Shrinking motor drive systems accelerate electrification

If the drive of the automotive industry towards electrification was ever in doubt, a further nail in the coffin of the internal combustion engine (ICE) was hammered home recently with the announcement from Jaguar Land Rover (JLR) that the company will be 100% electric by 2025. Kannan Soundarapandian, Business Unit Manager, Motor Drives, Texas Instruments (TI), looks at how motor drive systems are propelling this paradigm shift.

JLR has also announced the target to become a net-zero-carbon business by 2039, including a major shift to electrification. And, by the end of the decade, every Jaguar and Land Rover model will be offered with an electric-only version.

As the UK Government wants to outlaw the sale of wholly petrol and diesel cars from 2030, this a trend that is likely to increase and as a consequence, JLR has announced plans to spend approximately £2.5bn a year on new technology.

“Ambitious targets are being set, and I think the investment and drive to get into electrification as fast as possible is definitely there,” Soundarapandian said. “Today, for major car manufacturers the investment in internal combustion engines is minimal. More than anything else, as they transition to electric, they are focusing more on getting 48V systems added and to get the subsequent performance and emissions boost as they head into electrification.

“What Jaguar have announced are aggressive targets, there's no question about that, but the drive and impetus behind it, and how different companies are investing, is going to increase acceleration to levels that we have not seen before.”

Of course, electrification is not a new concept in terms of us understanding why we need EVs. There are global initiatives across multiple governments to reduce greenhouse gases (GHGs) and the current crop of ICEs are simply going to fall short of meeting these particular targets.

Soundarapandian explained that to get to a point where we have an emissions capability that is compliant then the use of mild hybrids (MHEVs) will be important – which means adding a 48V electric system to an existing ICE. This can achieve an emission reduction of around 13-22%, which in turn will achieve compliance.

He added: “As we head into the future, we’re seeing growth in this particular area, and electrification of existing ICE engines is going to explode. TI has released our new integrated Grade 0 BLDC motor driver for 48V high-power motor control systems, such as traction inverters and starter generators in mild hybrid electric vehicles (MHEVs). The DRV3255-Q1 can help designers shrink their motor system size by as much as 30%, while providing the industry’s highest gate-drive current for increased protection and output power.”

Meeting targets

It has been announced that, by 2026, average fuel economy on a corporate basis needs to be at least 40.4 miles per gallon, and GHG emissions need to be reduced by around 40% by 2030, compared to 1990 levels. Mild hybrids are one way of doing this. However, for designers supporting vehicle electrification in MHEV motor drive systems, there are four main considerations that need to be addressed.

Size: Fundamentally, if you’re thinking about adding an electric motor to an existing ICE, the smaller the total solution size the better. A large concentration of power will mean that you start losing the advantages that this particular machine brings, and it also gets harder and harder to fit.

The DRV3255-Q1 integrates high- and low-side active short-circuit logic, which eliminates external transistors and control logic. By integrating the active short-circuit logic and dynamic fault response, the new motor driver enables designers to not only simplify their designs, but also reduce board space and bill-of-materials cost in 48V motor-drive systems.

“The device that we have released allows you to reduce PCB space usage by about 30%. It's not the actual chip size itself that creates this huge improvement, but in what else it enables on a system level,” added Soundarapandian.

Safety: Since we are discussing part of the drive train and traction system, system level functional safety is a vital component. “Any kind of silicon products that we bring to the market needs to be able to support a system level certification of up to ASIL D, and we build our parts to get us there in the simplest possible manner in what is a complex system,” added Soundarapandian.

The DRV3255-Q1 was designed using TI’s certified functional safety hardware development process and includes built-in safety mechanisms and documentation such as failure modes, effects and diagnostic analysis and a functional safety manual. In addition to the safety mechanisms for the device’s internal failure modes, the digital input/output pins withstand up to 75V absolute maximum ratings to protect the DRV3255-Q1 against an external 12V power supply overvoltage.

“Texas Instruments has been producing ISO 26262 capable parts longer than pretty much anybody else in the market. We have a long history of functional safety compliant systems and parts, and this one has been built from the ground up to support these certifications and systems protections.”

Power: On a 48V rail, beyond around 30kW, the rail is not going to be able to support power delivery. However, Soundarapandian added that the TI Functional Safety-Compliant DRV3255-Q1 allows manufacturers to design a motor-drive system to help enable MHEV systems, supplying as much as 30kW of motor power, which can improve the response time of a 48V motor-drive system in heavy vehicles.

A 48V system is a step-change that original equipment manufacturers (OEMs) can implement to add power for advanced driver assistance system features and managing power-hungry loads such as the heating, ventilation and air conditioning system.

Harsh conditions: A tracking system is going to have to deal with vibration and heat, and so has to be extremely robust and cannot tolerate any failures due to harsh external circumstances. The DRV3255-Q1 motor driver protects 48V powertrain systems from switching transients as high as 95V and load-dump conditions at a wide temperature range (-40°C to +150°C), eliminating the need for protection circuitry.

“The addition of Grade 0 qualification means this device will be able to live at significantly elevated temperatures, and longer over lifetime, meaning it is perfectly situated to play in this market.”

System comparison

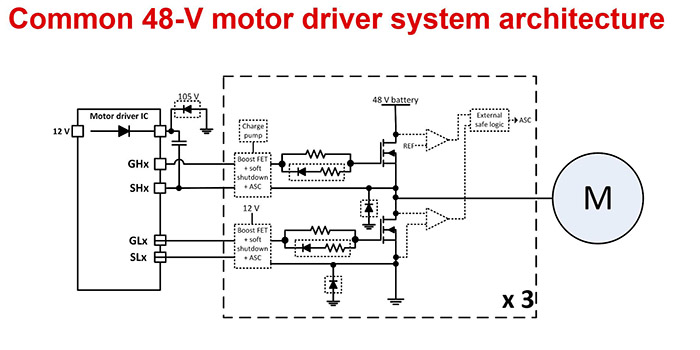

A typical 48V motor driver system looks a little similar to the diagram below. The box with the dotted line signifies one phase, and in a typical brushless DC motor, there are three phases. Therefore, if this is repeated three times, that translates into a lot of components.

This can lead to a crowded and complex board, and routing it is not always easy, as these systems also have to be noise tolerant and immune to external impulses - the more complexity, the harder it is to build.

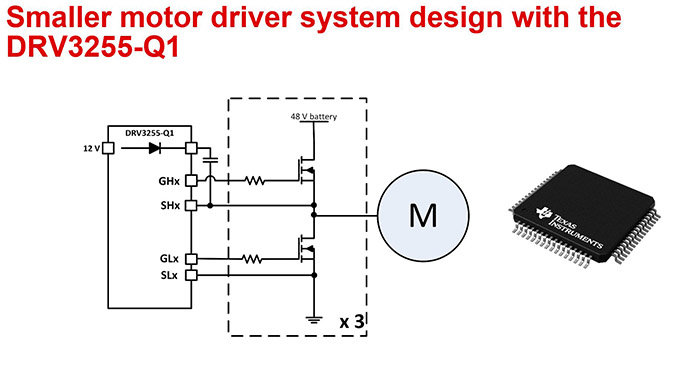

The diagram below shows what the system begins to look like with TI’s new product. Fundamentally, a lot of the features and safety elements, drive capability, and slew rates, are all elements that can now be folded into the part. These are features that are programmable and allow the system designer to focus on the importance of where to situate the power FETs and the motor driver chip itself, in an advantages manner, without having a myriad of passives or other active shutdown circuits and electronics around it to clutter the space.

Soundarapandian added: “You may think that a 30kW motor is large but fundamentally, when you look at the board space and how much you’ve got to play with, taking into account the power semiconductors etc, you run out of space very quickly. So, this is a key advantage that we’re bringing to the table.”

Benefits

Soundarapandian explained that where this particular device delivers over and above exiting industry incumbents, is in the aspect of integration and pulling together a large number of external components, adding: “It’s the industry’s first 3-phase BLDC motor driver to integrate high-side and low-side active short circuit logic

“It’s delivering the complete entitlement power delivery on a 48V system – supporting up to 30kW to function even in heavy vehicles like pickup trucks. From a protection standpoint, this device is rated at 95V. And, on a 48V rail, that gives you a large amount of margin and tolerance for when the system is under harsh conditions and spikes etc.”

The small solution size eliminates multiple components on the board, and it is designed from the ground up to ISO 26262 development standards. This assists the system designer get to an ASIL D certification very quickly.

Accelerating the future of automotive systems

From an automotive systems standpoint, it has been a strategy for TI to focus heavily in the automotive and industrial space for quite some time. The company has around 7,000 automotive and qualified analogue and embedded products, and about 500 new automotive ICs every year, a rate which Soundarapandian stated is only going to increase.

“In terms of system expertise, we’ve also got multiple reference designs that customers can take and use as a starting point. From an automotive quality standpoint, this is something that will become a culture, and given the amount of time we’re spending on automotive investments, that is an important thing for us. It is something that, from the time you define a product, all the way to getting into qualification and release, is a theme that impacts that entire pathway,” he added.

“Supply continuity is another area that Texas Instruments has some advantages. We are a worldwide manufacturing outfit, with 14 manufacturing sites around the globe – in the form of fabs, assembly and test sites. So in terms of supply redundancy and a wide footprint, that is a huge advantage, especially in the kind of situation that we find ourselves in now.”

Soundarapandian explained that TI has a number of proprietary packaging methods and processes that allows the company to get higher density, throughput and of course higher quality from an automotive standpoint. “There’s immediately available inventory and we’re putting in place many different processes and structures so that www.ti.com becomes a one-stop-shop for materials that we can ship at whatever quantity is necessary. Across the board we will continue to make investments to be able to support the automotive market.

“We’re very excited about this particular device, and we truly believe that it is a timely addition to a market that is exploding as we speak.”