Testing times for EV designers

Electric vehicles (EVs) have been on the market for many years, steadily growing their sales and improving the technology. Right now, it feels like things are about to shift into a completely new gear, if you’ll pardon the pun. Arturo Vargas Mercado, Chief Solutions Marketer, EV battery test, Transportation, NI discusses.

Tesla has become an incredible success, and other carmakers are rapidly transitioning from conventional gas or diesel engines to electricity. For example, Ford is investing $22 billion through 2025 on battery EVs, and Volvo has said it will only make EVs by 2030. Basically, every major automotive brand is making a big shift to EVs over the next few years.

This kind of major change isn’t easy. Carmakers are still learning about developing EVs, and legislation around the world is in a constant state of flux. But in reality, they have no choice – gas and diesel cars will be yesterday’s technology very soon.

The race to meet EV production targets involves new challenges compared to existing vehicles. Batteries are arguably the most important component in EVs – and the most expensive. Also, due to their chemical nature, some aspects of their formation and test cannot be accelerated.

For car buyers, the range offered by an EV is one of the most important criteria in their choice of vehicle. Speed of charging is also important, and it all comes down to a perception of risk. Even when the needs for range for a given usage are met, that perception is hard to change.

To be able to provide credible range and charging speed figures, carmakers need reliable testing. But this testing is complicated, with many different factors to consider.

Battery test challenges

Engineers working on batteries for EVs need to test for a long list of variables: capacity, peak power, thermal runaway, overcharge, temperature cycling, protection systems, hipot (high potential), pressure decay, imbalance charge, short circuit, and dozens of others. All this must be done over multiple temperature ranges and different environmental conditions to ensure the batters perform and fail safely every time.

At the same time, engineers need to test for compliance with IEC 62660, SAE J2464, and other standards. Even managing the list of tests is a big challenge by itself, let alone handling all the data produced to get value out of it.

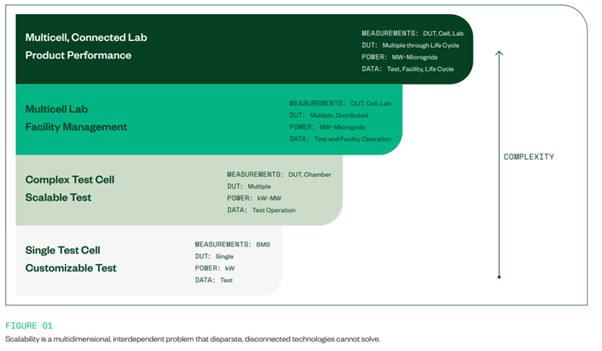

If we consider a hypothetical car manufacturer undertaking all these battery tests, we can see that it falls somewhere in between the Complex Test Cell and the Multicell Lab (Figure 01) categories. One of its main concerns is scaling, while managing the coordination of running the test for all the packs and modules, with some tests sometimes running continuously for as long as several months. The manufacturer also must manage megawatts of power, multiple batteries running different tests, high-channel counts, test cell control, and the test facility itself.

Some of the key criteria that need to be considered include:

- Scalability – from a single test cell to large, multisite, complex test laboratories

- Traceability – robust handling of test result data, to enable reliable analytics and decision making

- Repeatability – so the test can be run again when needed and get the expected results, even years in the future

- Flexibility – so that test cells can be efficiently reconfigured for different batteries or simply to change the number of batteries under test

- Efficiency – to ensure testing processes are manageable and fast enough, rather than being held back by existing technologies and processes

With time-to-market being crucial in the competitive EV market, the way that companies and engineers approach test is important to keep up with the competition. Unfortunately, many companies have been forced to persist in testing with disparate, disconnected tools that, at best, are cumbersome and time-consuming to manage.

Orchestrating battery test

Instead of disconnected, separate tools, how can we create a battery test environment where everything works together without the pain of implementation details?

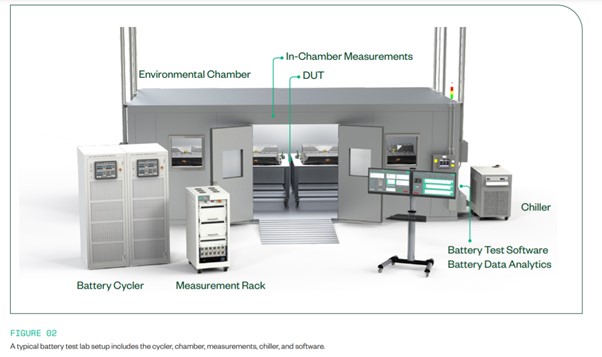

Figure 2 shows a typical battery lab setup, with multiple components that must operate together. Tasks as simple as charging and discharging the battery with the cycler must be synchronised with conditions inside the environmental chamber, as well as the test procedures, the data capture, the measurements, and communication with the battery management system (BMS).

The key to making this work is software. For example, NI’s Battery Test System (BTS) works as a measurement rack and as the software-connected orchestrator of the test, which enables customisation and automation. NI SystemLink, BTS software, and data analytics tools work together to ensure traceability of test results, repeatability of the tests themselves, and management of the entire test-cell operation. From the battery cycler to the measurements on the pack or module, running tests with BTS software helps spot problems before they become catastrophic issues, improves product design, and ensures safety and quality. Additionally, it facilitates coordination of activities between design and test teams to request, configure, run, monitor, and report on test results that inform design changes.

With its acquisition of NH Research Inc. (NHR) and Heinzinger Automotive GmbH, NI added capabilities for battery test, battery emulation, grid simulators, and AC/DC loads and sources. Therefore, completing the power electronics needed for battery or battery-related systems to be tested in a fully software-connected toolchain, for applications including:

- High-power battery module and pack testing – by precisely handling power to and from the battery (cycling), engineers can test batteries in operational conditions, executing profiles of acceleration, braking, charging, environment, and more. This enables them to accurately validate the batteries’ behaviour. They also test for algorithms that improve the safety and performance of the entire EV drive train.

- Battery emulation – engineers can use power electronics devices to emulate the battery behaving any way they need. This enables them to investigate how well their inverter, motor, onboard charger, or even full drive unit meets control, safety, and durability requirements, saving time and reducing hazards involved with using actual batteries to perform the test.

Additional to the technical completion, bringing NHR and Heinzinger Automotive onto the NI family provides operational advantages given NI’s global footprint, manufacturing capability, and over 45 years of test experience.

With NI’s software-connected test platform, engineers can overcome their test challenges in developing batteries for EVs. This enables EV automakers to accelerate development to deliver their products to market faster – so we can all benefit sooner from the shift to zero emission driving.