How to address the challenge of long lead times

For original equipment manufacturers (OEMs), securing appropriate levels of inventory for long lead time components and sub-assemblies is a costly, time-consuming and perennial challenge. Increasingly OEMs are outsourcing, but choosing the right supply partner can make all the difference to companies looking to boost their competitiveness in a rapidly changing market. Paul van der Tang, Purchasing Director of Offshore Electronics explains.

Extended lead times for components and sub-assemblies can cripple the business model for electronics manufacturers. Whether its new product development or securing existing supply chains, reducing and accurately forecasting lead times is a critical element of any manufacturing operation. It is also one area which is frequently neglected by businesses.

The industry is littered with cautionary tales of manufacturing production lines coming to a grinding halt for want of a ‘cost of a nickel’ component. However, an effective and robust approach to lead time reduction does represent an opportunity to deliver significant commercial benefits for OEMs.

Outsourcing: the growing need for agility

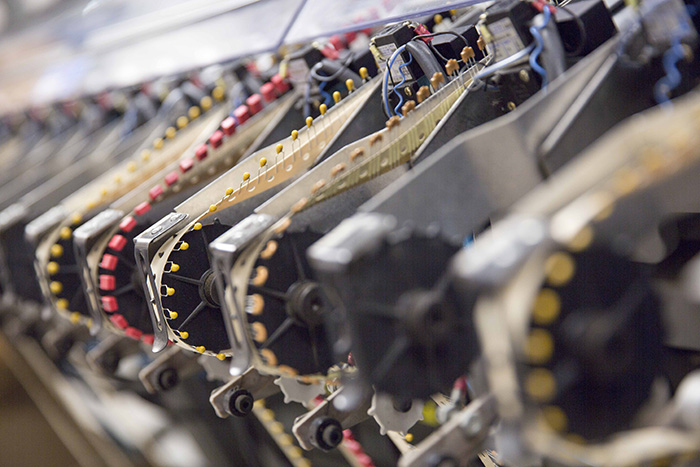

Manufacturing businesses are expected to prioritise stability, reliability and security of supply. However, in today’s competitive landscape there is a growing need for agility. Speed to market is a vital factor in securing market share in commercial markets. As companies increasingly pursue the benefits of Industry 4.0 and the Industrial Internet of Things (IIoT), technologies and consumer demands are evolving rapidly. Being first to market a new product is generally considered to be worth around a third of the available market share, yet the bulk of new products miss launch dates.

For both new products and existing production, long lead times, lack of suitable inventory, delays in shipping and other supply chain failures are a negative influence on manufacturing businesses far too frequently. This is particularly true with low value production components.

The inevitable result is production line down-time and delayed product shipments. This makes responding to market changes increasingly challenging and there is a consequent loss of market share. There is less time to respond to quality control issues and the opportunities for volume purchasing and building economies of scale diminish.

In addition, there are significant reputational risks, as well as the potential for compensation payments for delays in product delivery. It’s no exaggeration to say that managing production lead time, including all the manufacturing, sub-assembly and assembly processes required to build and ship a product, is at the heart of successful manufacturing. Nonetheless, the lack of a truly considered focus on addressing long lead times continues to reduce the margins, profits and competitiveness of many OEMs today.

Adopting a low-cost, low inventory strategy

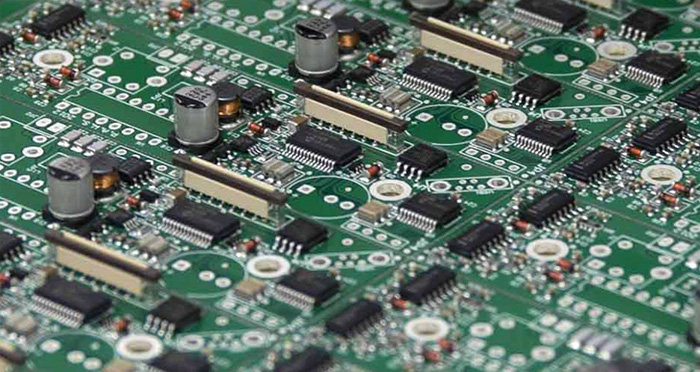

In addressing the known business risks associated with long lead time electronic components, PCBs and sub-assemblies, many manufacturers turn to a strategy of inventory building. Though understandable, this is a mistake. Compensating for potential supply chain and market variance to reduce the risk of production schedule interruptions, manufacturers are grossly inflating costs, generating waste and tying down cash flow.

Inventory requires capacity for storage and people to manage and quantify the stock, as well as execute any transport logistics. Increased inventory also represents a number of business risks. If the market changes, in-stock components may become effectively obsolete or not appropriate, potentially leaving manufacturers holding a lot of expensive scrap.

Above: As companies increasingly pursue the benefits of Industry 4.0 and the Industrial Internet of Things (IIoT), technologies and consumer demands are evolving rapidly

Even vendor-held inventory can come with business exposure given common clauses requiring purchasers to buy the vendor’s materials, even if the business has potentially changed in the meantime. Excess inventory can also hide waste, supply chain and quality issues. It can cloak organisational, scheduling and forecasting challenges and means that manufacturers lose the potential benefits offered by a lean manufacturing strategy.

While excess stock addresses the more immediate fear of halting production due to lack of inventory, particularly in the case of long lead time elements, it actually masks the root cause of the problem. Long lead times make it difficult to accurately forecast inventory requirements to meet future demand.

However, while some manufacturers simply accept these perceived consequences of long lead time components as a part of normal business practice, there are alternative approaches.

Cutting delivery lead times

One simple measure to address long lead time supply chain issues is to use domestic suppliers. For example, components coming from the Far East might take several weeks to journey to Europe aboard a freight vessel. Selecting a local manufacturing partner means shorter, less complex delivery routes and removes a substantial part of this issue at a stroke.

While local suppliers may not be able to deliver assemblies any more quickly than one based overseas, the risk of delays and the potential for disruption is considerably lower. There are other potential benefits too. For instance, domestic suppliers typically use approved components and processes suitable for local markets. This eases accreditation and product compliance requirements and increases credibility as well as market acceptance.

Good customer support and effective communications are also key to address long lead time issues. Building up a rapport with suppliers through good communications can yield substantial benefits. Sharing sales-derived data with suppliers, for example, can help them in anticipating orders and manage resupply more effectively to minimise lead times. Domestic suppliers also have none of the differing time zone or language barriers that can complicate communications with overseas suppliers.

Rather than building excess inventory, another strategy to consider in addressing long lead times is to increase the order frequency and place smaller orders. Though larger orders are typically associated with lower prices, the additional inventory management costs and business risks may more than eliminate any benefits accruing from lower component unit pricing.

Reducing supply chain complexity is another worthwhile endeavour. For example, OEMs may consolidate their suppliers to avoid the complexity of coordinating multiple vendors and purchase orders. Condensing the supply chain by using standard components where possible, or streamlining processes and information flows, can cut waste and overall cycle times.

Relatively straight forward inventory management techniques, such as the two-bin Kanban system, or implementing a management software programme, are also beneficial. They can help create efficiencies through more accurate forecasting, planning and scheduling. Introducing measures to reduce cycle times, in particular by reviewing processes such as production line set ups and changes, can also cut overall lead times.

The role of external partners in outsourcing

More sophisticated approaches are seeing some manufacturers build up full supply chains internally. Increasingly though, OEMs are focusing on supplier development and using trusted external contract suppliers and specialised Contract Electronics Manufacturing (CEM) companies.

Given that manufacturers’ core competencies are typically centred on design and production, managing a large volume of low-cost small components generally falls beyond their scope of expertise. As a result, building strong partnerships with reputable suppliers is often the most effective and efficient way to reduce lead times. Outsourcing as much as possible of the non-core competencies, such as component and sub-assembly supply, allows OEMs to escape much of the headache of inventory management.

When working with a contract supply partner, commonly used approaches are vendor managed inventory (VMI) or vendor-owned inventory (VOI) programmes. Such supply agreements substantially reduce the need for physical space for inventory while eliminating production down-time risks arising from inventory management and supply chain failures.

Above: In addressing the known business risks associated with long lead time electronic components, PCBs and sub-assemblies, many manufacturers turn to a strategy of inventory building

Though the idea of transferring responsibility for processes that may have been managed internally for decades can be daunting, utilising supplier core competencies centred on procurement, logistics and inventory management provides OEMs with a reliable and lean replenishment process.

Whilst keeping inventory at low levels, working with select contract electronics manufacturers can also deliver economies of scale in terms of component purchasing. Contracted to multiple customers, larger contract manufacturers can represent significant bulk purchasing power. This is particularly significant for small and medium enterprises which might not otherwise have built sufficient volume to curb component costs.

In addition, top tier domestic suppliers can also offer expertise on other factors that support OEM competitiveness, such as designing for improved manufacturing and opportunities for standardisation. Collaborating with the product designers, specialist supply companies are able to determine if appropriate modifications are possible without compromising on the performance or quality of the final product. This saves time in engineering and production as well as reduces costs and can further address potential lead time issues through selecting alternative components. With a good supply partner, performance and quality can be improved while lead times are reduced.

Choosing the right outsourcing partner

To realise the benefits of developing strategic contract supplier relationships, OEMs must carefully consider a number of factors in their partner selection. Contract manufacturers with inventory management experience and established access to a full-scope supply chain is an obvious early choice. With experience in both design and manufacturing, the right contract manufacturer may also find opportunities for standardised components, cost reduction and improved assembly efficiency. Some contract manufacturers have electrical engineering design teams able to provide feedback on PCB and circuit designs for further optimisation and to improve their quality.

Maintaining communications from the very start of the process further supports the management of long-lead time components. For example, including supply partners in early design reviews and with likely materials requirements allows them to secure the necessary inventory in a timely way or recommend alternative components.

There are significant opportunities for OEMs to reduce potentially crippling lead times. Taking action to fundamentally address the key issues coincides with a host of residual benefits. Effectively managing lead times is a primary factor in achieving lean manufacturing processes. Reducing lead times also allows products to be built and delivered more efficiently, improving cash flow with less waste, reduced labour requirements and lower inventory levels.

Furthermore, reducing lead times helps OEMs secure against reputational risk by improving reliability and avoiding delivery delays. This in turn can bolster client retention.

With the right expertise, stable and high-quality strategic suppliers can create effective supply chain solutions, so that long lead times don’t impact on OEM core business models. Instead of a challenge, robust supply chain management can deliver a key competitive advantage.