Meeting the challenges of next-gen automotive designs

As cars become more connected via multiple networks including Bluetooth, Wi-Fi and GSM, as well as being more context aware, life on the road is becoming as data dependent as life on the internet. And where there is data, there must be storage. Rolf Schroeder, Swissbit, explains.

The major data centres of the connected car, such as the infotainment system, navigation system, Advanced Driver Assistance Systems (ADAS) and black-box recorder, must provide plentiful storage for personal content, map data and event information such as location and sensor data to aid accident investigations. As more and more video or radar-based driver assistance systems, as well as V2X communication is built into next generation vehicles, reliance on non-volatile storage is set to increase significantly.

High density NAND Flash has emerged as the preferred storage for these applications, and is available for automotive uses in the form of eMMC (embedded Multi-Media Card) chips, CompactFlash, SD or micro-SD cards, or as Solid-State Drives (SSD) such as PATA/SATA or mSATA drives.

Data integrity is a key requirement for automotive memory, but the environment and use cases present major challenges to semiconductor memory. Temperature is a well-known and important factor governing data retention of Flash, even when devices are located in the dashboard or a head unit in the cabin. Although ambient temperatures can be expected to remain within the industrial range of -40°C to 85°C, in-car electronics can be exposed to such harsh temperatures almost continuously. This, and the way the memory is accessed by systems and users, can significantly impair data retention. To enhance performance, automotive Flash devices implement additional special measures.

A better memory

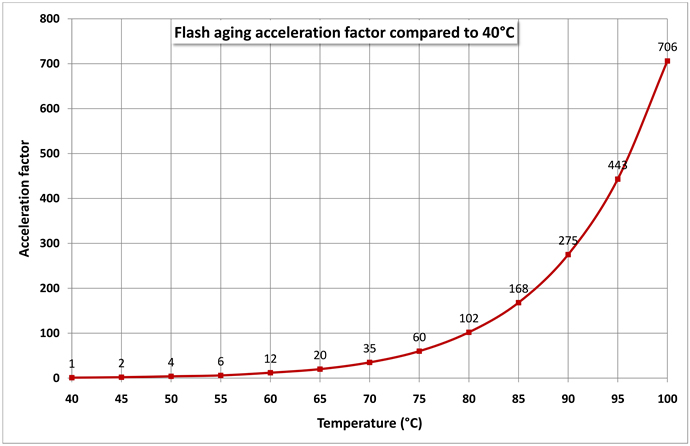

Long term performance is a key concern in the automotive business. As far as storage is concerned, data retention needs to be adequate for the life of the car. Buyers of new vehicles do not expect to experience failures of major systems during the first few years of ownership, and also expect an appreciable residual value when the time comes to sell the vehicle. However, data retention in particular is known to deteriorate over time. For conventional Flash, loss of data retention capability also accelerates with increasing operating temperature. For a 19nm MLC (Multi-Level Cell) NAND the acceleration factors for retention degradation are 6.5 at 55°C and a fatal 168 at 85°C which means that stored data is definitely corrupted after a few months without additional countermeasures.

To counteract temperature related retention loss, some automotive NAND-Flash memories such as Swissbit S-45 and S-450 SD/SDHC cards have introduced automatic read refresh. This enables the memory to guarantee retention even at peak temperature levels.

In addition to long data retention, power fail protection and read disturb resistance are also critical in automotive applications. A navigation system, for example, may need frequent read access to the same page, but this type of usage is known to cause errors in the cells of neighbouring pages. Autonomous data care such as read-disturb management, requiring no intervention from the host system, is effective in eliminating errors in read intensive applications, and so enhances data integrity.

Sensitive electronics can also be vulnerable to noise and instability that characterise the automotive electrical environment. The battery voltage can dip by more than 50% during engine cranking, for example, and systems can also be exposed to surges and spikes as large inductive loads such as fans and pumps are frequently switched on and off to perform various functions in the cabin, engine bay and other areas. Data retention must also be guaranteed in the event of sudden power failure, which may occur if the battery becomes disconnected such as during an accident.

Many industrial Flash devices offer power fail protection, but the defence mechanisms used and their performance varies widely among products from different manufacturers. Today’s best dedicated automotive memories protect against all power-fail conditions through a combination of firmware redundancy, data redundancy and built-in voltage monitoring that blocks access if the supply voltage falls below a defined threshold.

In addition, Swissbit builds extra diagnostic features into its automotive memories, which provide detailed system information that can be used to provide early failure warnings that enable pre-emptive replacement, thereby avoiding unexpected system failures in the field. To ensure optimum reliability, devices are subjected to 100% full temperature test and screening prior to shipping. The company holds relevant automotive quality certifications from factory level to component level, (including AEC-Q100, PPAP and TS16949), and has included every process and function in the scope of its Quality-Management System (QMS).

Conclusion

Meeting the needs of the automotive industry is no longer simply about withstanding high temperatures and noisy electrical conditions. The new automotive specific memories that are emerging move beyond the capabilities of standard industrial devices by introducing advanced data care management, diagnostics and protection features.