Configurability in power systems - is it an easy choice?

For most product designs, using standard power systems is considered the most cost-efficient option compared to a configurable part. However, the power supply specification must be given careful deliberation. David Cadars, Technical Development Manager Power / EMech at TTI Europe explains.

Design teams need flexibility and although they may want to use standard products, the projects they are working on usually require components that are anything but standard. In terms of power rating, size, monitoring and control features and even safety compliance, most power supply standard offerings can fall short and impact the overall design. A flexible, modular power supply enables the designer to quickly respond to any changes and specify exact power ratings that are not supported in standard parts.

Once the correct power range is defined, the design team can implement a board layout with the correct power supply footprint and connections that stay the same throughout the lifecycle of the product. Any changes or additions to output voltage can be implemented through the selection of the right modules and with programmable power supplies, through software changes to the digital control loop. With the footprint of the base unit staying the same, a power module can be replaced instantly without any NRE or tooling costs.

Above: Excelsys CoolX fanless configurable power supply for mission critical applications

Fixed specification, standard or ‘off-the-shelf’ power supplies cannot be changed mid-design so easily, requiring a new board layout and incurring NRE fees – adding to the overall cost and significant delays in time to market. For many products that are designed in medical, industrial or military applications, the benefits of a configurable power supply are critical to delivering a successful project on time. Designers are continually under pressure to reduce development time, and the integration of the power supply must be as seamless as possible, with any issues being ironed out without causing any delay to the project. Configurable power supplies give the flexibility of non-standard voltage outputs in one unit without excessive customisation costs.

It is often argued that a standard system boasts economies of scale – one size fits many for multiple customers. If this were the case, then when it comes to power supplies, a manufacturer must produce enough standard products to meet the varying customer requirements, so in comparison, a configurable unit is a win for both the customer and the manufacturer. Choosing the right power supply is therefore a very important step in the process, and there are several solutions available.

What’s so good about configurable?

A configurable power supply unit is a base unit and a power factor correction stage with mains filtering and plug-in modules that allow for individual output isolation and regulation. This makes specification changes mid-way through the design process easy to implement by swapping a module or adjusting the voltage of a single output without impacting other outputs. Most manufacturers produce base units that allow the configurable supply to meet worst-case performance and safety specifications, making them suitable for critical applications such as medical devices.

So, choosing the right power supply unit at the outset is a very important step in the design process. And with several specialist solutions available, it is always best to seek advice when making the choice. One such specialist in configurable power systems is Artesyn - acquired by Advanced Energy late last year – and its power supply portfolio provides configurable solutions for a range of specialist applications such as semiconductor test systems, medical imaging and diagnostics, industrial automation and robotics, as well as test and measurement.

It covers a low power range up to 1,800W and a high-power series up to 24KW. The iHP high power configurable range is modular with up to eight outputs and provides accuracy, resolution and stability as either a programmable voltage or current source. The modules can be connected in series or parallel and will achieve accurate voltage and current sharing. Artesyn has already secured medical and industrial safety approvals and compliance for this range of products and the analogue or digital interface supports standard communications protocols including CANbus, Ethernet and RS485.

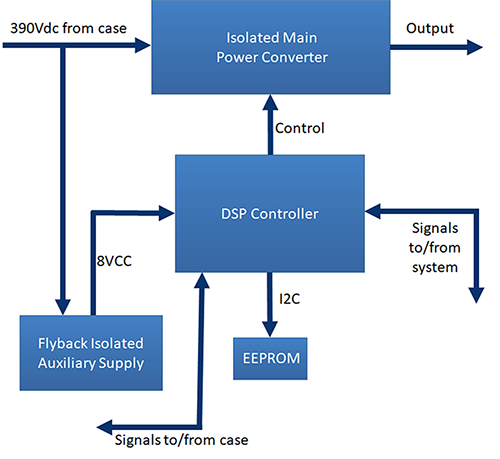

Above: Block diagram of a typical DSP-controlled output module in a configurable power supply (source Artesyn)

The lower power range µMP family from Artesyn also has medical safety approvals and provides up to 12 outputs, smart fan control and monitoring of temperature, fan speed, output voltage and output current. This product range offers a competitive alternative to non-configurable power supplies.

However, with over three million combinations enabled by the complete range of modular power supplies by Artesyn alone, not counting other suppliers, it is not always obvious which part is right for a particular design. This is where the expertise of the distributor is critical in navigating what the best, most cost-effective solution will be. Typically, designers know of the challenges that a mid-design specification change can cause but need to complete the project on time and within budget.

Specialist distributors such as TTI not only supply immediate availability of the Artesyn parts from stock, but have a team of dedicated engineers who understand the design challenges and can evaluate all the available options to a customer, offering practical advice on which power supply is right for each project. This is also a critical consideration at the beginning of the design process.

Fanless power supplies – quiet but powerful

Another challenge and something to be considered when selecting the right power supply is that many applications require fanless power supplies. The fan in a power supply unit is often the weak point in its design, often too noisy, particularly in medical or scientific applications where noise or vibration can be damaging. Excelsys - again acquired by Advanced Energy - produces a fanless 1,000W power supply with natural convection cooling which makes the power supply more reliable and can in some cases extend the system lifecycle. Cooling takes place by the natural flow of air (passive natural convection) or using methods to transfer the heat through direct contact with a cooler component (passive conduction). When applied to power supplies, passive natural convection usually involves an open-air rack where the natural movement of air across electronic components sufficiently eliminates excess heat. Passive conduction brings components such as heat sinks or cold plates into contact with the hot surface, conducting heat through the colder material and away from the power supply.

There are so many considerations to the choice of a configurable power supply, with cost being of course one of the most important. However, the flexibility that they offer can sometimes provide the overarching reasoning, a wider range of features can attract different market segments and variations of a product can be made without the additional cost of a new board layout or tooling to take into account a change in power specification.