Tiny nanostructures impact high-speed optical devices

With new technology getting smaller and smaller, requiring greater energy support with more options, University of Cincinnati physics research points to new robust electrical potential using quantum nanowire structures. The tiny miracle fibers may lead to advances in sensitive electronic technology including heat detecting optical infrared sensors and biomedical testing, all of which can fit inside small electrical devices.

Supported by a battery of NSF grants, the UC research team has worked with a collaborative team of physicists, electronic materials engineers and doctoral students from around the world –– all to perfect the growth and development of crystalline nanowire fibers that form the backbone of nanotechnology.

But to fully apply this technology to modern devices, UC researchers are first looking closely –– on a fundamental level –– at how energy is distributed and measured along thin-strand nanowires so small that thousands of them could theoretically fit inside a human hair.

"Now that we know the technology can be developed, we need to understand exactly how the electrical processes work inside the nanowire cores," say Howard Jackson and Leigh Smith, professors of physics at the University of Cincinnati. "After finally perfecting a standardised process for growing and developing crystalline nanowire fibers with our partners at the Australian National University in Canberra, we have been able to take it one step further.

"Using a combination of materials like indium gallium arsenide, we can develop thin nanowire cores with protective outer shells."

Even with incredibly small masses, it turns out that the unique nanowires have unusually large spin orbit interactions, which the researchers find can conduct electricity really well and may help improve heat sensing infrared detectors for small military devices.

Jackson and Smith are presenting these remarkable findings at the American Physical Society Conference, in Baltimore, March 16, titled, "Exploring Dynamics and Band Structure in Mid Infrared GaAsSb and GaAsSb/InP Nanowire Heterostructures."

The researchers claim the secret to the success of this multi-collaborative effort is in the combination of materials used to create the nanowires. Initially grown at the Australian National University in Canberra, the nanowires are sprouted from a combination of beads of molten gold scattered across a particular surface.

As the process is heated inside a chamber using indium gallium arsenide gases, long microscopically thin core fibers sprout up from between the controlled surface environment.

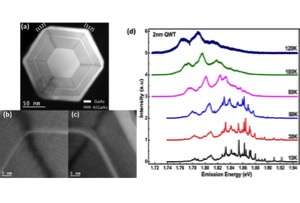

Other material combinations are then introduced to form an outer shell acting as a sheath around each core, resulting in quantum nanowire semiconducting heterostructures all uniform in size, shape and behavior.

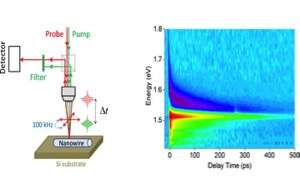

After the fibers are shipped across the globe to Cincinnati, Jackson, Smith and their team of doctoral students are then able to use sophisticated equipment to measure the electrical and photovoltaic potentials of each fiber along its surface.

In earlier research, the collaborative team found extrinsic and intrinsic problems when the fiber cores did not have the outer sheath-like shells.

"If we don't have this outer sheath, the nanowires have a very short energy lifetime, says Jackson. "When we surround the core with this sheath, the energy lifetime can go up by an order or two orders of magnitude (power in watts)."

And while gallium arsenide alone is a very common semiconductor, its energy gap is large and in the visible range, which absorbs light. To achieve success in detecting optical heat or infrared, the team says using indium gallium arsenide fibers produce smaller energy gaps that can be used successfully in optical detector devices.

"The goal for one of our research equipment grants is to work with the local L3 Cincinnati Electronics Company, which makes infrared (small gap) detectors for night-vision imaging for military applications," says Smith.

"Future direct applications for this type of technology also include medical devices that detect body heat, as well as remote sensors installed in iphones that can be used for environmental purposes that detect and measure heat loss in houses."

The researchers say this new nanowire technology is particularly unique because it can turn different types of light into an electrical signal, and in this case it means turning an infrared light into an electric signal that can be measured.

Smith explains that with the geometry of the nanowires you can have a long axis running the length of the wire, which gives you lots of possibilities for absorption as the light comes down, but then you also have this very small diameter.

"When contacts are interspersed along either side, essentially then the electrons in the holes don't have to travel very far before they are collected," says Smith. "So in principle it can become a more effective detector as well as a more effective solar cell."

"When you get to very small dimensions in nanowires that are small in diameter, but are a few microns long, those properties then change and can show a quantum (finite number) of properties and become almost one-dimensional," says Jackson. "The physics then changes as you change those sizes."

Jackson and Smith found that the nanowire's ultra-thin outer shells functioned best at widths of four to eight nanometers, which is 25,00 and 12,500 times smaller respectively, than the diameter of a human hair.

When looking at the overarching benefits of working with microscopic nanostructures the researchers see tremendous payback potential for its ability to pack much more high-energy efficiency into small devices with finite space.

It's getting closer to a win-win for everyone, they're saying, especially when this research enters the next stage, bringing it closer to functioning inside electronic and optical sensor devices.

"Our fundamental investigation is still a step away from a direct optical device application," says Jackson. "But you can clearly see over time that this collaborative research has made an impact."