Aircraft sandwich panel allows dispensing on the fly

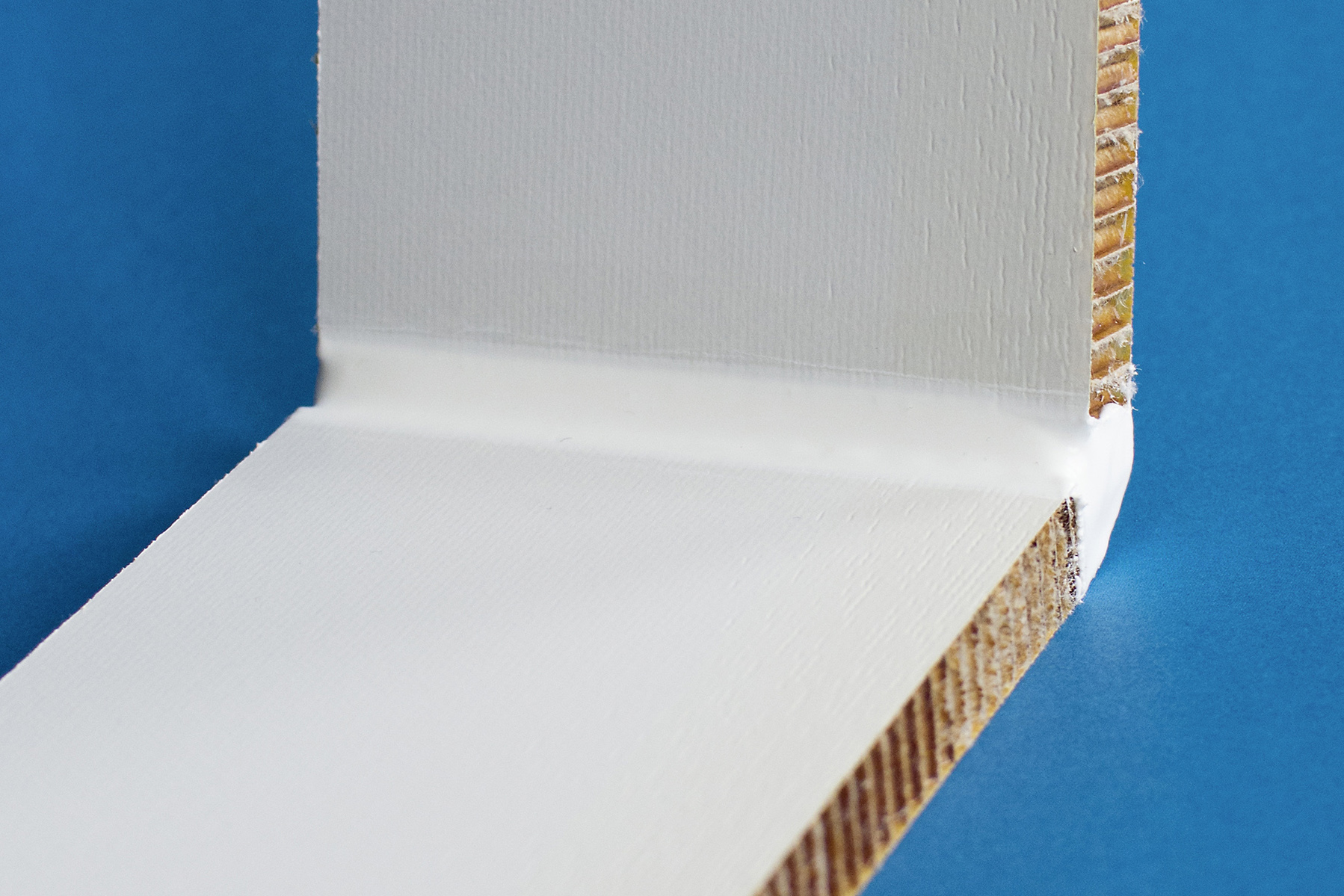

A two-component adhesive for aircraft interiors has been developed by DELO Industrial Adhesives. DELO-DUOPOX AB8390 is particularly suited for bonding of light-weight sandwich panels. Before adhesives can be used in aircraft interiors, they are subjected to various tests to prove their suitability.

The epoxy resin DELO-DUOPOX AB8390 independently fulfils, among others, the requirements regarding fire protection (FST, flammability, smoke density and toxicity) according to CS/FAR part 25 §25.853 (a)(1)(ii)/(d) and ABD0031. This construction adhesive has been developed especially for use in aircraft interiors and features important properties such as good resistance in the temperature range from -55 to 85°C. The adhesive is colourfast in white and will remain so, which has been proved in a storage test during a time period of 1,000 hours at 70 °C and an air humidity of 85%. In contrast to other adhesives which can yellow strongly, DELO-DUOPOX AB8390 offers a robust color result for high-quality applications.

Dispensing on the fly

The DELO-AUTOMIX dispensing system allows the thixotropic epoxy resin to be quickly and easily applied, just like a one-component adhesive. During manual processing, the processing time of 30 minutes also allows a rework on the component. The adhesive cures completely at room temperature. To reduce the cycle times in production, higher temperatures, e.g. 60°C, may accelerate the curing process.

Due to the optimised dispensing behavior in combination with the high resistances, this flame-retardant construction adhesive is not only predestined for load-bearing connections with inserts but also for adhesive bonding in the field of ditch and pot applications.

Currently DELO-DUOPOX AB8390 is used by the Tier-1 supplier FACC in Austria for the adhesive bonding of overhead stowage compartments.