Securing IoT solutions with Winbond Flash Memory in Industry 4.0

The fourth industrial revolution is being fueled by data and machine learning, and is defined by the digital transformation of factories through the convergence of Information Technology (IT) and Operational Technology (OT) at scale. Dubbed ‘Industry 4.0’, it has already empowered many factories to become 'smarter' through real time monitoring, AI-driven decision making, autonomous manufacturing, and even predicting market demand.

The automation and data exchange in manufacturing technologies provides new opportunities for manufacturers eager to transform and upgrade their production process in order to cut costs, improve outcomes, and deliver modern customer experiences. According to MarketsandMarkets, the Industry 4.0 market is projected to reach $156.6bn by 2024, from $71.7bn in 2019, with a CAGR of 16.9%.

Industry 4.0 Implementation Considerations

Implementing Industry 4.0 transforms manufacturing by involving and integrating components like big data, cloud computing, AI processes, wireless connectivity, IoT-enabled industrial assets, and more. To create a ‘smart factory’, there are a number of key factors to be considered in planning the transformation of the manufacturing process - let’s take a look at the elements below for example.

Cloud-based Analytics:

Industry 4.0 equipment is notable for its extensive generation and use of ‘big data’, always-on power requirements, and pervasive connectivity to the internet. As LPWANs (Low-Power Wide-Area Networks) proliferate in factories, warehouses, and industrial campuses, the supply chain will increasingly be able to share and monitor real-time data about machines, products, inventory, and other assets with sophisticated analytics software in the cloud.

Low Power IoT Components:

Underpinning this explosion of digitisation is the massively increased deployment of sensing and other IoT devices, such as RFID smart tags which can be read wirelessly. These devices, operating from a battery power supply or even from harvested energy, will often require an ultra-low power memory component for storing logged data.

Higher Code Storage Capacity:

New implementations of these sophisticated applications will run on larger code bases, far greater than is typical for today’s industrial appliances. This will bring pressure on industrial system designers to find code storage solutions which meet the hugely increased capacity requirement without increasing the bill-of-materials cost or board footprint.

Connectivity and Security:

Lastly, a common theme in all types of Industry 4.0 equipment is connectivity - this brings the inherent risk of compromised security. By guaranteeing device authenticity in Industry 4.0 equipment that stores code and data, secure non-volatile memory chips are a viable hardware barrier to block intrusions into sensitive industrial networks.

Security Risks in Industry 4.0

As Industry 4.0 concepts and components have been widely adopted and applied, the manufacturing industry has become an appealing target for attackers. The integrated systems could be seen by attackers as an opportunity to easily move across a manufacturing network, jumping across IT (Information Technology) and OT (Operation Technology) systems for their malicious activities.

The equipment utilised in the always-on, always connected implementations of Industry 4.0 are, unless properly secured, exposed to risks from malicious hackers who could access networks and compromise privacy or steal data. According to research released by Trend Micro in May 2020, the systems and facilities that may be used for these malicious activities include manufacturing execution systems (MES), human-machine interfaces (HMI), and customisable IIoT devices. These are potentially weak devices in terms of the security chain. Once these systems are attacked and compromised, it may cause produced product damage, equipment failure, or even product defects.

There are many measures available for designers to combat security risks. One of the most important measures is hardware authentication, which guarantees that only authorised devices share data over a network.

Winbond Secured Flash Solutions

(source: Winbond)

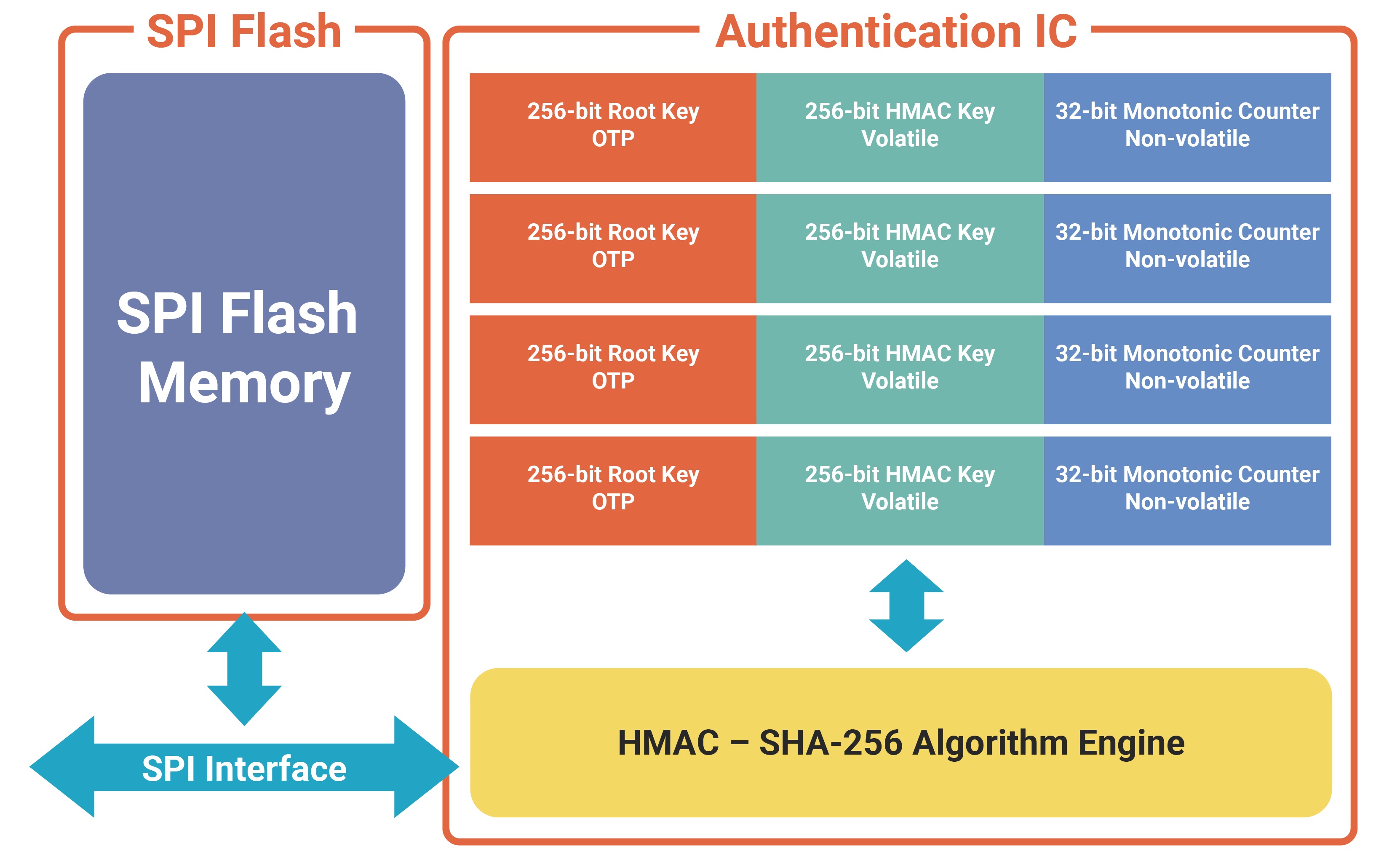

To provide hardware authentication for critical software such as boot code, Winbond has introduced the W74M family of Authentication Flash Memory solutions. Each W74M part incorporates an SPI (Serial Peripheral Interface) Flash memory with a security IC (Integrated Circuit) in a multi-chip module.

The device is secured with a standard HMAC-SHA-256 crypto accelerator and four monotonic Flash counters which are HMAC-signed by individual secret keys. Systems utilising each Monotonic Flash Counter can verify the integrity and authenticity of the counter values as well as add a timestamp to the message/information transmitted as well as provide resistance to replay attacks.

(source: Winbond)

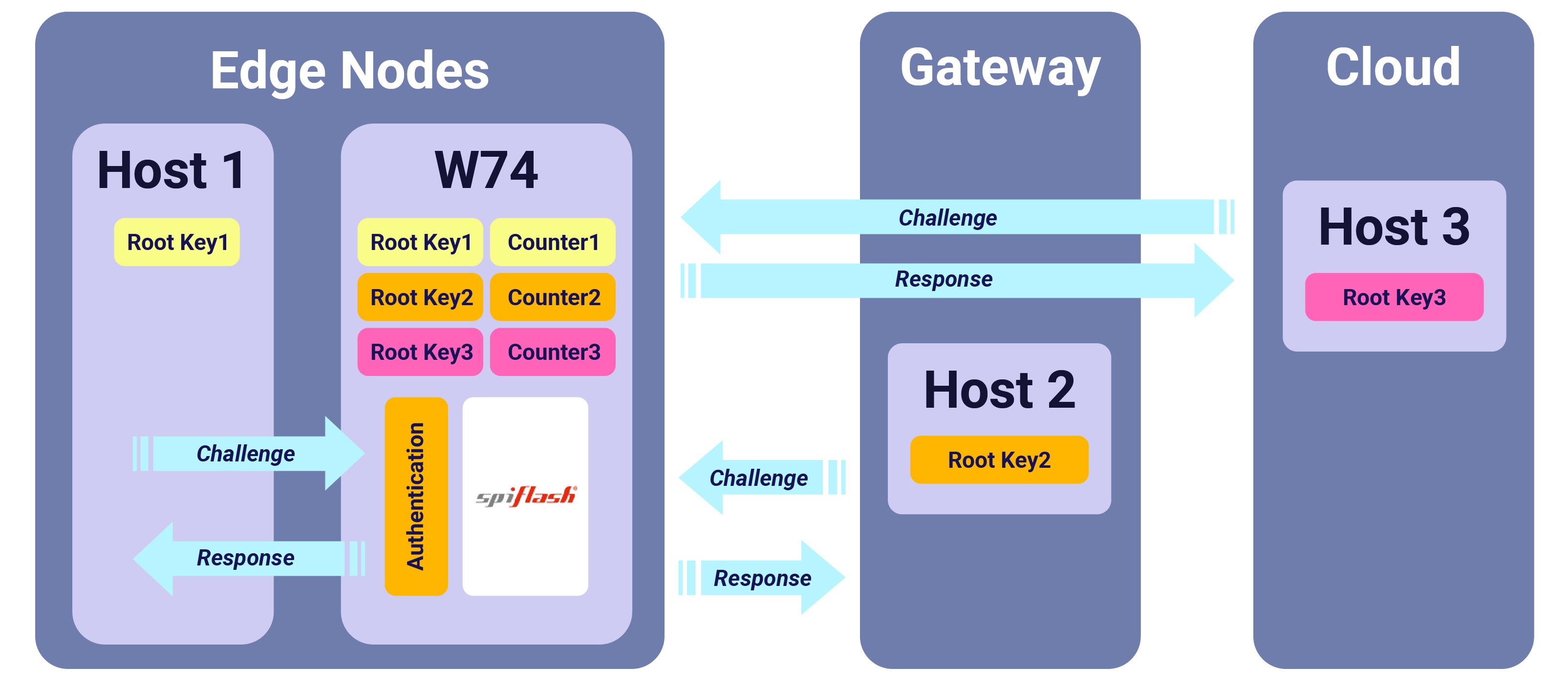

W74M products enable system designers to strengthen code/data storage as well as deliver increased security with multi-layered authenticity for emerging IoT devices on the edge or other places outside of the cloud. These security products also provide enhanced security to gateways, sensors, doorbells, cameras and other similar devices.

(source: Winbond)

Access to the code or data stored in the Authentication Flash memory is protected by a secure key, which is unique to each manufactured unit. In the event of tampering or intrusion into the network, the boot code or data stored on an Authentication Flash will remain secure from attempts to steal, modify or impair it.

In addition to industry IoT, W74M family of Authentication Flash Memory solutions are also suitable to protect the data stored in mobile accessories, home automation devices, and smart phones to name a few.

How to get the most of the Industry 4.0 era, manufacturers should start by thinking about building the secure IoT environment from the both perspectives of software and hardware. With the reliable secured memory solutions, manufacturers will be able to securely embrace the digital transformation and to optimise their productive process, improve manufacturing efficiency, and have greater produced products.

Winbond - The Worldwide Leader in Total Memory Solutions

Winbond provides customer-driven memory solutions backed by expertise in product design, R&D, manufacturing, and sales services. Their solutions have been widely applied to diverse industries and applications, such as wearables and hearables, wireless LANs, automotive, servers, 5G, etc. Winbond’s product portfolio, consisting of Specialty DRAM, Mobile DRAM, and Code Storage Flash, is widely used by tier-1 customers in communication, consumer electronics, automotive and industrial, and computer peripheral markets.

The advantage of technological autonomy and prudent capacity strategy enables Winbond to build a highly flexible production system and create synergy among product lines.

TECHDesign - The Winbond Online Direct Store

TECHDesign is the digital ecommerce platform to bring the electronics supply chain online and offer a convenient way for clients to shop for electronic components they need directly from manufacturers. In addition to Winbond memory, TECHDesign’s comprehensive product offering includes microcontrollers, passive components, wireless communication modules/SoC, and power semiconductor devices, to name a few.

To buy Winbond memory or find more detailed information, please visit TECHDesign.com.