Using 5S methodology to optimise benchtop cleaning

With component shortages continuing to affect the electronics industry, PCB (printed circuit board) fabricators are looking for ways to improve productivity and reduce waste.

To meet this challenge, some are turning to the tried and tested 5S manufacturing methods for their benchtop electronics cleaning. 5S comes from a lean manufacturing concept of maintaining an orderly workplace which can help manufacturers achieve better cleaning results, boost productivity and gain greater yield with less PCB scrap and waste.

Benchtop cleaning

Benchtop, or manual cleaning, is an important step in the assembly of PCBs. Whether during initial manufacture, for touch-up during post-reflow assembly, or for rework and repair, it is critical that PCBs are clean before moving on to the next step in the manufacturing process.

Anything left on the circuit board that isn’t meant to be there, for example, adhesives, flux residue or fingerprints, may negatively affect the board’s performance. If the cleaning is ineffective, PCBs typically will not make it to the final stages of production or pass final inspection. Contaminated boards simply will not function reliably and must be reworked or rejected altogether.

What is 5S Plus Safety?

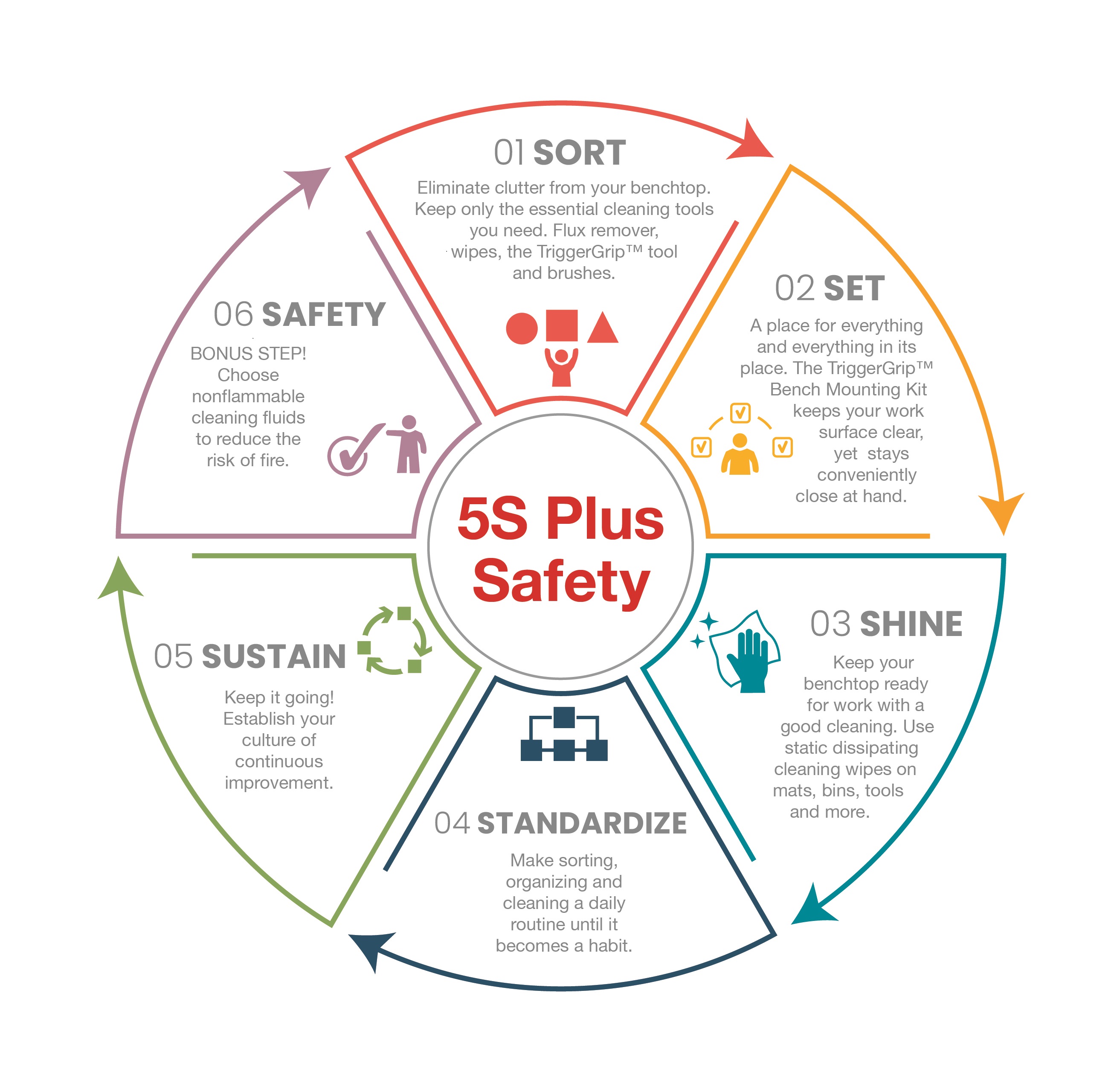

The Toyota Motor Company developed the 5S methodology in the early to mid-20th century. It is a component of the larger Kaizen principle of Lean Manufacturing. 5S focuses on keeping workspaces, clean, neat and organised. The strategy consists of five Japanese words: Seiri, Seiton, Seiso, Seiketsu and Shitsuke. This translates into Sort, Set, Shine, Standardize and Sustain. Many PCB fabricators also add in the extra step of Safety.

Manufacturing experts agree that a company with a systematically organised facility will be more efficient and effective in its production processes. Over time it rewards the business with higher quality, lower costs, increased productivity and a safer, better working environment. Some PCB fabricators are applying the 5S principles in their production facilities in an effort to standardise procedures and improve their benchtop cleaning processes. Here’s how:

Sort

Sort is the first step in the 5S Plus Safety concept. This includes looking at the benchtop and the tools and equipment used. Ask these questions:

- Do we use this equipment?

- When was it last used?

- Does it do the job it was intended for?

- Who uses it?

These questions help determine if the equipment on the workbench is needed, or should even be there. This assists in de-cluttering the workspace and ensures that everything there serves a purpose. For example, only keep essential cleaning tools like flux remover fluids, wipes, brushes and swabs. This allows for quicker visual management, helping save time when PCB cleaning.

One essential tool to have on every PCB cleaning benchtop is a controlled cleaning fluid dispensing system. When used properly, the dispensing system improves PCB cleaning results by targeting dirty areas on the board and getting under low mounted components and inside tight spaces. It also controls the fluid flow to reduce cleaning fluid waste and enhances worker safety by limiting the amount of cleaning fluid fumes released into the air.

Set

Set, or Set-in-Order, focuses on organising equipment, so there is ‘a place for everything and everything in its place’. Position equipment in an ordered manner and in a logical location. This helps establish a systematic way of storing and retrieving items, to maximize accessibility.

Consider how aerosol cleaning fluid cans are placed on the benchtop. For example, moving aerosol cans off the benchtop and placing them in mounted holders on the work bench legs helps keep the benchtop clear, yet still keeps the fluids close to hand. This helps save wasted time searching for the right fluid, reducing labour costs.

Shine

Shine means ensuring the workplace is clean. Maintaining housekeeping is a task often overlooked, but it can impact the effectiveness of PCB cleaning. If the workbench is dirty, it is more difficult to keep the PCB pristine during cleaning. A regular wipe down with a good quality ESD (electrostatic discharge) prestaurated cleaning wipe goes a long way in keeping tools and the benchtop free from dirt, dust and other contaminants that can make their way onto the PCB, all without leaving lint, residue or static charges behind.

Standardise

This step helps to make certain that all the improvements done so far do not go to waste. Standardising procedures and ensuring they are implemented daily will ensure sort, set and shine are not forgotten or overlooked. Use these steps as a standard operating procedure (SOP). When performed regularly, these steps will help improve efficiency and ensure that consistent high-quality PCB cleaning becomes standard.

Sustain

Once the standard procedures for 5S are in place, the steps should be continued and adapted when necessary. Involve the entire workforce in the 5S process including everyone from the PCB cleaning technicians to those in charge of inspection and quality control. Ensuring everyone understands the 5S methodology and why it is important will become a part of the company’s culture and help ensure long-term success.

Safety

Safety is an extra, yet vital step of the 5S process. This means focusing on what can be done to eliminate risks in the workplace.

Look at the cleaning fluids and tools and check the SDS (safety data sheets) carefully to ensure they are safe to use. Advanced PCB cleaning fluids are engineered to have excellent toxicity profiles and high Threshold Limit Values (TLVs), making them safer for exposed workers to use.

Safety is a second reason to consider using a controlled cleaning fluid dispensing system. Because a cleaning fluid dispensing system is a closed aerosol system, technicians do not pour cleaning fluids from open buckets or drums into pump bottles or smaller containers. This reduces the risk of spills and fire hazards and limits worker exposure to any potential fumes.

Make every part count

With components part shortages looking to continue into 2024, there is little room for error when producing and cleaning PCBs. PCB fabricators should regularly review their cleaning processes to make sure every part counts.

When evaluating possible cleaning processes, consider 5S Plus Safety. Optimising cleaning tools and workflow will lead to better quality components, higher productivity, and cost savings. It will also help ensure that every single PCB or component part is long-lasting and does not require rework or scrapping.