5x extended drone range makes humanitarian missions possible

The world’s first commercialised hydrogen fuel cells for drones delivers breakthrough performance with power modules. Electronic Specifier's Caroline Hayes discusses how Doosan Mobility Innovation (DMI) is delivering humanitarian relief to remote locations using drones powered by these innovative energy-dense hydrogen fuel cells.

With two hours of flight time, the drones have transported medical masks and emergency supplies from mainland USA to the Virgin Islands, mainland Korea to Jeju Island and ascended Mt. Hallasan, the tallest mountain in South Korea, to deliver medical AEDs (automated external defibrillators). This technology paves the way for developing mobile robots with extended range and load capacity.

DMI, a subsidiary of the Doosan Group, was established in 2016 to leverage the Doosan Group’s hydrogen fuel cell technology to develop a hydrogen fuel cell power pack for mobile devices and a mobility solution using it. Currently, the DMI hydrogen fuel cell drones are being used for critical applications such as delivering emergency supplies to remote locations, marine search and rescue and monitoring large agricultural areas and vast solar farms.

After securing the reliability, durability, and stability of the hydrogen fuel cell, DMI achieved the world’s first commercialisation and mass production of the 2.6kW hydrogen fuel cell DP30 power pack. The DP30 offers energy density at 400 to 500Wh/ kg, which is four to five times that of a conventional battery. This translates to two hours of flight time for an unmanned aerial vehicle (UAV), more than five times longer than other drones, solving one of the biggest problems in the industrial drone market: short flight time.

Hydrogen fuel cell power packs offer significant advantages for drones, where available payload space and weight are limited, because they only need a stack and hydrogen container to generate electricity. In such fuel cell power packs, hydrogen and oxygen act as fuels for a stack composed of numerous cells made up of a polymer electrolyte membrane and two electrodes. This stack generates ions and electrons through the reaction between hydrogen and oxygen, and because oxygen can be readily obtained from the atmosphere, the fuel cell power pack (pictured below) need only provide its own source of hydrogen.

The DMI hydrogen fuel cell power pack DP30 (pictured above) offers energy density at 400 to 500Wh/kg, which is four to five times that of a conventional battery.

Benefits for fuel cell-powered drones are significant. For infrastructure inspection, a DP30 fuel cell powered drone can monitor a distance of 50km or more per flight, compared to only 10km per flight for a battery-powered drone. In terms of reachable range, a fuel cell-powered drone can cover up to 4,000 kilometres squared from the centre versus only 300 kimometres squared for a standard battery-powered drone. The benefits for operators are significant, as greatly extended flight time maximises utilisation in infrastructure inspection, public safety, logistics, construction/mining, forestry, and agriculture.

Solar panel inspection in Haenam Solasido is achieved with far greater efficiency and speed by DMI drones.

DMI successfully performed a demonstration of these benefits with a solar panel inspection (pictured above) at Korea’s largest solar energy plant in Solasido, Haenam. With a capacity of 98MW, the energy plant was completed this year. Using a DP30 powered drone equipped with a common camera and a thermographic camera, the image of a section of this power plant of about 20MW was obtained by just two automatic grid flights. When performing the same mission using a battery-powered drone, more than six battery replacements are required.

DMI also demonstrated the beneficial impact of extended range with a demonstration of delivering emergency medical supplies to an island at a distance of 70km and are actively developing additional applications, such as delivering COVID masks and emergency supplies to islands near Jeju Island, delivering medical AEDs to Mt. Halla, plus inspecting offshore wind power plants, inspecting domestic power lines, monitoring gas pipelines, monitoring agricultural products, searching for missing persons and investigating and managing rivers.

The company is also focusing on the logistics field, where it can maximise the advantages of long-term flight of hydrogen fuel cell drones.

Two diagrams that cover the hydrogen fuel cell power pack

High-density power design to optimise power pack performance

Developing a hydrogen fuel cell for mobile devices requires overall technological innovation from materials science to full system-level design optimisation.

The key to mobility is miniaturisation, increasing efficiency and lowering system weight. Moreover, high-energy output and durability should be incorporated for a long, stable flight. Therefore it is necessary to reduce the weight of the stack, configure a powertrain with high power density and simplify the design of the overall power pack including peripheral components to fully optimise the system. Core to these design goals is the architecture and implementation of the systems power delivery network (PDN).

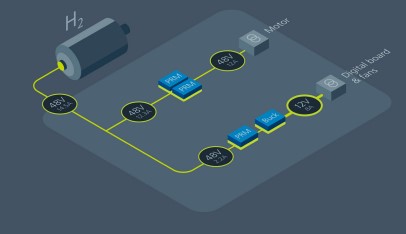

The DP30 power pack has two main powertrains that supply power to the drone’s rotors and the controller for the two stacks. Because of the wide range and variable output voltage of the DP30 power pack, from 40 to 74V, the powertrains were designed to ensure a tightly regulated 48V, 12A output to the rotor motors of the drone, plus a 12V, 8A output to the stack controller board and fans. To achieve high efficiency and high energy density in the PDN, DMI selected Vicor PRM buck-boost regulators and a ZVS buck regulator.

The PRMs support up to 74V open circuit voltage (OCV) of the hydrogen fuel cell stack and perform a stable voltage regulation to 48V. In the drone’s rotor-side PDN, two PRM buck-boost regulators (PRM48AF480T400A00) are configured in parallel to supply the 12A required by the rotors. The PDN for the digital controller board in the stack, uses a lower-power PRM (PRM48AH480T200A00) followed by a 48V-to-12V ZVS buck regulator (PI3546-00- LGIZ).

“The innovation of the DP30 required us to consider how to implement an efficient, energy-dense power delivery network. Vicor has more than 40 years of experience in power conversion topologies, component design, and packaging technology was important to our success. Vicor supplied products of exceptional energy density that provide the best combination of size, power loss, and efficiency. In particular, its solution is supplied as a modular product incorporating individual power elements.

“This simplifies system design, facilitates miniaturisation and lightening, and is much more reliable than using individual discrete components. Vicor has been recognised for its reliability through military-grade products for decades and offers high mean time between failures (MTBF). Its products also feature easy heat dissipation through high efficiency and module-based package,” said Soonsuk Roh, Business Execution Team Manager, DMI.

A circuit diagram of the Vicor PDN solution for the DMI DP30 hydrogen fuel cell power pack

Collaborating and innovating with high performance power modules

Apart from the 2.6kW DP30 power pack currently being produced, DMI plans to diversify product lines by power capacity. The company is expected to develop products with various capacities, ranging from the 1.5kW hydrogen fuel cell power pack that is scheduled to be released next year to a 10kW one, and to launch corresponding drones suitable for each power pack.

The Vicor modular approach to power enables scalability to support such diverse product lines. This also allows DMI to focus on solving other engineering problems, such as stack structure changes, powertrain and peripheral components and heat dissipation methods, all of which arise from the expansion of power capacity. With Vicor, DMI is better able to pursue its main objectives: to increase durability and stability as well as achieve the miniaturisation and lightening of fuel cells with high energy density.

In addition to the recent work in hydrogen fuel cell power packs for drones, DMI has formed an Urban Air Mobility (UAM) consortium with Hyundai Motor Company, Hanwha Systems, Korean Air, and SK Telecom and is pushing to develop drone taxis. DMI is saving lives and expanding to new frontiers with its world changing technology.

About Doosan Mobility Innovation

Doosan Mobility Innovation (DMI) is a subsidiary of Doosan Group, one of the leading global companies in the hydrogen fuel cell market. It was established in 2016 to develop hydrogen fuel cells for mobile devices. Doosan Group has built a complete technology, supply, and production system ranging from materials to systems in the markets of the phosphoric acid fuel cell (PAFC) for 50 years and solid polymer electrolyte membrane fuel cell (PEMFC) for 30 years, supplying fuel cells for automobiles, households, power generation, and buildings.

Meanwhile, DMI has focused on the development of hydrogen fuel cells for mobile devices based on Doosan’s proven hydrogen fuel cell technology and various experiences in the stationary applications sector. Moreover, it contributes to the development of the unmanned aerial vehicle (UAV) industry, such as drones and drone taxis.