Innovative high-temperature inks for printed electronics

The global printed electronics market is huge and estimated to reach $23 billion in revenue by 2026, growing at a CAGR of 18.3% from 2023 to 2028 [1].

Increased demand for printed electronic products in automotive and the growth of consumer electronics are two key fuelling factors to drive the market growth. The two critical segments require various reliable printed electronic products for applications from low temperature to high temperature.

The key enabler for reliable device fabrication in printed electronics is functional inks with tunable electrical properties such as conductivity, dielectric strength, and electrical resistance. Celanese Micromax Electronic Inks and Pastes is a global supplier of thick film pastes/inks and recently launched HT (High Temperature) ink series – HT602/603 resistors, HT702 dielectric, and HT802 conductive inks for high-temperature and high-power applications.

HT series inks can be printed additively by using screen printing or nozzle dispensing process on various flexible/rigid substrates including Kapton FPC, Kapton RS, FR-4, Aluminum, Alumina, and glass. The operation temperature of conventional PTF (Polymer Thick Film) ink is typically limited up to 200°C due to the thermal degradation issue of polymeric resin in ink formulations. In the printed electronic industry, high-temperature and high-power applications often require operation temperatures above 200°C.

HT series inks were developed by using novel polyimide resin whose thermal resistant temperature is up to 300°C. Polyimide resin is flexible thermoplastic allowing much more flexibility compared to rigid thermoset Epoxy resins that have been used for the majority of high-temperature applications. Another key benefit of our polyimide resin is its chemical resistance. The combination of high-temperature resistance, flexibility, and chemical resistance of HT series inks is expected to provide solutions for new high-temperature applications in the printed electronics industry which couldn’t be achievable by conventional PTF inks. This article will discuss key technical features of HT inks and their potential applications.

HT602/603 resistors

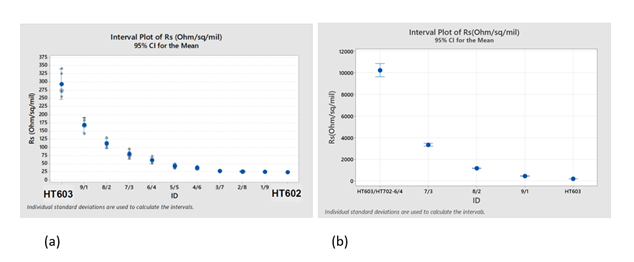

Printable resistor ink can be used to deposit passive resistive components directly on a substrate. Applications include heated floors, pressure sensors, and variable potentiometers. HT602 and HT603 were formulated by adding different types of Carbon black powders in a polyimide medium for high-temperature or high-power applications. The average Rs (Resistivity) is 25Ω/□/mil for HT602 and 300 Ω/□/mil for HT603, respectively. Two HT resistors may be blended to meet specific Rs targets. If a higher Rs value is required than Rs of HT603, HT702 dielectric can be blended with HT603. Figure 1 shows (a) plot of Rs vs. blend ratio of HT603 and HT602, and (b) Rs vs. blend ratio of HT603 and HT702.

Figure 1. (a) Plot of Rs vs. blend ratio between HT602 and HT603; (b) Plot of Rs vs. blend ratio between HT603 and HT702.

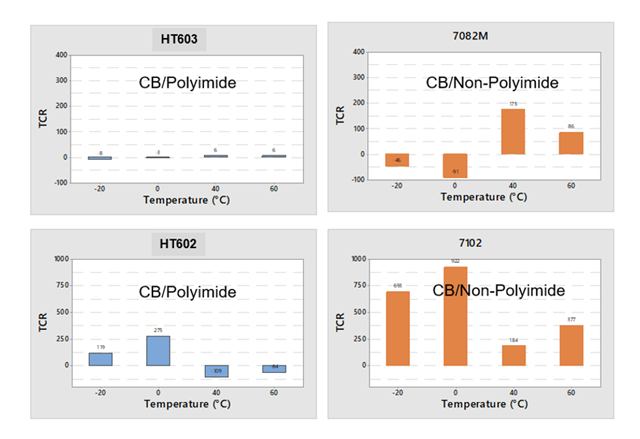

For reliable device operation, the resistance variation of the printed resistor should be minimal with temperatures. TCR (Temperature Coefficient of Resistance) of two HT resistors were measured at four different temperatures as shown in Figure 2. TCR data of HT602, 603 showed much lower values vs. conventional resistor inks (7082M, 7102) formulated with non-polyimide resin demonstrating more stable resistance values of HT resistors with temperatures.

Figure 2. TCR comparison between HT602/603 containing polyimide and 7102/7082M containing non-polyimide resin.

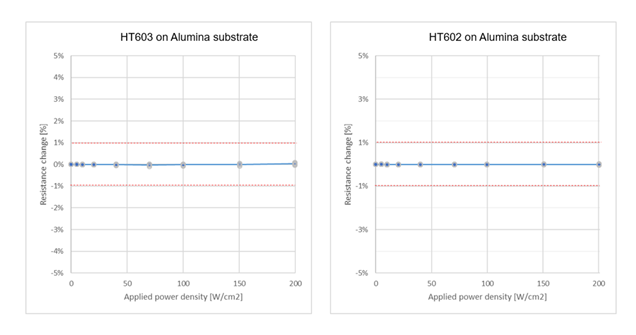

STOL (Short time overload) test was also performed to check how high power HT602 and HT603 could endure without resistance change. Chip resistor’s standard criterion is less than +/- 1% of R change up to 2.5 times of desired operating voltage. Different size of HT resistor pattern was screen printed over Ag electrode as shown in Figure 3 and 0.5 x 0.5mm printed resistor was used to monitor resistance deviation during STOL test. Test condition is 5sec dwelling time with step increase of voltage. Both HT602 and HT603 showed excellent stable resistance up to 200W/cm2 power density (Figure 4).

Figure 3. HT603 printed over Ag electrode on Alumina substrate for STOL test.

Figure 4. STOL test to check Resistance change with step-changing voltage (power density).

HT702 dielectric

To prevent mechanical damage or chemical oxidation of electronic circuits on Flex or Rigid PCB (printed circuit board), the protective layer is applied on top of the metalized circuit. A Conventional protective layer in the PCB industry is applied by photoimagible soldermask (typically epoxy material) on the rigid substrate or high-pressure assisted thermal lamination of Coverlay (polyimide with acrylic adhesive) on flex circuit. Both photoimaging of solder mask and coverlay lamination not only require multiple process steps but also generate waste of materials. The incumbent protective layers also have deficiencies on the material side; the thermoset epoxy solder mask is typically not flexible and coverlay contains acrylic adhesive which is not thermal resistant above 200°C.

HT702 formulated with thermoplastic polyimide resin is more flexible than thermoset epoxy solder mask and has much higher thermal resistance than acrylic adhesive used in coverlay. The combination of flexibility and thermal resistance of HT702 is expected to create new applications in PCB industry where incumbent protective materials have a deficiency. In addition, direct printable HT702 dielectric ink can lower the overall cost of ownership by decreasing process steps and material waste. Good dielectric strength (BDV > 0.5kV), excellent chemical resistance and excellent adhesion on various substrates are additional benefits of HT702. To achieve good dielectric strength and uniform coverage without pinhole defects, 2~3 printing and drying cycles are recommended.

HT802 conductor

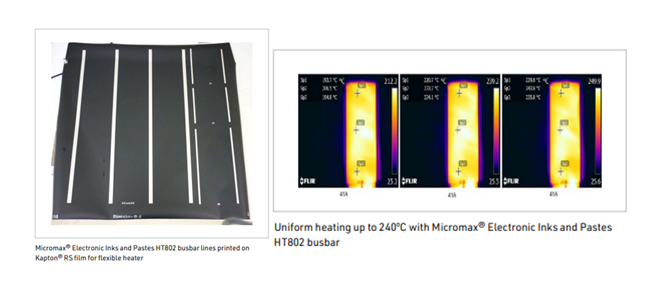

HT802 is highly conducive and thermal-resistant ink formulated with silver powders and polyimide resin. High thermal/chemical resistant polyimide resin enables HT802 to be applicable to high-temperature applications such as electrodes for heaters or platable conductors where the plating process involves a caustic acid/base bath process. For example, figure 5(a) shows the HT802 electrode printed on 16 x 16” Kapton RS flexible heater. Uniform heating performance was achieved up to 240°C (Figure 5(b)).

Figure 5. (a) HT802 printed on Kapton RS film as an electrode for flexible heater fabrication. (b) Uniform heating up to 240°C was demonstrated.

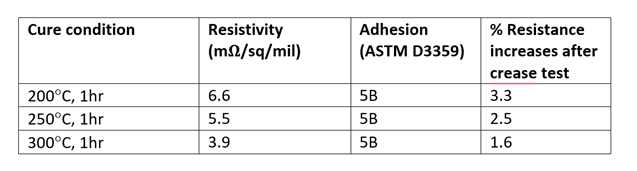

Table 1 shows the performance of HT802 with different cure conditions. Resistivity decreased with higher cure temperatures while maintaining excellent adhesion on Kapton film. Interestingly, crease resistance also became better (lower % increase of electrical resistance) when HT802 was cured at higher temperatures.

Table 1. Resistivity, adhesion, and crease resistance of HT802 with cure condition. HT802 was screen printed on Kapton film.

Summary

Micromax Electronic Inks and Pastes launched a new HT product line using noble Polyimide resin chemistry for high-temperature printed electronics applications. The combination of high thermal/chemical resistance, flexibility, and additive printability of HT inks is expected to provide solutions for various high-temperature applications on both flexible and rigid substrates.

[1] Printed Electronics Market Revenue Trends and Growth Drivers | MarketsandMarkets