The industrial potential for graphene materials

A 2D material with exceptional properties, graphene is the focus of Yole Développement's latest report: "Graphene materials for opto & electronic applications". With properties including ultrahigh electrical and thermal conductivities, wide-range optical transmittance and excellent mechanical strength and flexibility, graphene is a promising material for emerging and existing applications in printed & flexible circuitry, ultrafast transistors, touch screens, advanced batteries and supercapacitors, ultrafast lasers, photodetectors and many other non-electronic applications.

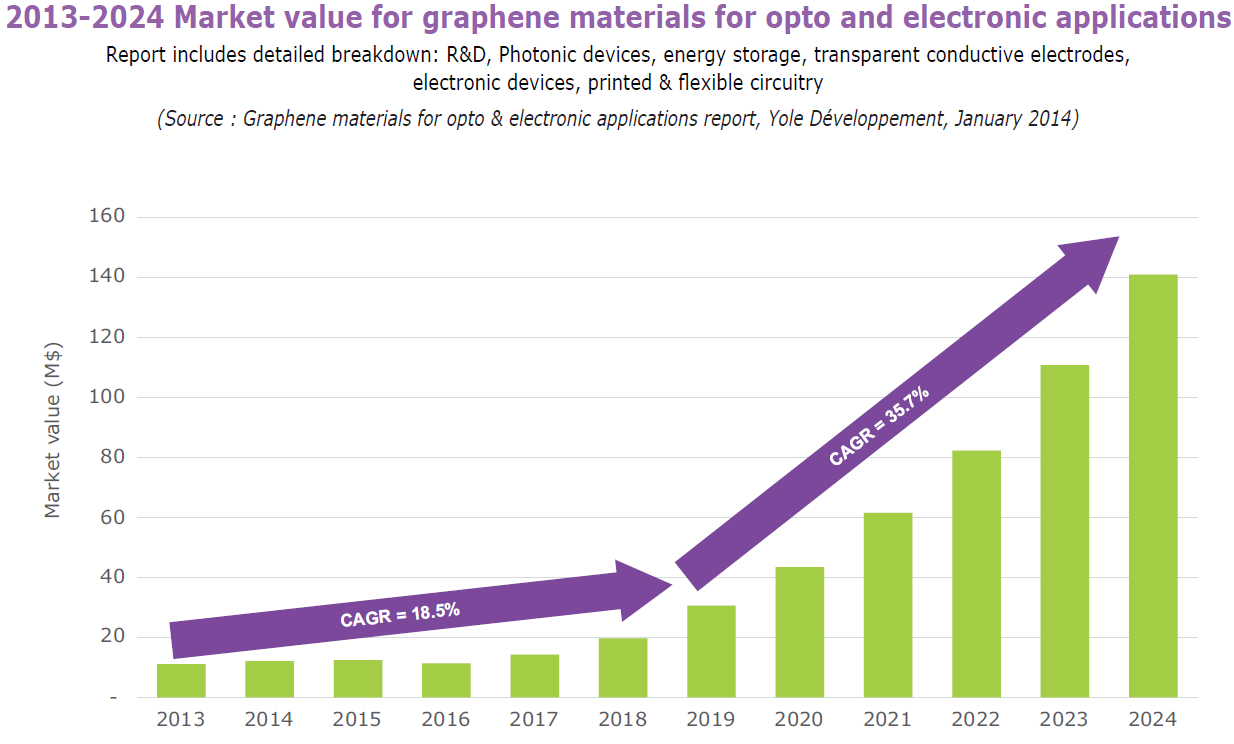

According to the report, the global annual market value for graphene materials in opto and electronic applications will reach $141m (USD) in 2024. This will include CAGR of 18.5% from 2013-2019 and accelerated market growth after 2019, with a 2019-2024 CAGR of 35.7%. Yole Développement forecast that the 2024 graphene material market will be represented mainly by the demand for transparent conductive electrodes and advanced batteries and supercapacitors.

With high interest in graphene technologies, there has been a corresponding increase in demand for graphene equipment. Today, CVD equipment makers are mainly focused on the R&D equipment used to produce high-quality graphene. While leading device manufacturers are already evaluating the graphene technology potential, many of them have internal R&D activities or are developing R&D partnerships with graphene material suppliers. But a widely dispersed graphene supply chain makes it difficult to choose the right supplier.

Many start-up companies are looking to catch graphene market opportunities in their initial stage, since securing graphene IP is crucial to a strong competitive position. Yole Développement has forecasted strong vertical integration trends within the supply chain, due to specific challenges in the production and handling of graphene materials, specifically CVD-made graphene sheets. Graphene nanoplatelet manufacturers are also expected to vertically integrate to gain a higher product value. This will also enable them to better differentiate their products from competitors by offering application-specific materials, such as conductive inks and composite materials for graphene batteries and supercapacitors.

Since many different graphene material types and quality levels exist, a higher level of standardisation is therefore important in graphene technology. This is particularly true for the suppliers of high-quality graphene materials to differentiate better from other suppliers, and for companies with a long-term business strategy. There is also an opportunity for companies developing specialised tools for graphene quality characterisation.

The development and industrial production of new graphene applications will require a reliable supply of graphene with consistently high quality. Graphene materials can currently be produced as tiny flakes (nanoplatelets) or in the form of a large-size sheet on different substrates, such as a metal foil or silicon carbide (SiC). Featuring the high potential for both scalability and high material quality, the catalytic CVD of graphene on metals has the largest potential for mass production of graphene opto and electronic devices. Despite being limited by the dimensions and high costs of SiC wafers, the market potential of high-quality epitaxial graphene on SiC may be successfully applied to produce some high-end electronic applications. The nanoplatelets can be produced by different methods, such as liquid phase epitaxy or reduction of graphene oxide. These can be used to produce conductive inks for printed electronics and additive materials for energy storage devices, such as Li-ion batteries and supercapacitors.

Since it influences the graphene size, quality and costs, as well as the design of the production line for device manufacturing, the choice of the graphene production technique is of crucial importance to a device manufacturer. Today, it is possible to produce large volumes of graphene materials at relatively low costs and also to produce high-quality graphene. The next challenge is to simultaneously meet both of these requirements.