Manufacturing companies can lead the race to zero emissions

Over the past few decades, enterprises have increasingly created environmental, social, and governance (ESG) initiatives; benchmarked their carbon emissions using the Greenhouse Gas Protocol; and reported on progress to shareholders.

In the US, nearly all (96%) of the S&P 500 and 81% of Russell 1000 index filed a sustainability report in 2021. This progress is truly inspiring.

Ralf Klädtke, CTO for Transportation Solutions, TE Connectivity further explores.

C-suite leaders and teams want their companies to be good citizens, meet relevant regulations, and evolve with market demands. However, increasingly, sustainability is no longer voluntary: It’s a business imperative.

Manufacturers and suppliers consider sustainability criteria in selecting suppliers and partners, selecting more forward-thinking vendors and partners over those lagging behind. Large financial institutions use ESG principles to make investments, with these assets predicted to surpass $41 trillion in 2022. Activists are disrupting enterprise decision making with demands for greater action. In 2022, there were an unprecedented 627 shareholder proposals related to ESG issues, with another 542 filed by mid-February of this year. And banks are increasingly considering sustainability in how they make lending decisions. Sustainable bonds now represent 11% of the total bond market’s volume, while sustainability-related syndicated loans account for 13% of the global syndicated loans market.

It’s clear that companies that don’t embrace sustainability could find themselves on the outside looking in, with business opportunities and revenues shrinking over time.

As a result, companies are setting more ambitious goals: Increasingly, that means joining the UN’s Race to Zero and driving to achieve zero greenhouse gas emissions across the business.

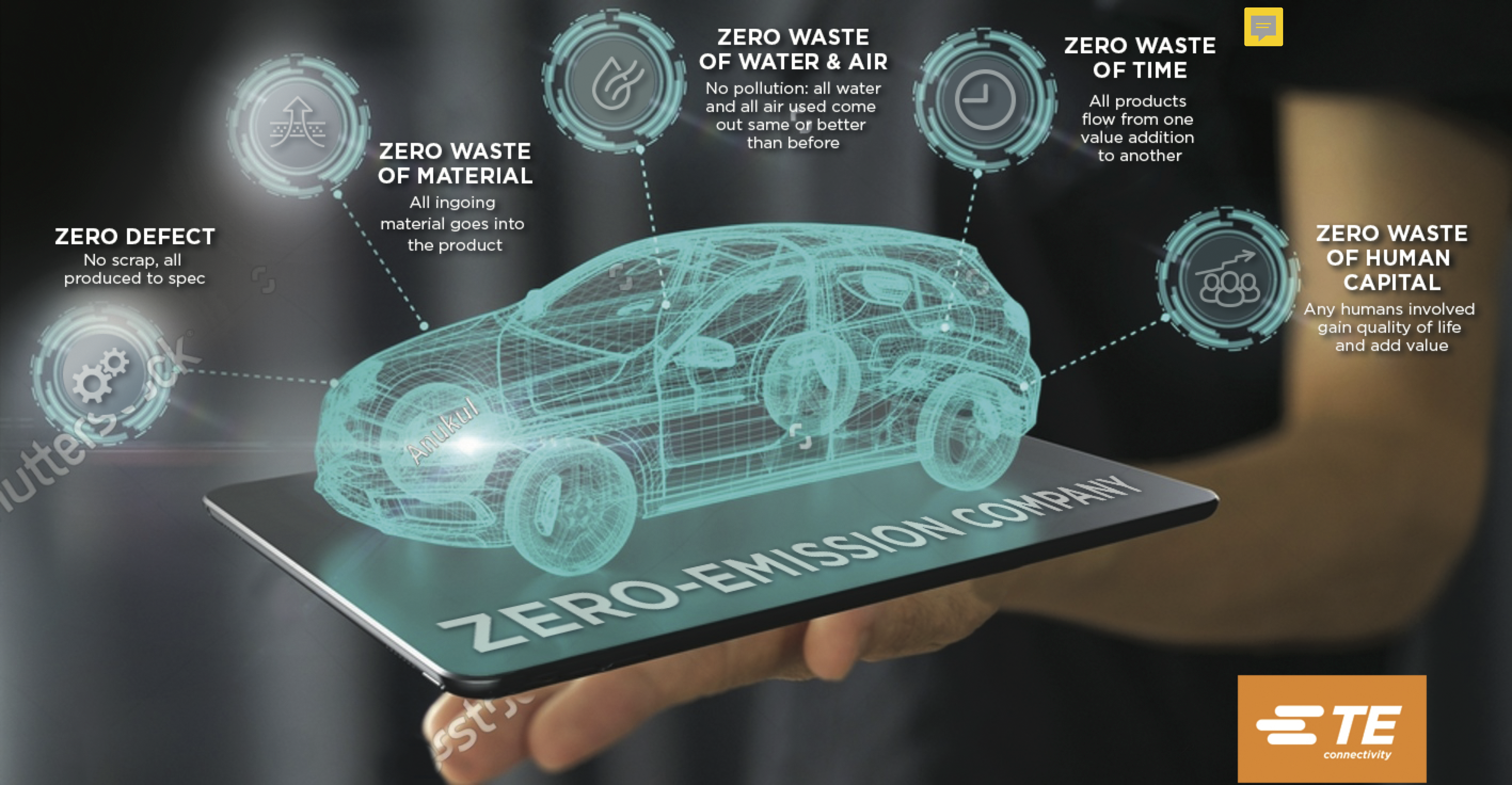

When looking holistically at a ‘ZERO emission company,’ however, we believe organisations could go much further than looking at reducing greenhouse gases only. Companies could and should look at any and all kinds of emission or waste and aspire to:

- ZERO defects: No scrap, all output produced according to specification

- ZERO waste of material: All incoming material goes into the product

- ZERO waste of water and air: No pollution: all water and all air used by the company comes out in the same condition or better than before

- ZERO waste of time: All products flow from one value addition to another

- ZERO waste of human capital: Any humans involved improve their quality of life while adding value to the collective

So, why move beyond just environmental criteria? This five-point framework encourages users to design bold approaches and programs that will future-proof their businesses, conserve resources, and keep the world healthy and safe for generations to come.

What zero carbon means will obviously depend upon a company’s business model, supply chain, production processes, energy consumption, and more. However, one place to start is with product design. Research has found that 80% of a product’s environmental impact is determined during the design phase.

Enterprises can work with their original equipment manufacturers (OEMs) and other partners to reconceive products for a heavily digitised, more sustainable era. This means rethinking how raw materials are sourced and products are formulated, produced, and distributed.

The best minds of business and technology are working on these challenges. For example, we have seen some exciting developments in heavy industry and the automotive sector. They include the electrification of vehicles; miniaturisation and ‘lightweighting’ of components, and adoption of new processes, such as innovative surface plating technologies; to name a few.

Our company is actively participating in this evolution, TE embraced sustainability deeply in 2020 with our One Connected World strategy. Since then, we’ve achieved a 54% reduction in absolute scope 1 and 2 GHG emissions FY2020 to FY2022 and have sourced more than a third (37%) of our energy from zero-emissions sources, including renewable energy. We’re also working to reduce water use by 15% at 30 facilities by 2025 and decrease hazardous waste by the same amount.

As temperatures rise and environmental impacts increase, companies need to make faster progress with sustainability. Manufacturers can lead this charge by committing to achieve holistic zero-emissions goals across their business by 2050 – or ideally, even faster.