Why you shouldn’t throw away your smart meters

You are a utility distribution grid operator faced with the challenge of managing millions of meters. You are planning to deploy advanced metering infrastructure (AMI) with new smart meters to enable automated meter readings, demand response programs, remote connect and disconnect, and improved outage management.

By Vitaly Goltsberg, Energy Business Unit Director, Analog Devices

Despite this, you still need to employ expensive work crews to replace these new smart meters as they near the end of their predicted useful lives. Because utilities or regulatory authorities determine a meter’s useful life based on statistics, most replaced meters are still operational and will be for many years to come!

What if there was a way to keep meters in the field longer and only replace the ones that have reached their useful life?

Extending meter lifetime yields surprisingly high return. Consider an example utility that spends $50 on a meter installation, including the cost of the meter. Assuming a 10-year starting useful life, extending the service of that meter by just two additional years results in saving $10 for the life of each meter. Extending the service by three years increases the savings to $15. If the starting useful life is less than 10 years or the cost of the meter and installation is higher than $50, the resulting savings are even more significant. In addition, the utility defers future capex and reduces electronic waste of disposed meters.

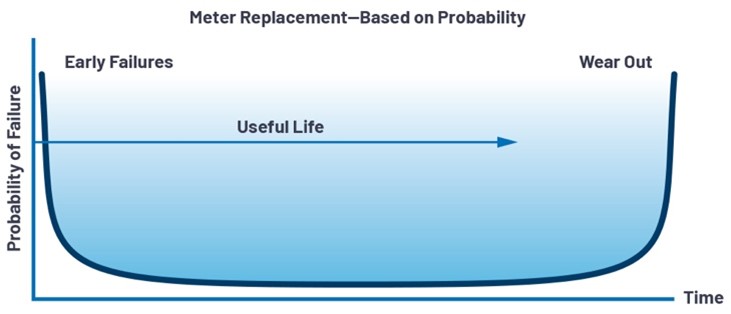

Figure 1. Bathtub curve (Weibull function) represents the expected rate of failure for the entire population, not an individual device.

Determination of a meter’s useful life

Regulatory bodies or utilities determine the useful life of the meter based on industry best practices, which are built on statistical distribution of failures. Typically, this is determined by reliability engineers using a Weibull function, otherwise known as a bathtub curve, as depicted in Figure 1. Engineers use these techniques to ensure that a meter’s power measurement accuracy remains within the allowed class or tolerance limits before it is replaced. This is important to protect consumers from overpaying for electricity, or the utility underbilling electricity, because of a meter’s sensing element that has drifted over time.

Historically, attention has been devoted to reducing early failures through improved manufacturing processes, environmental burn-in, and extensive testing before the meters are deployed. However, the wear out region of the curve, which typically has a Gaussian distribution, is avoided by using conservative—three or more standard deviations—statistical methods to select the device’s useful life and minimize the possibility of out-of-specification devices remaining in service. The biggest drawback of these methods is that most of the time, greater than 99% of the meters removed from operation are still performing within specifications. Until now, there has not been a cost-effective way to verify the power measurement accuracy of each meter.

mSure technology from Analog Devices

mSure technology provides a noninvasive diagnostics system for residential, commercial, and industrial meters. The diagnostics system is built directly into the newest energy measurement integrated circuits (ICs) from Analog Devices and used by meter suppliers worldwide.

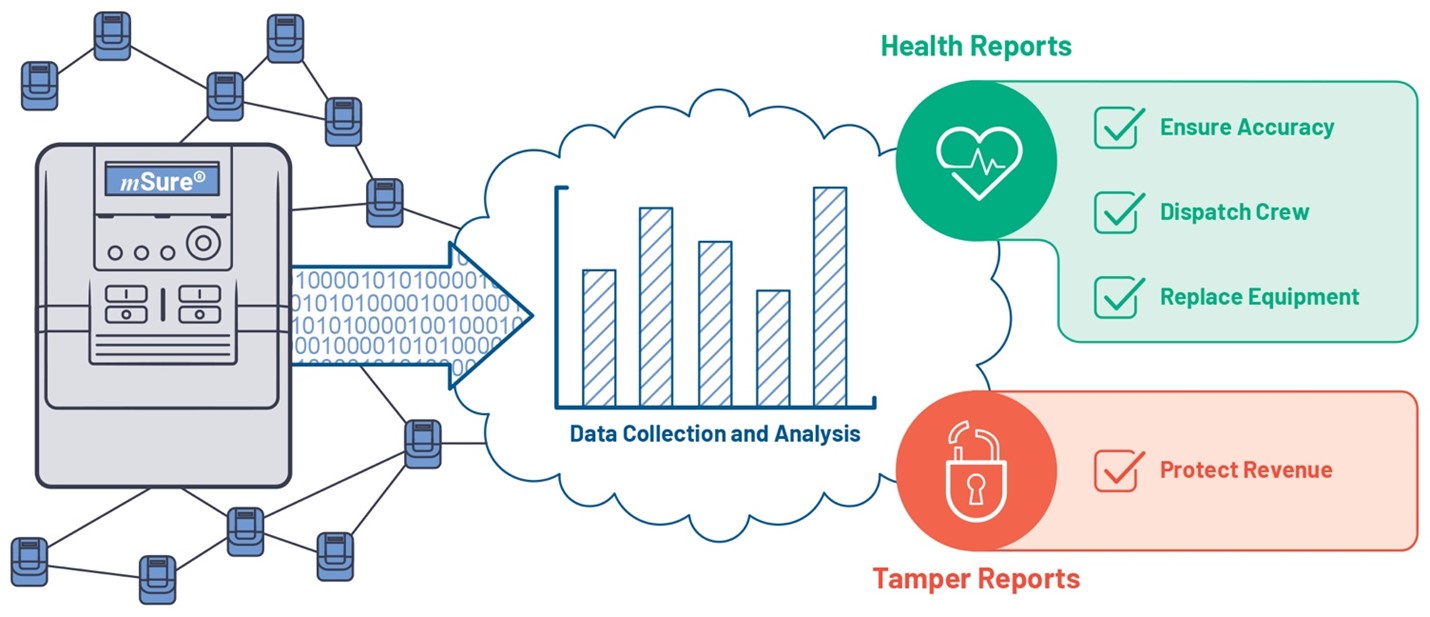

When in operation, the current and voltage sensors are continuously monitored for changes in gain that could be caused by environmental factors, events such as lightning strikes, meter tampering, manufacturing defects, or wear over time. As shown in Figure 2, mSure diagnostic data is sent over the AMI network—with the meter readings—and then analyzed by a service that produces reports, insights, and alerts.

mSure Benefits

Protect Fraud-Based Revenue Loss

Fraud due to meter tampering is a major source of nontechnical loss (NTL) in many countries and regions worldwide. The cost of stolen electricity is typically passed on to honest customers in the form of increased tariffs. Unlike other tamper detection methods, such as statistical methods or spotting current differences between the substation and each of its downstream meters, mSure-enabled meters continuously monitor the meter’s current and voltage sensors for changes that likely indicate meter tampering.

Your fraud investigators have access to reports showing a profile for each tampered meter, including a timestamp of when the tamper occurred, what kind of tamper, and whether there is intermittent tampering. mSure is proven to find difficult to detect tampers such as bypasses and double bypasses of the live and neutral lines. These insights will improve investigation time and speed revenue recovery.

Figure 2. mSure-enabled meters send diagnostic data to an analytics service that produces reports, alerts, and insights.

Eliminate field-based meter sample testing

Regulations and laws in most countries require periodic inspection and testing of installed meters. This process is costly and intrusive to customers as power must be shut off to uninstall the meter. With mSure-enabled meters, your metering staff knows the accuracy of each meter, which allows for elimination of field-based sample testing. Furthermore, work crews, metering experts, and analysts can be available and assigned to higher priority tasks.

Gain billing process confidence

With mSure-enabled meters, your metering managers receive reports and alerts about the power measurement health across your entire meter population, giving you more confidence that your customers are receiving accurate invoices. On occasion, your customers may suspect there is an issue with the meter if they receive a bill that is for a higher amount than they expected.

With mSure-enabled meters, your customer service team has access to each meter’s current and historical accuracy and can respond to inquiries from subscribers without the cost of a field visit. Furthermore, to promote goodwill, you can proactively provide subscribers with a monthly accuracy check, noted on the invoice or available through the payment portal. This capability may also be viewed positively by regulators as a benefit for consumers.

Extend meter lifetime

Most countries have laws that require meters to be replaced on periodic intervals. These intervals are determined by statistical methods, which result in millions of meters being replaced that are still operating within tolerance limits. With mSure-enabled meters, your asset managers know the accuracy of each meter and can replace only the meters that are nearing or exceeding their tolerance limits. This results in deferred future capital expense, reduced waste, and more efficient use of work crews.

Prepare for the future with mSure

Until now, meters have been taken out of service based on industry best practices built on statistical distribution of failures. mSure technology from Analog Devices allows you to keep meters in the field longer and only replace ones that have reached their useful life. With mSure, you are able to extend meter lifetime, eliminate field-based sample testing, and detect meter tampering.