SmartMarker: unique identifiers for plastic products

Polysecure GmbH and plastics processor Röchling Industrial are launching an exclusive cooperation for the use of innovative marker technology in plastic products. The technology Röchling calls SmartMarker, equips Röchling plastic products with an unmistakable identifier.

Customers can easily authenticate and identify their components – offering completely new options, e.g. in counterfeit protection, the development of digital material passports and recycling cycles.

"The exclusive cooperation with Polysecure is an important step for us in the further expansion of our smart products," explains Franz Lübbers, CEO Röchling Industrial. "SmartMarker can be used to completely rethink and optimise many processes. We use the new development to further increase the efficiency of our customers and to create a competitive edge."

Polysecure GmbH has been developing innovative marker materials and detection technologies at its site in Freiburg, Germany, since 2009 and is one of the leading companies in marker technology. As part of the exclusive cooperation, Röchling Industrial can now offer almost all plastic products using marker particles by Polysecure, which are specially tailored to plastics.

SmartMarker gives customer three different applications: authentication, identification and tracer-based sorting.

Authentication

During authentication, the marker can be used to prove which company manufactured a component. To this end, the mobile BRANDPROOF pocket detector by Polysecure is used to scan any part of the component. “If the component contains the marker adapted to the individual customer, this proves the origin of the product,” explains Dr. Höfter.

Authentication: The detector is used to scan the semi-finished product or component anywhere – if marker particles are present, the scanner sends a signal. This opens up new options, such as in the protection against plagiarism and the defence against unjustified complaints

Particle fingerprint identification

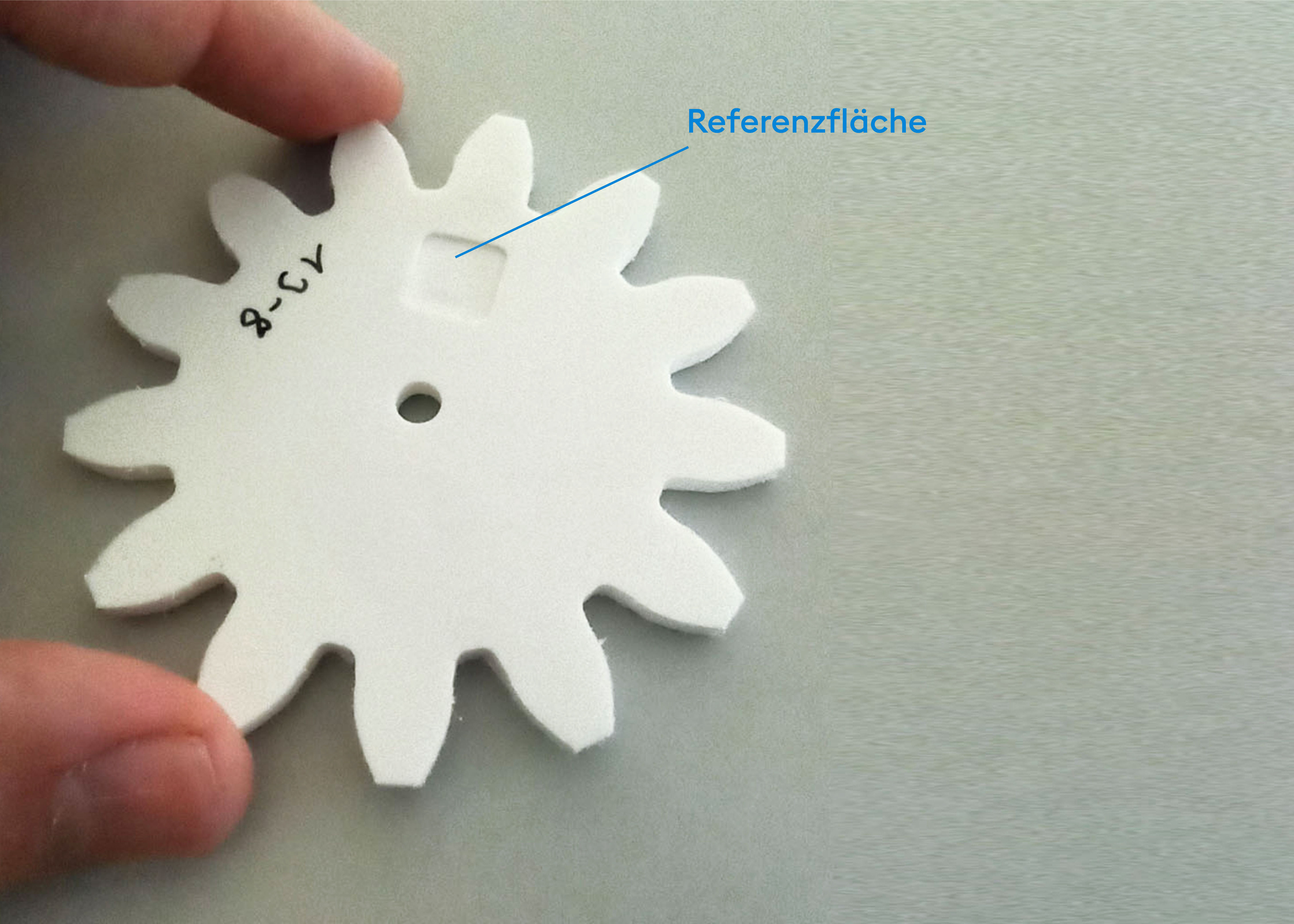

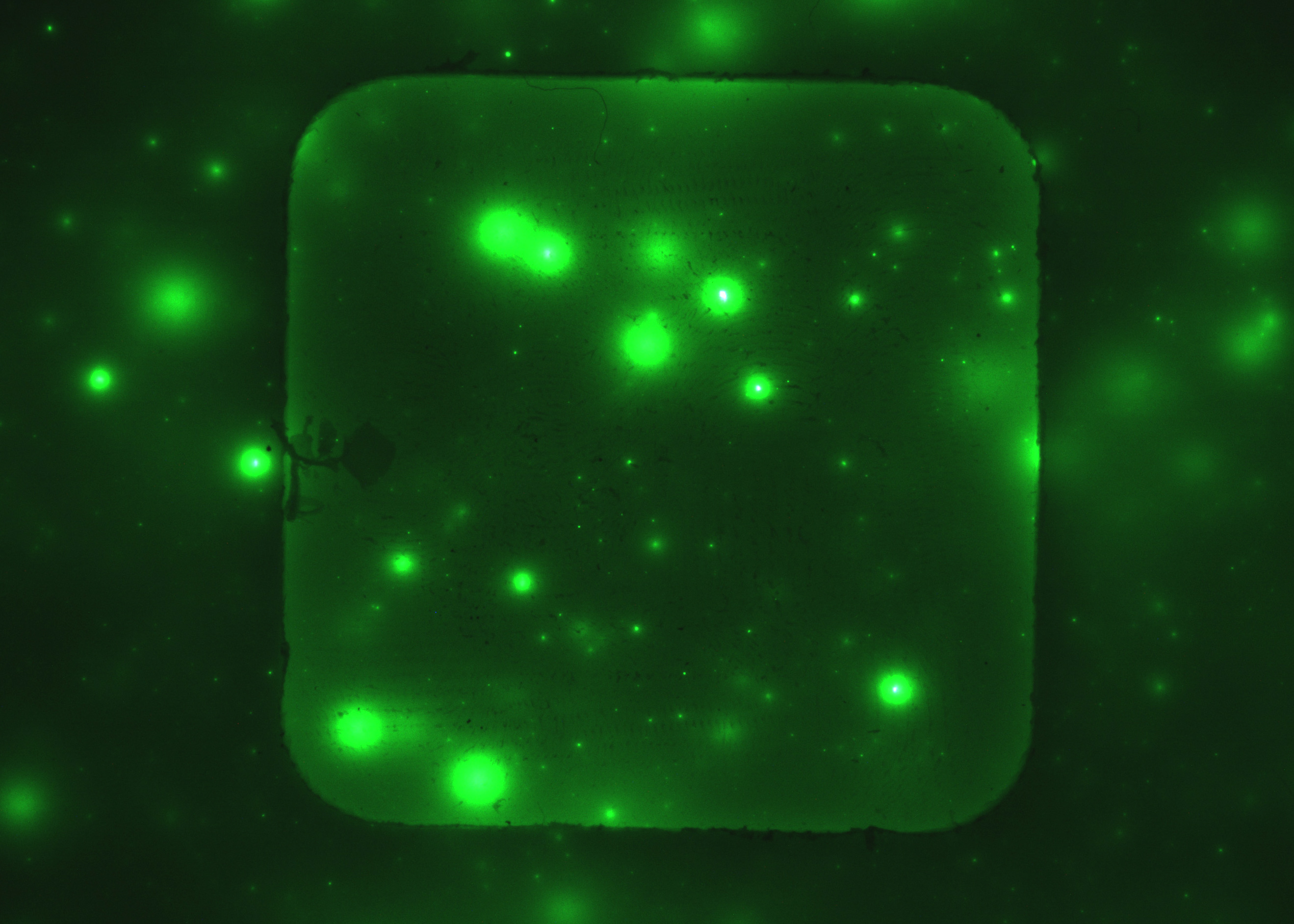

During identification, this marker can be used to determine whether a specific component is involved. For this purpose, a reference surface on the component is determined. "This reference surface contains a random, and thus individual, irreproducible particle pattern. The pattern gives the component an unmistakable particle fingerprint," explains Jochen Moesslein, Managing Director of Polysecure GmbH.

Identification: The square recess is the reference surface where the particle pattern is detected. The particle pattern of this reference surface is like a fingerprint that can be used to clearly identify the component. The fingerprint can be digitised and digital material passports can be created.

Tracer-based sorting

Tracer-based sorting (TBS) is a sorting technology developed by Polysecure that detects markers in plastics. This opens up entirely new options in the development of recycling cycles involving clients. Tracer-based sorting can be used to sort plastic waste for recycling efficiently and reliably. This creates transparency and dedicated take-back cycles can be established with customers,” explains Dr. Höfter.

Authentication, identification and tracer-based sorting offer many new application options for customers.

Better protection against counterfeits or complaints

Authentication and identification can be used to optimise counterfeit protection and the prevention of unjustified complaints, for instance. "Customers can use marker technology to mark their original parts and thus distinguish them later from unmarked ones. In this way they can protect against counterfeits and unjustified complaints," says Dr Höfter.

Creation of product passes

SmartMarker can also be used to create digital product passports. "The particle fingerprint can be digitised and stored in databases. Our customers can save further product and quality-relevant information for their fingerprint – such as material properties, customer information and batch numbers. This is how SmartMarker is used to create a digital product passport," explains Dr Höfter.

Cooperation: Philip Rosenbaum, Röchling Industrial and Jochen Moesslein, Managing Director of Polysecure GmbH