SWaP-C – the new way to consider hi-rel connectors

If you drill right down, industry demands can be stripped back to some bare requirements. Smaller size, lighter weight, higher performance (which can mean higher power), lower cost. There is a nice industry acronym that covers this – SwaP-C (size, weight, and Power – Cost) – and it applies perfectly to the selection of high reliability connectors. Robert Webber, Product Specialist, Powell Electronics further discusses.

Interconnect is an interesting subject because connectors are required to play a dual function. They must ensure the transference of electrical signals and sometimes power from one part of the circuit to another. But they also fulfil a mechanical function, physically joining cables and boards. Sometimes they also play a structural role. Ensuring signal integrity and/or power continuity in high-reliability (hi-rel) applications such as defence or space, where extremes of shock, vibration and temperature fluctuation are common, demands very careful consideration of the connectors used.

Let’s take, for example, the CubeSat. CubeSats are a class of miniature satellite based around a cubic form factor where each side measures 10cm (roughly the size of a milk carton), and weigh no more than 2kg. CubeSats have been deployed from the International Space Station or launched as secondary payloads. Currently, several thousand CubeSats have been launched.

Obviously, size and weight are of paramount importance. But since the concept of the CubeSat was to get into space at low cost – with launch costs ranging from $60,000-100,000 and construction starting at just $50,000 – component cost needs to be minimised. If we look at the consumer electronics industry – for example cameras and other portable personal electronic devices – we can find many examples of miniature, lightweight connectors that are very cheap. But for aerospace or space applications such connectors would not be able to withstand the levels of shock and vibration present at launch. A paper by Dave Pignatelli of the California Polytechnic State University, San Luis Obispo, entitled ‘Improving Launch Vibration Environments for CubeSats’ explains that the ‘actual levels (of shock and vibration) experienced by a CubeSat will vary due to a number of factors: launch vehicle/test specification; dispenser and constraint method; isolation implementation’, but ‘internally isolated CubeSat levels ranged from 3.7 Grms to 4.4 Grms’. Other applications and configurations will be much higher. Then there is the issue of temperature change. A satellite flight path may mean that the CubeSat experiences very high or sub-zero temperatures, as it passes from direct sunlight to – borrowing from Pink Floyd – the dark side of the moon.

Clearly another interconnection option is required, and many times, the preferred option is a commercial off-the-shelf (COTS) device, which meet the performance requirements set out by organisations such as NASA or the military, but which may not have been fully qualified to those standards. Such devices are often orders of magnitude cheaper than fully qualified defence parts, but are able to withstand the severe demands of the rugged environments they will be used in.

There is another issue to consider. Connectors that carry full NASA approval may well have been designed 30 to 40 years ago.

If you are operating in the commercial space market, a connector that was designed in the 1980s may not be the best component for your application in terms of size, weight, performance, and cost (SWaP-C). Also, you may need to be able to source your parts for prototype designs from a distributor (such as Powell), which can supply sample quantities from stock. Hi-rel connector makers such as Harwin regularly have conversations with companies in the commercial space sector, which are desperately trying to move away from NASA and ESA standards, wherever they possibly can, exactly for this reason and because older connectors with various ‘hi-rel’ may not be fit for purpose any longer – what was suitable for the Voyager 2 spacecraft to investigate Neptune 40 years ago may well not be suitable for putting up a constellation of 300 low orbit communication satellites to deliver broadband to Africa. It’s a totally different challenge.

So it becomes obvious that we need a modern interconnect solution that has the environmental capabilities (shock, vibration, temperature) of Mil-Spec devices but with the space, weight and cost benefits of a much more recent design. Powell franchise Harwin plc is a long-established supplier of hi-rel interconnect solutions. The company retains all essential production elements in-house at its Portsmouth, UK, facility, so is able to guarantee the highest levels of quality. Some years ago, the company introduced the Gecko 1.25mm pitch connector family. These offered significant space savings over traditional Micro-D style connectors, and, because they are of a rugged plastic design rather than metal, there are considerable weight and cost savings to be achieved.

Gecko-MT range

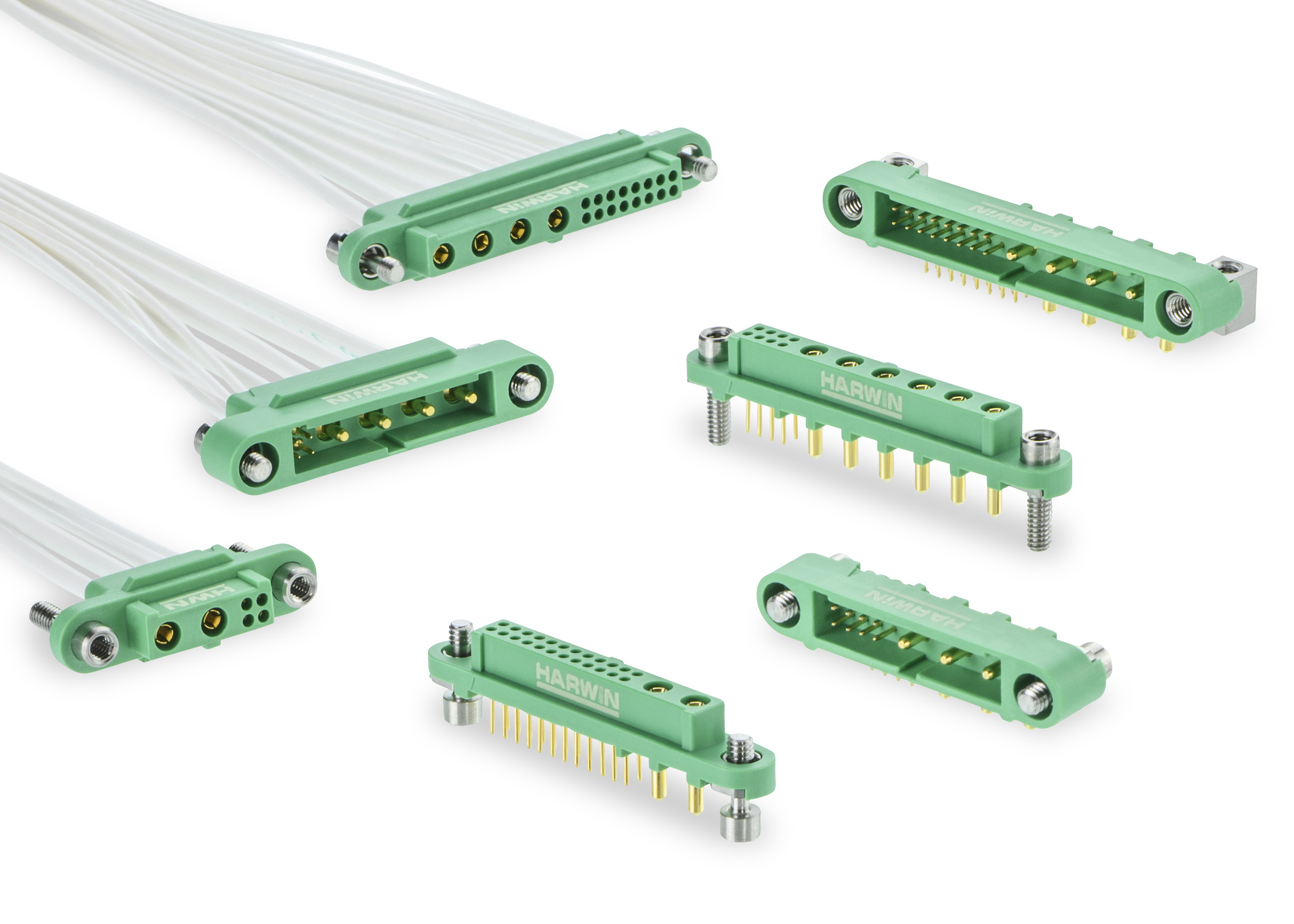

Harwin has continued to extend the scope of the hi-rel Gecko family with the introduction of mixed-layout versions. By complementing the data contacts with two or four power contacts (in power/data configurations of either 1+8+1 or 2+8+2), Gecko-MT connectors achieve even more space and weight reductions in electronic hardware. Recently, Harwin also added six new contact arrangements that feature two to six power contacts and four to 24 signal contacts. These have a non-symmetrical structure, with the power contacts situated at one end and the data contacts at the other. All configurations have respective power and data current ratings of 10A and 2.8A max per contact.

Gecko-MT connectors include female and male cable connectors, plus female vertical and male right-angle PCB connector options. These components are fitted with sturdy, stainless steel screw-lock fixings (in both conventional and reversed formats), to ensure ongoing interconnect integrity in even the most challenging of application environments. They have 20G vibration and 100G shock resilience and their operational temperature range spans from -65°C to 150°C. Low outgassing properties are also exhibited.

By encompassing both data and power in a single compact and lightweight solution, Gecko-MT connectors are highly optimised for avionics, defense, space, and motorsport. Among the key target applications are robotics, unmanned aerial vehicles (UAVs), battery management and satellites. They are available from stock and through Harwin’s distributor, Powell. In addition, cable assemblies manufactured by Harwin, are also available through Powell. Tooling for reliably attaching cables to connectors can be expensive, so the option to buy a complete, tested cable assembly offers users significant cost savings and increased peace of mind.