How to select the best slide switch for your application

Slide switches are one of the older technologies available for selecting, making, or breaking an electrical circuit. However, due to their purely electromechanical nature, they remain popular as low cost and reliable means of controlling or interacting with some aspect of a machine or process. Cathy Zhao, Global Product Manager, Littelfuse discusses.

Designed to be actuated by the human finger, slide switches are used in a wide range of applications that require a simple interface between human and machine. There are several key areas to consider when selecting a slide switch.

Slide switch basics

Slide switches are identified by their horizontally sliding actuator, which opens or closes the switch contacts. These types of switches come in all shapes and sizes from ultra-miniature to larger, high-power models. They can also incorporate multiple switch functions

Slide switches are easy to integrate into a design and give engineers more design flexibility and options for size, termination styles, actuation types, ratings, and packages. Many miniature power slide switches are now compliant with the latest UL61058-1 standard. These devices can be used in a variety of applications including consumer, commercial, HVAC, industrial, security, telecom, and more.

According to a report published in 2021 by Global Industry Analysts Inc (GIA), the global market for switches is projected to reach a size of $4.9 billion by 2026, growing at a CAGR of 1.3% over the analysis period.

The global market for switches was estimated at $4.5 billion in the year 2020. The slide switch segment specifically is projected to record a 1.5% CAGR and reach $1 billion by the end of the 2026.

Physical size and power switching capabilities

The size of the switch is significant, as it will take up expensive printed circuit board (PCB) space in devices or equipment. However, often the size is determined by the required current rating needed to switch. For example, a power supply application which will need 3 A to 15 A of carrying current capacity will typically be larger than a small signal switching slide switch. Slide switch manufacturers, like C&K, offer many switches in varying sizes and power ratings to meet most design needs. For the switching of the signal circuits with a rated current of 0.3 A, the subminiature JS and miniature slide of the SS, SK, JS, and PCM series meets the requirement of both smaller size and functionality.

For low current (dry circuit like 10 uA current) applications, slide switches must often meet miniaturization requirements as well as concerns over the level of protection and the contact’s normal force. Oxidation is a common issue in miniature switches.

Miniature switches with gold plating on the contacts to actuate the switch helps prevent oxidization of the switch contacts over time and increases the overall lifespan of switches. The ultraminiature slide switches like the PCM and AYZ (AYZ minimum size 7.2mm X 1.5mm) are designed to address these concerns.

High power switches, like C&K’s 1000, L, S, and V series all have different features to appeal to different market needs, such as the V series being designed for power and line voltage selector applications.

Contact plating

In general, the contact plating of the slide switch is either silver or gold plated. Silver material is commonly being used for power and signal level switching. Gold plating option offers enhanced performance and environmental protection. Whether end-products are exposed to damp air or Sulfide containing environments, gold plating options decrease the potential risk of electrical short circuits due to the age of plating with dendrite growth caused by silver migration. In addition, the gold plating is ideal for low level ratings or dry circuits.

On slide switches, the usage of lubricant could impact the characteristics such as conductivity, working temperature, arc suppressing effectiveness, operating force, haptics, mechanical, and electrical life. Due to no industry standard, it is a challenge for engineers to balance among the characteristics of grease including lubricity, adhesion, broad temperature compatibility, oxidation resistance, and compatibility to the plastic material.

C&K has spent great efforts on strengthening the capability of lubrication evaluation used in various product series for different customer applications through our American lab. One success story is combining the use of gold plating and lubricant for one customer with the PCM series in a fire alarm for security to greatly improve the performance and another case is adjusting the JS series for a CIPer controller in an industrial application for a leading customer.

Number of circuits and positions

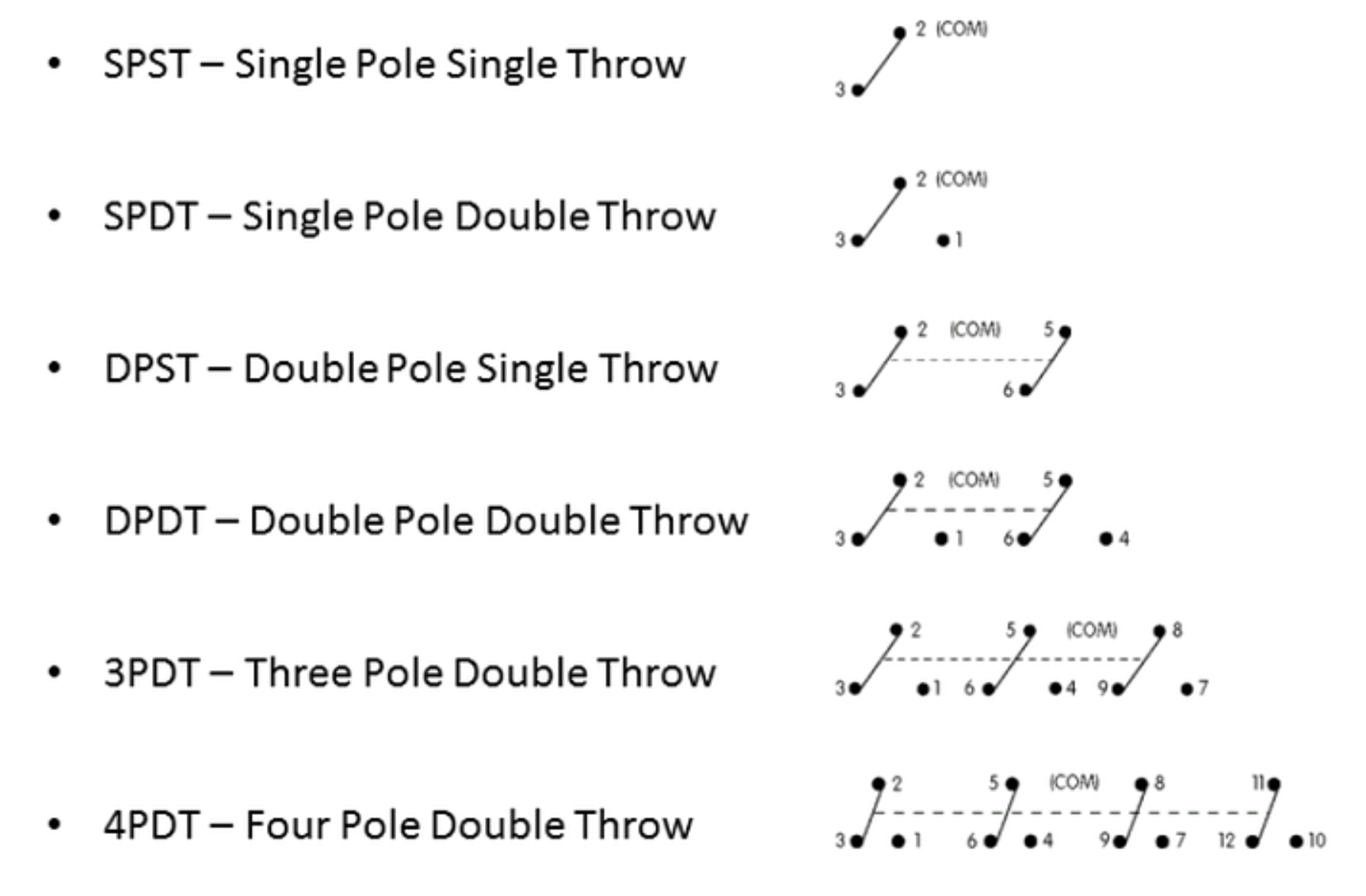

Whether the application calls for a power or signal slide switch, manufacturers offer a wide range of switching configurations within a single switch body (multiple poles, multiple throws). This gives designers more options to control multiple loads and functions simultaneously. The benefit is to offer PCB space-savings and flexibility to the circuit board design, while providing multi-circuit control with a single switch. Slide switches follow a widely used system of acronyms to denote number of poles (number of circuits) and number of throws (number of positions that a switch can close):

Travel

Another consideration is travel, or how far the actuator is moved when actuating the slide switch. A combination of the height of the actuator, the force required to move the actuator, and the length of travel will fundamentally change the feel, or haptic that the user will experience. Slide switches are offered in a wide variety of options to meet design needs, whether that is a higher force, longer travel part for use with gloved hands, or a light short travel.

Termination style

Termination options, including surface mount, panel mount, PCB through-hole, or right-angle variants, also must be considered. The choice is again often limited by size, as actuating a larger slide switch mounted on tiny SMT PCB connections can be difficult to integrate, whilst maintaining a good connection between switch and PCB. For smaller devices where surface mount termination is a must, a slide switch with SMT J bent termination is often preferred.

Designed for use in applications that requires a reliable multi-function switch with a low profile and limited PC board footprint, J bent slide switches are ideal for use in consumer audio and video equipment, test and measurement equipment, and home automation and alert systems, such as thermostats and smoke and carbon monoxide detectors.

Special requirements

For demanding applications and those with unique design challenges, slide switches can be customized to meet specific functionality, size, load, and operating life requirements. Slide switches are now available with custom actuator heights, specific operating forces, upgraded materials for reflow soldering process, and gold plating used in the damp environment that may also contains sulfide. Further customization options, depending on the application, include positive detent, sealing, and shorting or non-shorting contacts.

Conclusion

Although a legacy technology, slide switches are still an integral mechanism in many of today’s most innovative end-products. Slide switches provide a reliable, simple, and low-cost interface between human and machine. Easily customsaable to meet application demands, slide switches will continue to be the chosen solution for designs with basic functionality requirements.