Bringing the test lab home with you

While many employees have had to work from home due to the coronavirus pandemic, this is rarely an option for engineers who need constant access to test equipment. However, as Rohde & Schwarz explain, you can bring the test lab home.

Remote control of test equipment has been standard practice in labs and system houses for many decades. Nowadays even low-cost devices have the necessary interfaces, at least as options. Top-end devices often have built-in web servers, allowing them to be operated remotely from any browser.

All that is needed is the IP address, and the device must be accessible online. For remote unattended measurement stations with a static setup, remote access and operation is already common practice. In all cases, it is important to have effective access protection with authentication mechanisms.

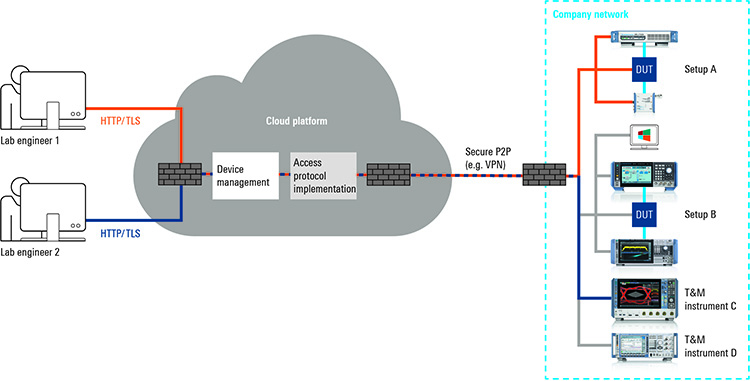

Above: Figure 1. A T&M equipment cloud like the one Rohde & Schwarz operates for its own purposes and that could also be set up for customers

This is not a problem in a protected lab environment, where remote control capability is often used for convenience to avoid having to constantly go back and forth between the workplace and a test lab located elsewhere. What these scenarios have in common is that they are one-off special solutions that have to be reconfigured for each application. For those who want to take a broader approach to remote control of test equipment and make it a workable standard practice, a cloud-based solution is an obvious approach.

Collaborative measurement via the cloud

Everything as a service (EaaS) is the latest trend, and it is becoming more and more popular. Users of such services, most of which are based on cloud technology, save on capital expenditures because they do not have to maintain the underlying infrastructure and only pay for the services they actually use. In addition, these services are usually highly scalable, so users can count on the required capacity being available. A prerequisite for moving a service to the cloud is that it can be virtualised. At a virtual sales counter, the user simply books a service based on type, time, scope and quality. The cloud management system allocates the necessary resources.

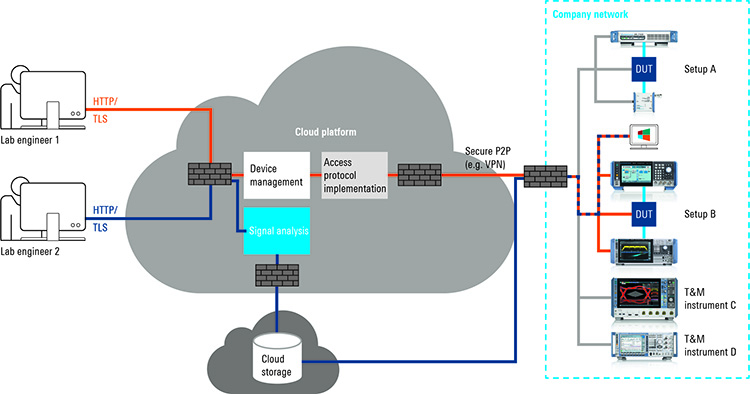

Above: Figure 2. Adding a data analysis path to the setup in Figure 1, Measurement data collection at the instrument location and data analysis can be decoupled and performed by different persons

Such systems can also be set up on a smaller scale for test and measurement services. These differ from typical software as a service (SaaS) solutions with regard to the type of service and the resources. A company that wants to virtually pool all or a part of its T&M equipment to make it accessible company-wide from any location only has a limited number of each type of T&M instrument in its portfolio, and unlike a server, each instrument can only be used for one measurement task at a time. Scalability is not the main consideration here. However, collaboration and remote access are increasingly important and necessary – now more than ever.

Figure 1 shows the basic structure of a T&M equipment cloud. The cloud operator has reserved a set of instruments for cloud access and formed instrument groups for frequently used setups. Virtual operation of a T&M cloud is not fully possible because most instruments need a physically connected device under test (DUT). A helpful soul on-site has to provide the connection. In many cases, the cloud users will do this step themselves whenever possible, and then carry out their analyses remotely. In extreme cases, instruments and users are in different countries or even different continents, for example in a collaborative development project. Then each user will have to find a workable solution based on the situation and task.

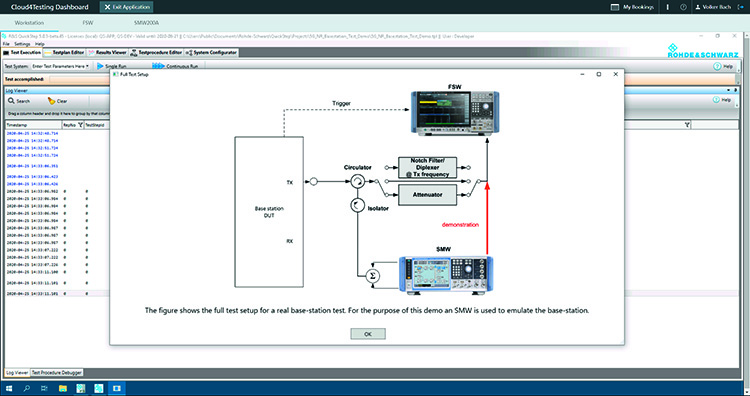

Above: Figure 3. Rohde & Schwarz also uses its own T&M equipment cloud for demos and training

Access is possible via any web browser. TLS encryption on the web ensures a secure connection with the cloud. Typical for the cloud, the system includes a device management service that prevents multiple use of devices and enables times to be reserved. You can book individual devices or preconfigured device groups, which are managed via a local control computer that is also used to exchange data with the setup, e.g. to upload waveforms or script files. With devices that support access via the RDP or VNC remote desktop protocols, an access protocol translation service sets up the connection. Then the data stream flows from the cloud platform through a dedicated point-to-point communications channel, for instance a secure VPN tunnel, to the remotely controlled hardware.

In order to extend the possibilities for measurements based on the division of labour, a cloud storage component can be added to the Figure 1 setup (Figure 2). This also makes it possible to separate the collection and analysis of measurement data. For example, one engineer can execute the measurements and send the data to cloud storage, while a second engineer performs the software-based analysis at a convenient time from any location.

R&SCloud4Testing

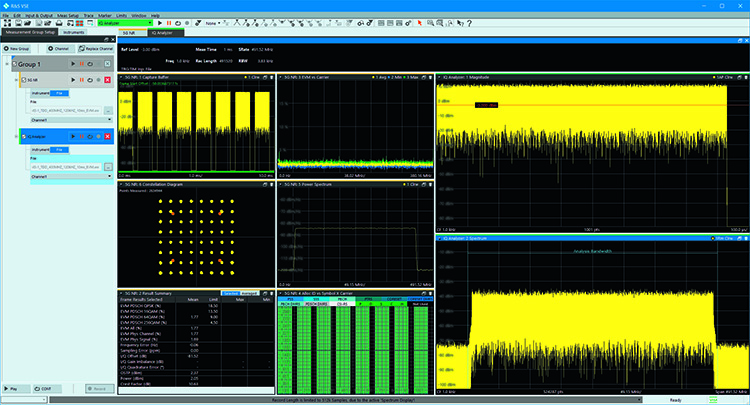

This use case – cloud-based measurement data analysis – is supported by the new R&SCloud4Testing SaaS that is available to the public as a paid service at www.rohde-schwarz.com/cloud4testing (all products are also available as free trials). The service currently offers analysis packages for various mobile communications standards, as well as general transient and pulse analysis packages (Figures 3 and 4). Other packages are in preparation.

Above: Figure 4. Various packages for mobile network analysis, pulse analysis and general signal analysis can be accessed on the R&SCloud4Testing SaaS

The ‘large’ cloud solution for instrument access is worth considering for companies that want to make some or all of their T&M equipment conveniently available online for collaborative work, customer demos, training courses, better resource utilisation and other reasons. As a reliable partner, Rohde & Schwarz can assist in the custom implementation of this kind of cloud if desired, with connection to a cloud storage system as shown in Figure 2. Larger versions of thiese images can be viewed online - clik headline.