Good vibrations

Vibration sensors play a crucial role in advanced condition monitoring and predictive maintenance strategies. Here, Mark Patrick, Mouser Electronics, explains the pros and cons of the different accelerometer designs.

Digitalisation is transforming the industrial sector. Whether it is manufacturing, utilities, mining, or steelmaking, the application of sensor-based digital networks that can collect, transmit, and interpret data in real-time gives organisations better visibility of their assets than ever before.

This smart capability is delivering advances in critical areas. Take predictive maintenance, for instance. By analysing data from a broad range of machines on the factory floor or out in the field, irregular patterns can be identified, spotting any reliability issues before they occur. This information can be refined over time to deliver more efficient operations – eliminating unexpected down-time and reducing repair costs.

However, effective predictive maintenance strategies rely on a broad range of mechanical and electrical technologies working seamlessly to provide engineers with the information they need. One of the primary components is the accelerometer – a tiny device used to measure a structure’s vibration in an industrial setting. Historically, accelerometers have monitored the vibration performance of large, high-end machinery. However, as the trend towards digitalisation and automation has gathered pace, they are increasingly being applied to high-volume, smaller systems such as machine spindles, conveyor belts, sorting tables, and machine tools as part of intelligent predictive maintenance strategies.

For the reliability engineer then, it is essential to have a good understanding of the technical characteristics of the different types of accelerometers available. This information enables them to make an informed choice when deciding which device to use for a range of vibration applications, weighing up the advantages and disadvantages of each type.

Types of vibration sensors

So, let us look in more detail at both piezoelectric and variable capacitance vibration sensors – the two primary accelerometers used for vibration measurement. These devices each have their pros and cons, as was outlined in a recent technical comparison study published by TE Connectivity.

In terms of how they work, piezoelectric (PE) accelerometers contain piezoelectric crystals that are self-generating and deliver a signal when encountering vibration. Most piezoelectric sensors contain Lead Zirconate Titanate ceramics (PZT) polarised to align the dipoles and make the crystals piezoelectric. PZT crystals are well suited to condition monitoring applications. They can operate with wide temperature and dynamic range, and with a frequency bandwidth >20kHz.

There are essentially two main types of PE accelerometer designs on the market: compression mode and shear mode. Compression mode designs, manufactured by stressing the piezoelectric crystal by loading a mass on the crystal and applying a preload force, have performance limitations. They are susceptible to mounting base strain and have higher thermal drifts.

On the other hand, shear mode designs have an annular shear crystal and annular mass, fixed to a support post. This design has better performance than compression mode designs because it is base-isolated and far less susceptible to thermal stresses, which results in improved stability.

Indeed, these characteristics have led to the shear mode design becoming prevalent for condition monitoring applications.

Now let us assess the performance of variable capacitance (VC) sensors. These devices measure acceleration by noting variation in capacitance of a seismic mass transferred between two capacitor plates. The capacitance change is proportional to the applied acceleration. VC accelerometers need an IC to be coupled to the sensing element to convert the tiny capacitance changes into a voltage output. However, this conversion process can result in a low signal to noise ratio and limited dynamic range. In the main, VC sensors are produced from silicon wafers and fabricated into miniature Micro-Electro-Mechanical-Systems (MEMS) chips.

Comparison tests results

So this, essentially, is how the two technologies work. But how do they measure up when compared with each other through carefully controlled tests? The TE Connectivity study attempted to provide some answers to this important question. Comparing critical vibration specification parameters for a typical piezoelectric condition monitoring accelerometer and a wide bandwidth MEMS variable capacitance accelerometer – both of which had a full-scale range of ±50g.

A range of tests, including frequency response, using a high frequency calibration shaker with a range of 5 to 20 kilohertz, was performed. The sensors were securely mounted for accuracy over the full test range, and a maximum ±1dB amplitude deviation was accepted as the usable bandwidth. The results showed that the VC MEMS sensor had a usable bandwidth up to 3KHz, while the piezoelectric sensor had a usable bandwidth >10KHz.

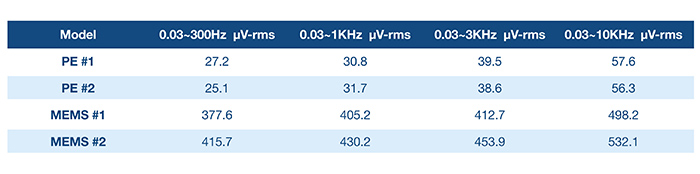

Above: Figure 1. Residual noise comparison at various bandwidths

The samples were placed in an isolated noise chamber and tested with measurement equipment capable of micro-g resolution. The units were tested at the same time to eliminate any errors from outside environment interference. The results recorded for the four different bandwidth settings run, and the residual noise at each setting, are noted here:

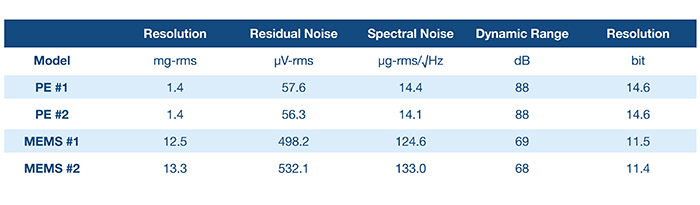

The measurement resolution and dynamic range were worked out based on a 0.03-10 kilohertz bandwidth and are given below. According to the TE study, the PE sensors’ resolution was ~9x better than the VC MEMS sensors. This result was a significantly better dynamic range, enabling the end-user to detect potential problems at a much earlier stage.

Comparing stability and drift

PE is a strong performer in this area, as piezoelectric crystals have been proven over time to be extremely stable in industrial settings. The long-term drift parameters are associated with the crystal formulation used, so an actual value was challenging to present. The study noted that PZT crystals are the most commonly used type in PE accelerometers and are a popular choice of crystal for a wide range of applications.

Variable capacitance MEMS accelerometers also have broad specification limits for long-term drift, depending on the MEMS design structure. A bulk micromachined MEMS sensor usually delivers the best long-term drift but can be more costly and is typically only used in inertial applications.

For condition monitoring, MEMS vendors offer surface micromachined VC MEMS sensors. These are less expensive but do not perform at an optimum level for measurement resolution and long-term stability. The report noted that the MEMS structure of ‘surface micromachined’ designs is not as stable as bulk micromachined MEMS sensors.

Below: Figure 2. Measurement resolution comparison

When comparing ranges in operating temperature, both PE and VC MEMS accelerometers would perform well in condition monitoring applications (ranging from -40°C to +125°C). In specific extreme installations, a higher temperature may require a higher range sensor. In such instances, a charge mode piezoelectric sensor is considered the recommended choice.

Depending on the installation’s specifics and the task at hand, it may require a choice of sensor output signals. Most predictive maintenance installations require an analogue signal from the sensor so the end-user can select which parameters to monitor for which types of machinery. In most circumstances, the DAQ or PLC interface dictates the signal output. Here, an analogue output is the most common choice.

However, for installations requiring long cable lengths, loop-powered 4-20mA sensors are also standard. For smart factories implementing digital Industry 4.0 strategies, digital output signals are becoming more common, as are intelligent sensors with onboard microprocessors. These can make immediate maintenance decisions for the end-user. According to the study, these output signal options should be available in both PE and VC MEMS sensors, and both technologies, therefore, would be capable of delivering this functionality.

Meeting all requirements

In conclusion, the TE study showed that MEMS and PE accelerometers have similar performance in terms of operating temperature, packaging flexibility, sensor output options, and installation ease. However, due to their inherent characteristics, piezoelectric sensors offer a more reliable choice for long term stability. With a comprehensive frequency response, embedded PE accelerometers are ideal from low to high-speed machinery, while offering a sharper signal resolution for earlier failure detection. So, for industrial condition monitoring and predictive maintenance applications, piezoelectric sensors are the technology of choice.