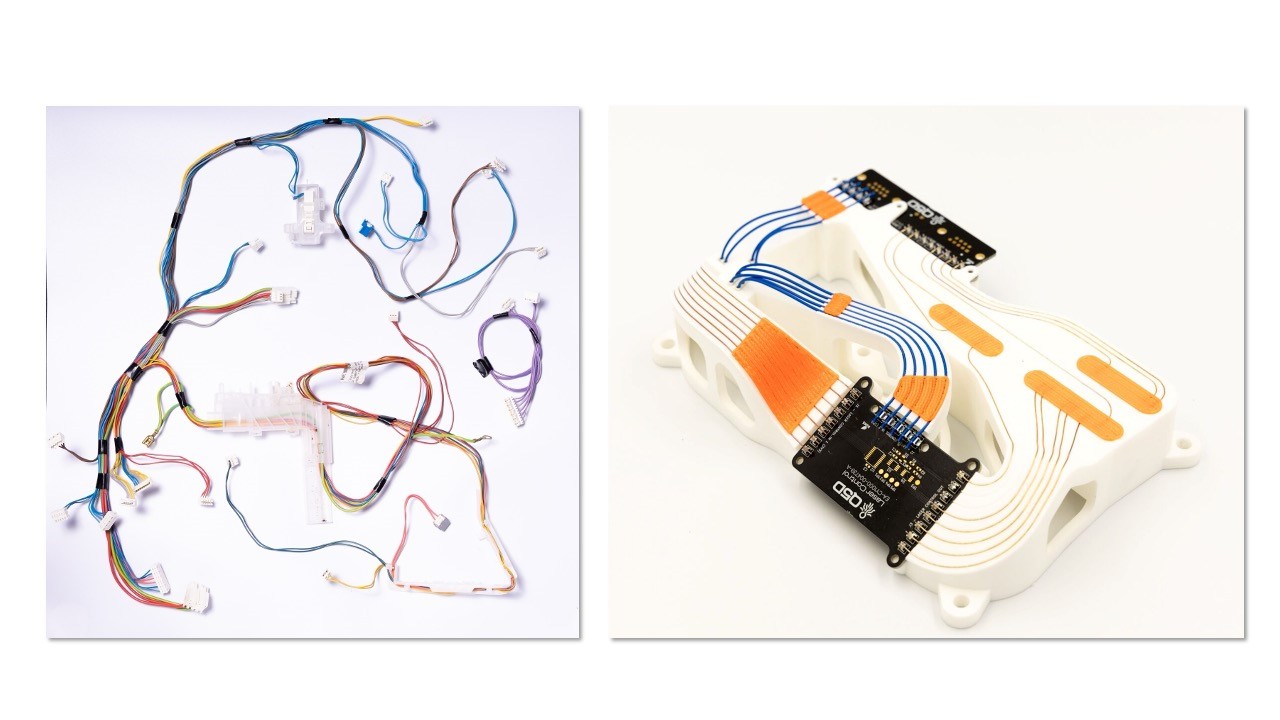

Using the robot as a stand-alone machine or integrated within a production line can significantly cut the tact time for assembling an appliance control panel, boosting productivity. The panel can be flat or curved, rigid or flexible. Because each wire is individually secured, it may not require insulation, saving cost and weight, and wires are far less prone to environmental and mechanical damage because they’re securely positioned.

The final assembly of hand tools is faster and

more reliable with automated placement of wiring

Electrical function integration is equally applicable to the manufacturing of battery-operated hand tools. Clamshell designs, where the wiring is principally in the handle of the tool, are particularly prone to wiring damage during manufacture when the two halves of the casing are brought together. With the wiring automatically affixed, this problem and the other issue described earlier, are eliminated.

The mess of wires found in traditional harnesses (left)

Sub-assemblies or components with integrated wiring lend themselves to robotic final assembly, and the reduction in the labour content means that cost-effective manufacturing can be undertaken in many more places. This can eliminate supply chain risks by co-locating the integration of electrical conductors and components with final product assembly.