Confident obsolescence management with Extension-of-Life

Semiconductor manufacturers regularly announce the planned obsolescence of older products, to direct their resources towards supporting new product introductions with the latest technologies. The effects of these natural cycles challenge OEMs to ensure the sustainability of their products. This is especially true in high reliability, long life cycle products in sectors such as medical, industrial, transportation telecomms-infrastructure or aerospace.

By Thomas Skarbek, Director, Supplier Development & Strategic Programs, Rochester Electronics.

Manufacturers in these sectors must continue supporting their products for 10-20 years or sometimes longer and be subject to potentially millions of dollars in redesign and qualification costs if the original device is no longer available. Other factors such as use of COTS components, RoHS and REACH legislation and the growing threat presented by counterfeits, intensify obsolescence-management challenges.

Approaches to obsolescence management

As of January 2015, obsolescence management has its own international institution: the International Institute of Obsolescence Management (IIOM). The IIOM evolved from the Component Obsolescence Group (COG), but is by no means the only resource dedicated to this subject. The IEC has already established the standard IEC 62402 covering obsolescence management and knowledge-sharing portals such as obsolescence.com tackle the issue from the perspectives of a variety of industries. Obsolescence is always ongoing, everywhere, and diverse groups from government, industry and the academic world continue to develop processes in the search for an effective, systematic response.

As far as electronic components are concerned, the power of today’s consumer markets has dictated shorter and shorter lifecycles for standard ICs. The typical lifetime is now around three years, including all phases through introduction, maturity and decline, ultimately leading to obsolescence. Since consumer brands tend to refresh their products more quickly than this, they can accommodate an End Of Life (EOL) notification from a chip maker relatively easily.

EOL can be a rather more significant problem for producers of equipment that must remain in service for long periods. Over time, it can become increasingly difficult to source the components from familiar and trusted suppliers. Buying from unfamiliar or unauthorised sellers, or brokers, carries an increased risk of acquiring substandard or counterfeit stock.

Some companies may consider designing an ASIC as a pin-for-pin-compatible replacement for the EOL component. This can be time consuming, and is also technically complicated as the design must take into account significant software and timing issues. Another approach is to embark on a complete product redesign using new components, but this demands extensive engineering commitment as well as costly and time-consuming re-qualification.

When the OCM publishes the schedule for EOL, there is a Last Time Buy (LTB) opportunity for customers to secure sufficient stocks to support future production needs. The purchase has to be finely judged: there is a risk of under-purchasing, leading to shortages later when suitable product is even more difficult to find. Buying too many parts, on the other hand, represents an excessive unwanted investment that may be difficult to recover by trying to re-sell the components into the open market at a later date. These factors are above and beyond the fact that the customer must incur the cost of procuring the full quantity to support a programme to its completion, thereby impacting cash flow and the opportunity costs associated with pursuing other endeavours. Add to this the fact that most OEM’s do not have the capability and infrastructure to hold product for extended periods of time without the risks of long term storage issues.

Developing an obsolescence management plan early in the design of a new product is critical and can help guide component selection. Manufacturers can use automated tools that will generate alerts when manufacturers issue EOLs for components on their BOM. This, combined with knowledge of projected production volumes, time in market and total supported lifetime, as well as the OCM’s EOL policy and support record, an effective obsolescence plan can be implemented that will mitigate and EOL event and thereby minimising LTBs and the quantities required. Traditionally, taking the LTB plunge has been the only course open to many OEMs needing an emergency obsolescence-management solution.

A better way

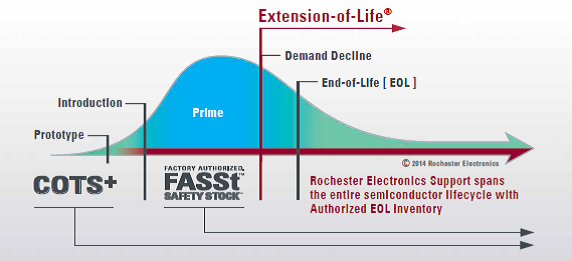

More than 60 of today’s leading OCMs are putting in place lifecycle support plans that rely on a contractually authorised specialist, an EOL partner, such as Rochester Electronics. Under this partnership Rochester Electronics has received billions of finished goods, die/wafer and intellectual property, ensuring an authorised source of supply for ongoing OEM programmes. In addition to this 'Extension of Life', Rochester Electronics can often support components that may be unavailable from traditional distributors, or subject to long lead times. Rochester can supply active components from Factory Authorized Safety Stock (FASSt). Figure 1 shows how these two strategies cover the product lifecycle from introduction to beyond end of life. EOL covers not only in-stock factory-finished inventory, but also the continued manufacture of devices using the original die/wafer, the use of the original OCM’s intellectual property to re-introduce a product or even complete re-creation of components from scratch, all with the authorisation of the OCM. All finished goods are 100% factory traceable. Once acquired from the OCM, they are stored in environmentally controlled conditions to preserve their integrity and minimise degradation.

Figure 1 - EOL gives access to factory-authorised stock beyond conventional end of life

Case Study: MC68040 EOL

Rochester has a relationship with Freescale Semiconductor (formerly Motorola) that allows access to end of line materials, including finished goods, die/wafer and OCM Intellectual Property.

Rochester’s support for customers of the popular Freescale MC68040 32-bit MPU shows how Rochester’s EOL works in practice. The MC68040, originally introduced by Motorola, was extremely popular throughout the 1990s and 2000s, particularly in high-performance VMEbus computing systems (Figure 2) used in telecomms infrastructure, avionics, industrial workstations and minicomputers. Freescale discontinued the MC68040 in November 2014. The last shipments will be made in November 2015.

Figure 2 - The MC68040 is widely used in SBC platforms

Rochester will soon release pre-production units of new devices built using original die and will begin OCM-authorised production later in the year. This will ensure a long-term supply from a trusted, OCM-authorised source, which is of particular value to customers with long-lifecycle, high-reliability end products who would otherwise need to consider a costly re-design/re-qualification program. The components can be relied upon to meet the OCM specification in every respect while being stored and handled in accordance with Rochester’s audited quality standards.

Rochester is also working with Freescale to provide ongoing support for other processors such as MC68020, MC68030, MC68060 and MC68360 product families. Freescale has recently issued an EOL notification for the MC68360, for example, which took effect at the end of April, and is endorsing Rochester’s continued support for this device going forward.

This example illustrates an effective approach to component life extension. Now that a model is established, major chip manufacturers are beginning to commit to supporting products for lifetimes of more than 10 years. This should significantly improve support for customers facing the very real challenges associated with obsolescence.