What changes are occurring in the connector market?

The interconnection market is a difficult one for designers and buyers alike. Longer delivery times, product discontinuations, higher minimum quantities and an immense variety of products and variants create uncertainty. Connectors distributor Heilind explains how it supports its customers with service and consulting offers.

Heilind, distributor for connectors and electromechanical components, reports a lot of movement in the market. For developers and product managers it is becoming increasingly confusing. Applications are becoming more diverse and complex. Components would have to provide or deal with more power in smaller spaces.

“The innovation rate for components is very high. Special connectors from niche applications are now also used in completely different areas. As a specialist distributor, we have a good overview of the market and we can offer comprehensive technical advice”, explained Stefan Barrig, Head of Product Management at Heilind. He mentions the trend towards lightweight connectors, such as those used in drones or transport applications. In contrast, there are increased requirements for very robust and large connectors in industries such as agricultural machinery. The spectrum is becoming increasingly differentiated.

Trend towards complete solution packages

The distributor describes different product trends too. The material for connectors is becoming more robust and lighter, while at the same time the performance increases. In general, more and more electronics are being installed using the connectors.

Barrig cites the connection of powerful sensor modules with several functions. Different sensors are installed on a board, which, for example, simultaneously records the values for temperature, humidity, light and motion. This creates new possibilities in building automation and each room can ‘think along’ independently and becomes smart. Here too, it is difficult for the user to keep an overview of the variety of variants, said Barrig: “We offer waterproof sensors, additionally coated, very robust and especially small components.”

“GPS functions in combined harvesters or temperature sensors in offices create a wide range of additional functions in traditional environments. Here, connector manufacturers offer integrated component variants and even complete solution packages” said Stefan Schumacher, Product Manager Connectors at Heilind. The company’s technical advice is actively requested, in order to find the right solutions from the wide variety of variants.

“One example is the smart home market. Here we support users with pre-assembled components and cables. Such packages even contain the control software for the application. The components are already prepared for the local installation.”

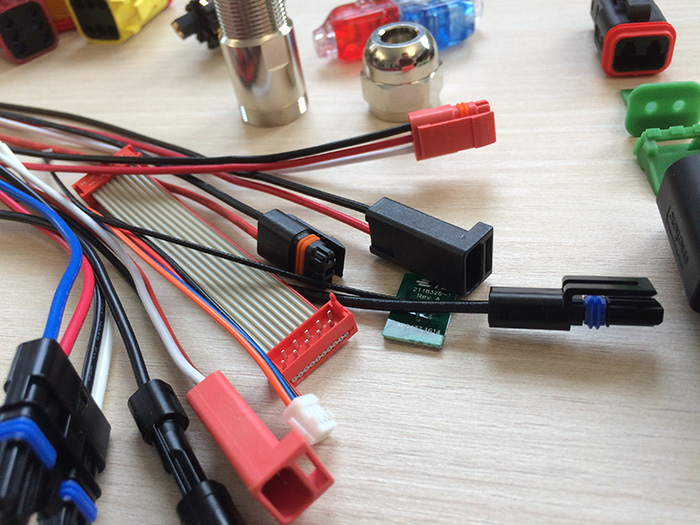

Above: Connectors for industrial applications - the variety of connectors is becoming increasingly confusing for developers and product managers

Standard components become scarce

Heilind wants to expand further into the European market and is expanding its capacities accordingly. “Our customers are under great time and cost pressures. At the same time, we are seeing a shortage of almost all components. As a distributor, we can protect our customers against longer delivery times”, said Stefan Schumacher, describing the need for action. The delivery bottlenecks have so far been compensated quite well by a massively higher stock level. However, this challenge will last even longer. Therefore, Heilind advises its customers to make long term arrangements.

The closer integration of the supply chain of distributor and customer also contributes to more security on the customer side. For example, the component warehouses of customers are increasingly located at Heilind (see image overleaf). The distributor then delivers directly to production for the current demand. The aim is to further reduce manual logistics costs for customers. For this purpose, the electronic order processing will be further expanded in order to automate further sub-processes. “That’s how we help our customers to reduce costs. In turn, we benefit from increased customer loyalty” said Barrig, describing a common benefit.

Trend towards minimum order quantities

There is also a lot of change for component manufacturers. Direct deliveries are increasingly limited to a few major/key customers. For others, the minimum order quantities are drastically increased. After all, many manufacturers restrict their list of distributors to a few partners. “These are additional uncertainties for our customers. The market, on the other hand, has to become more reliable again. For example, nobody wants to order a large package with 10,000 pieces if they only need 800 components. Therefore, as a distributor, we are expanding our services further. We will continue to guarantee our customers that they only need to take the quantities they really need,” explained Barrig.

Heilind maintains relationships with more than 100 manufacturers. Last year’s linecard for Europe comprised 25 providers - this should rise to about 30 manufacturers. For further expansion, the number of employees in Germany has been increased by over 50% to more than 100.

More service

“There is a trend towards value-added services in the US and Asia. For instance, we colour connectors or cut pin headers for assembly and much more”, explained Schumacher. Our own connector production facility is already firmly established in Germany. “Our own certified connector production is a sought-after service.

“For example, we have a connector in our portfolio that can be configured individually from many different individual parts. Here the delivery time at the manufacturer is 16 weeks or more. We require less than a week in our production and can also deliver very small quantities,” said Barrig about the advantages of the service.

As further examples, product managers cite the rewinding of large manufacturer packages to smaller quantities or the reworking of products. In the case of multi-pin PCB connectors, a customer-specific number of pins can be pulled out. In addition, Heilind creates complete component sets for the customer’s manufacturing processes based on a bill of materials (BOM).

Heilind has also set up its own labelling and packaging division. Here, products are marked or housing, security and barcode labels are produced with special printers.