Top five strategies to fortify supply chains in 2023

Developing a robust risk management strategy is vital for businesses. It enables them to tackle potential supply chain risks head-on and establish resilient plans that can withstand unforeseen challenges.

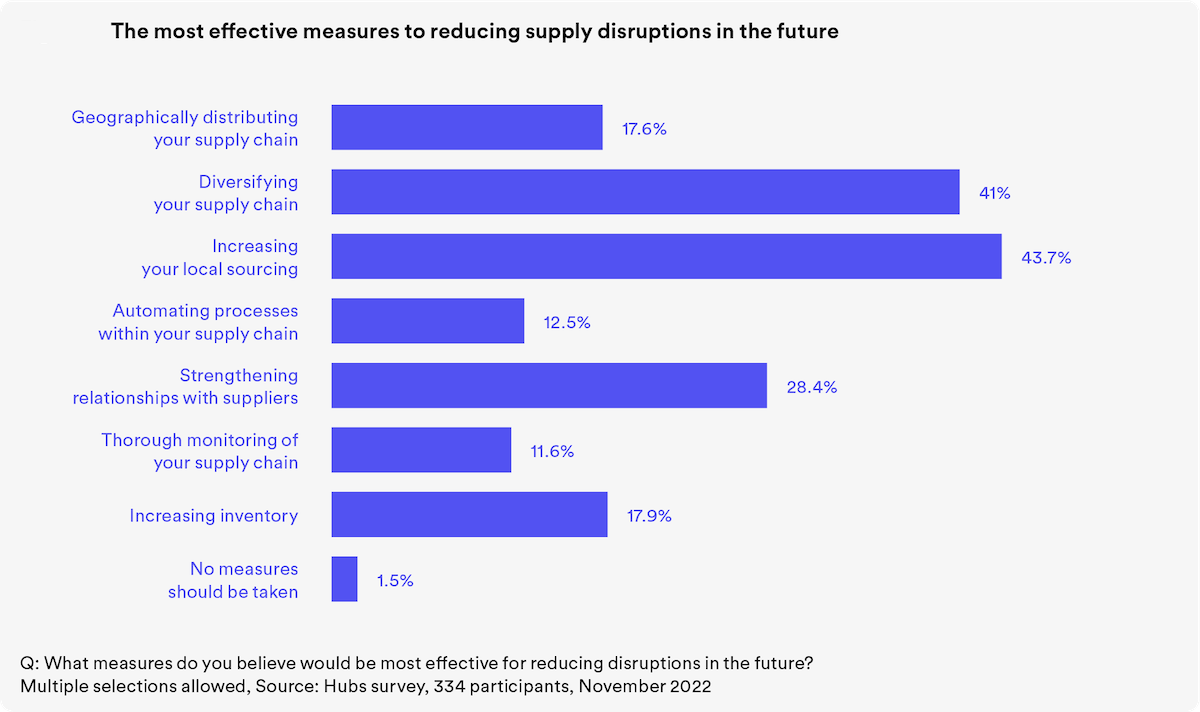

Despite the backdrop of significant supply chain disruptions in recent years, it's evident that a number of organisations are still in the process of enhancing their preparedness. A survey conducted by Hubs, involving over 300 participants, revealed that a significant 76.6% of companies encountered disruptions in 2022. This underscores the need for further efforts to fortify businesses against upcoming supply chain challenges.

This article sheds light on key elements for organisations to establish a resilient supply chain. Interestingly, these very solutions found resonance among participants in Hubs' survey.

1. Automation

With Robotic Process Automation (RPA), many repetitive manual tasks can be digitised and streamlined, reducing supply chain complexity and lessening reliance on manual labour.

Automating the Request for Quote (RFQ) and design for manufacturability (DFM) processes allows companies to provide precise quotes in a matter of seconds. Instead of relying on conventional rule-based quoting methods, the integration of machine learning algorithms enables instantaneous quotes when a customer uploads a CAD file.

Automation also helps businesses break down silos and streamline the sharing of data among supply chain links. By using industrial IoT devices such as smart shelves and sensors, data can be gathered for warehouse monitoring. This, in turn, allows suppliers to pinpoint inventory needs and identify supply chain bottlenecks and vulnerabilities.

2. Reserve inventory

Though it goes against lean manufacturing principles, building a reserve inventory can significantly improve supply chain resilience. This approach effectively creates a buffer, ensuring that if a link in the supply chain breaks, there is ample inventory to maintain operations while the link is restored. It is especially beneficial to maintain reserve inventory for critical parts and those not easily sourced from alternative suppliers.

While cost has been an obstacle to the widespread adoption of reserve inventory strategies, the rise of AI-driven cost analyses and predictions is changing the landscape. Supply chain partners will soon be able to forecast the likelihood and cost of supply chain disruptions more accurately, balancing these against the expenses of bolstering inventories.

3. Geographical diversification

Recent events have highlighted the importance of diversifying supply chains. For instance, pandemic lockdowns in China halted manufacturing at various times between 2020 and 2022, and Europe's heavy reliance on Russia for gas resulted in notable energy shortages in the first half of 2023. In our latest survey, 41% of companies indicated that diversifying their supply chain is the optimal strategy to avert future disruptions.

With a robust, distributed network of suppliers or potential suppliers, supply chains can adjust to regional disturbances and shifting geopolitics. If one geographic area is impacted, suppliers from another region can step in to bridge the gap. Establishing a sturdy and varied network of suppliers is challenging. Companies that lack internal resources to get this done, can turn to distributed manufacturing platforms like Hubs.

4. Agile internal processes

Supply chain resilience isn't just about external flexibility; internal processes play a crucial role too. Large organisations should be more receptive to agile processes, allowing team members to move swiftly and dynamically in business growth. Promoting cross-functionality and granting teams more autonomy can make internal procedures, such as product development, faster and more adaptable.

An agile approach prioritises ongoing collaboration with clients and stakeholders at every step. By continually refining based on their feedback, we ensure superior product quality, clear processes, heightened efficiency, and minimised risks, with projects under constant observation and assessment.

To put things in perspective, during the pandemic, 93% of businesses observed that their agile units outperformed their non-agile counterparts.

5. Supply chain monitoring

In the manufacturing industry, tier-one suppliers provide parts or materials directly to the original equipment manufacturer (OEM). Tier-two suppliers supply these parts or materials to tier-one suppliers, while tier-three suppliers do the same for tier-two suppliers. While many businesses focus on the first and second tiers because of their apparent importance, broadening their scope could offer added advantages.

Tier-three suppliers can have a substantial impact on the entire supply chain. Delays from these deeper-tier suppliers can ripple through and disrupt the entire supply chain. Monitoring suppliers across all levels allows businesses to detect potential issues early on, preventing larger disruptions down the road. However, the intricacies involved in tracking everything from raw materials to the finished product might explain why only 11.6% of survey respondents viewed extensive supply chain monitoring as a vital measure against disruptions. Fortunately, the emergence of specialized software tools has made supply chain monitoring more accessible.

Furthermore, companies are increasingly tapping into AI and machine learning to enhance supply chain efficiency. While a mere 13.1% of surveyed companies admitted to leveraging AI and ML, an impressive 90.9% of those who did found it extremely beneficial.

This article is a part of Hub's Supply Chain Resilience Report 2023. You can download the complete report for free by clicking here.