Accelerated RF-component testing for greater production efficiency

Testing RF components such as power amplifiers and front-end circuits demands sophisticated test equipment, with careful engineering of the test setup and control over the surrounding environment.

This article originally appeared in the Sept'23 magazine issue of Electronic Specifier Design – see ES's Magazine Archives for more featured publications.

By Markus Lörner, Segment Manager RF Components, Rohde & Schwarz

In a research and development context, engineers can create a reference test station (Figure 1), typically built around a combination of a suitable vector signal generator and signal analyser which meet the demanding requirements in error vector magnitude (EVM) performance needed for this application.

The test setup needs to safely handle and measure RF signals of appropriate power for the application. It must be able to characterise the components accurately, including their linearity and distortion. Accurately characterising signal degradation when traveling through the DUT based on non-linear effects can require specific capabilities for signal generation and analysis. EVM is a typical figure of merit which needs to be verified using the target application signal type with maximum sensitivity.

To help reduce the cost per device of such complex RF frontend components, the production scenario calls for a solution that is easy to use and fulfils comparable RF performance criteria as the reference station, but streamlined for production to be fast, repeatable, and cost effective.

Characterisation and production test

Once development is complete, test activities are focused on characterising the components, which makes sure that small sample lot of the final product meet the design goals, and subsequently testing on the production line for performance verification and quality control.

In this stage, test operators profit from an easy-to-use one-box solution that consolidates all the necessary functionality including signal generation and analysis while fulfilling the RF performance criteria for characterisation.

Rohde & Schwarz has created the R&S PVT360A performance vector tester to meet these requirements. Its performance is optimised for RF component testing and the compact rack-sized enclosure allows easy use on any production line. Optionally, two transceivers can be housed inside to allow full parallel tests on two different devices.

For users needing to characterise complex RF components under the pressures that prevail in a typical production environment, this performance vector tester combines features and performance such as EVM measurement, frequency range, and modulation bandwidth comparable with industry-leading R&D solutions. It is designed to minimise test cycle time, improving the throughput in production.

The instrument’s vector signal generation and analysis capabilities permit a synchronised approach that accelerates testing while ensuring maximum performance.

With features to help automate testing procedures and ensure precise measurements help streamline the production process and enforce consistent testing protocols. By ensuring that components are evaluated according to predetermined specifications, testing reduces variability and increases the reliability and quality of the produced components.

Faster production test

The most obvious advantage of a streamlined solution that is optimised for production use is the ability to accelerate the test cycle time. In addition to rapid signal generation, acquisition, and analysis, the ability to perform multiplexing and parallel testing to handle several units concurrently, including providing multiple measurement channels, significantly increases throughput.

The flexible buffer in between data capture and evaluation allows the R&S PVT360A to process the data from one RF measurement while at the same time capturing the next. This enables parallelisation, to reduce test cycle time. In addition, with two internal transceivers thereby creating two independent pairs of signal generator and analyser, it can test two devices simultaneously doubling the throughput.

In addition, internal hardware-accelerated sequencing that controls the signal generation and analysis enables test results from the measurements to be output, once a test sequence has been loaded and started, without any external interactions slowing down the process. The generation and analysis functions have separate command lists to ensure maximum flexibility. An internally aligned process flow between both sides performs measurements across level, frequency, and other parameters in minimal time creating a continuous flow of test results.

Easy switching

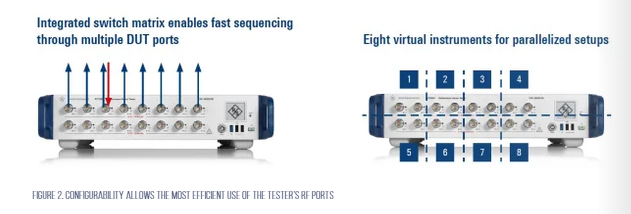

The internal design also contains a switch matrix that maps the fixture ports to the test ports to facilitate quickly loading multiple devices into the text fixture. In total, there are 16 RF ports with a fully integrated switch matrix that enables fast and easy switching between the different ports and hence the different DUTs. On the other hand, taking the data for one port at a time allows running two analysers of the two transceivers in parallel and recording data from two different devices simultaneously.

A smart channel option provides up to eight virtual instruments for easier production planning and instrument programming (Figure 2). All handling, scheduling, and switching between the ports is done automatically with the smart channel option to maximise resource utilisation and speed.

In addition, support for test automation allows users to create test sequences that can be executed without manual intervention. This can include multiple instruments and control of the test device.

Bringing all the elements of the reference test environment into a single, optimised and production-ready, yet flexible, test instrument also simplifies the scaling of test activities if the production volume increases. It is easier to add more measurement channels, expand the test system, or integrate with other equipment to meet increasing production demand.

Conclusion

Testing RF components such as front-ends and power amplifiers challenges product developers to create a reference test station with cutting-edge performance over a wide range. For volume manufacturing, a flexible instrument that enables the key attributes of the reference setup to be replicated in a compact form factor can simplify characterisation and testing, enhancing the speed, efficiency, and scalability of production. This approach improves throughput in production and characterisation and helps reduce the cost per device.