Industry 4.0 business models based on embedded computers

There is no question that the digitisation of all areas of life and work creates new business models. In the DACH region, the connection of digital transformation of products and manufacturing has been dubbed “Industrie 4.0” – industry 4.0. Obviously, this is not just about setting up a PC at the manufacturing line and hooking it up to the internet. Rather, the goal is to gain a competitive advantage, be it through raising efficiency or generating new offers, from leveraging the data collected as well as networking operational technology (OT) and information technology (IT).

Kontron, a subsidiary of the S&T technology group and a long-standing supplier of embedded computing- and IoT technology, demonstrates this: On its boards and modules operating on the latest Intel, AMD or NXP processor generations, Kontron integrates a chip supplied by its partner Wibu-Systems. It not only contributes security functionality but integrates license management as well. In practice this means that customers using Kontron embedded computers can develop new business models based on machine or device usage.

Today barely a machine in industrial use is not software-controlled. In industrial applications, machines are also networked to allow for transmission of data to the control rooms, for storing it for big data analytics in the data center or even the cloud. Edge and fog devices contained within the machines on site transmit the data. These devices are mostly embedded computes that are equipped to handle security- and license functionality right at the machine. This lays the technological groundwork for use-based billing models, if the appropriate hardware and a software framework are available. Though not an extensive list, other options include the following scenarios:

Manufacturer-owned Machine: pay-per-use

The so-called “operator model” is not just sensible in cases where the user doesn’t expect the machine to be cost-effectively used to capacity, but still considers it indispensable in the manufacturing environment. Other use cases include scenarios where availability- and service requirements for a particular machine are high, making it a viable alternative to hand off all service and support to the manufacturer as part of the operator model. In this manner, availability is guaranteed without the need of user intervention. The manufacturer benefits from retaining ownership of all the machines. This enables accessing all manner of machine data generated by the devices operated. By aggregating and analysing the data over a wide array of machines, big data analysis can offer valuable insights about maintenance work, development, or troubleshooting. Pay-by-use regimes are especially suitable for processes with easily measured procedure such as with punching machines, spot welding machines, or laser cutters. As an alternative, the number of workpieces processed can be used for billing. This model is commonly used in the industrial automation sector.

User-owned Machine: limited Number of Usage Instances

This scenario is suitable, among others, for leasing agreements in which the manufacturer repossesses the machine for resale, and comparable to mileage-based limitations on car leases. The user benefits from a lower purchase price than that of an unlimited-use machine. For the manufacturer, the user agreements means he has clear information on wear and depreciation, allowing him to calculate the resale value. For instance, printing presses can be limited in terms of the number of print processes. In addition, usage can be limited in terms of hours of operation. A typical use case of leasing models is found in medical technology, for instance the use of CT machines.

User-owned Machine: Functionality limited via Software

This model makes sense when only a few functions are predictably going to be needed. With limited functionality, the machine of course will be less costly for the purchaser, while the manufacturer can configure a product line’s functionality though the software, sparing him the expense of developing and producing different hardware versions. Even scenarios in which the manufacturer subsequently activates dormant functionality upon user request (and purchase) are possible. This business model is common in many industries already, and is particularly suitable for gaming machines in the entertainment industry, or in industrial automation, releasing additional functionality for manufacturing robots.

The models letting the manufacturer retain machine ownership have bottom-line implications, too. While the purchase of complete machines economically counts as an investment, use-based pricing models are handled as operating expenses. Shifting expenses from investments to ongoing operating costs through pay-per-use models can be especially useful in industries in which expensive machines mean high investment costs.

License Management for 3D Printing or Textile Machines

There is also the option of protecting the rights of spare parts manufacturers in the age of 3D printing by implementing procedures for license control. Providers of 3D print templates could use the Wibu chip to grant or withdraw printing licenses. They could allow, for instance, the reproduction of a spare part three times using a purchased, and thereby licensed, template. For every additional print run, further licenses would need to be acquired. The license chip would make quickly determining whether a license is valid possible. Original equipment manufacturers (or manufacturers of original equipment templates) could create a business model based on the legal, paid for distribution of 3D print licenses. This would reduce the black market for illegal print templates. Users would have an assurance of using only original equipment. A possible use case is the 3D printing of customised brand sports shoes in certain shops offering select patterns or imprints. In this case, too, verifying whether the respective print is covered by a valid license and how many shoes can be printed under this license would be possible. Even reverse engineering the printer itself with criminal intent would not make it possible to print unauthorised parts or products due to missing licenses. This offers another layer of protection for manufacturers’ intellectual property.

Also, it is possible to install the Wibu chip into textile machines such as power looms to control license compliance for certain patterns and a fixed number of woven products featuring this licensed pattern.

This has to be supported by the underlying software framework by offering the technical capabilities, of course. An ideal setting allows the activation during operations without manual work on the machine.

Included in the Hardware: Pay-per-use

These licensing models aren’t fundamentally new, and the underlying technology also is tried and true. With the integration of the Wibu chip, Kontron takes it a step further. Up until now, implementing use-based billing models always required additional hardware. Examples include dongle- or smartcard solutions added onto existing hardware.

This in turn required manual interface access. This is always difficult with embedded hardware, and in the worst-case scenario there is no vacant interface available at all. Integrating the Wibu chip with Kontron boards and modules, this additional effort becomes unnecessary, as the hardware is already included, ready to be activated at a single click.

The reliability and fail safety of the chip soldered onto the board is significantly higher than that of a smartcard or USB stick which is merely plugged in. The Kontron concept allows for the implementation of licensing solutions in rough everyday industrial applications in which constant shocks or vibration make plugs or cards unreliable.

The solution christened “Kontron APPROTECT” and “Kontron APPROTECT Licensing – Powered by Wibu-Systems” consists of a smartcard chip built onto the board. Through offering encryption right on the Kontron hardware, it guarantees the security of application data and program code. Kontron is now integrating the chip provided by partner Wibu-Systems into all new modules and motherboards, giving users the option to decide which licensing- or security functions to use. Older Kontron modules featuring PCI Express Mini- or USB interfaces can be upgraded with the chip using a retrofit kit.

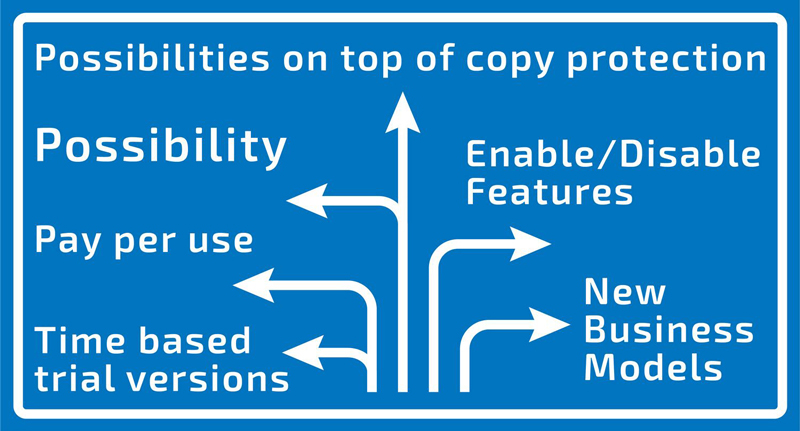

Kontron markets the chip’s additional licensing functions under the “Kontron APPROTECT Licensing” brand. The chip and software framework offer activation, based on the following criteria: time, number of calls, or features activated. This offers a wide array of creative business models using existing or newly purchased machines with Kontron embedded computers, greatly expanding manufacturer’s options beyond pure product distribution.

On the developer front, the effort of development using these functions is fairly low. The functions itself, of course, need to be integrated into the application’s source code. Kontron offers the appropriate Wibu-Systems SDK and will assist on demand with a support team, or by establishing contact to Wibu. The chip can be accessed through the operating systems Windows and Linux used by Kontron, which can be addressed with common programming languages such as C, C# or Java.

Having the activation as part of the source code brings a simple, yet effective advantage: instead of transmitting the programs in part or as a whole into the machine via the cloud or network, a license code of usually just a few bytes will suffice. This avoids creating bottlenecks. The licensing server is offered by Wibu-Systems, guaranteeing flawless communication between the chip and server.

Upon request, Wibu-Systems will cooperate in developing and implementing additional functionality to the Wibu chip. S&T Technologies, a S&T technology group affiliate, will support Kontron customers requiring consultation on new technological processes or potential business models.

The licensing element is a web-based administration solution with which licenses can be created, activated, updated, or tracked. It can be integrated into existing ERP and CRM systems, warranting uncomplicated order processing. Further functionality makes it possible to tie licenses to certain hardware elements, ensuring they will only be valid on the assigned hardware and cannot be re-used. An extensive software interface is available for integrating the different licensing models into applications. Kontron innovation turns Industry 4.0 into business 4.0.