Thermal management for 5G

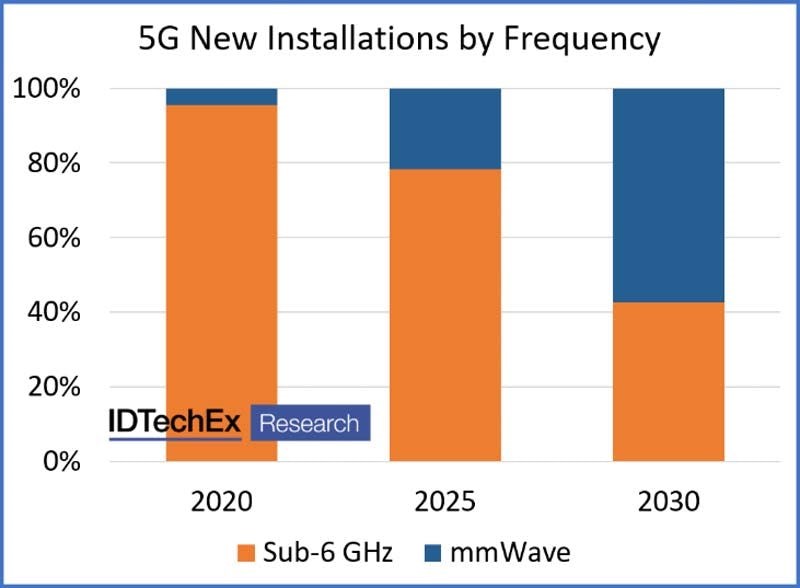

The 5G market is expanding rapidly, with the first installations already being demonstrated. The increasing deployment of 5G will generate innovation and growth opportunities in thermal management. The shift to higher frequencies, and the accompanied higher signal loss, necessitates the densification of network installations, hence, utilising many more small-sized (pico or femto) stations. This acts to multiply the potential market for 5G infrastructure.

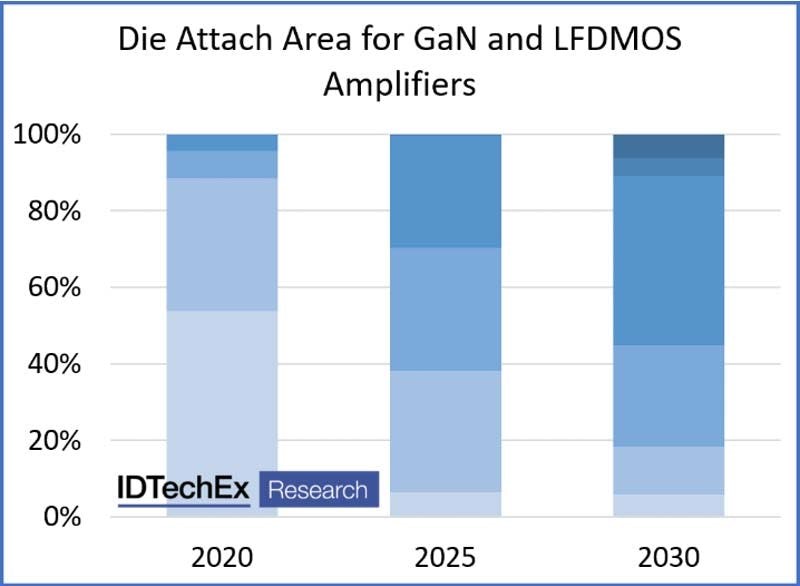

Additionally, the growth of sub-6 GHz installations opens the door for new power amplifier semiconductor technologies such as GaN. This is accompanied with a transition away from incumbent die attach materials like AuSn towards emerging alternatives, for example, pressure-less silver sintering.

As new semiconductor technologies are implemented, the choice of die attach evolves too. In this report the use of AuSi, AuSn, Ag pressure sintering, Ag pressure-less sintering, Cu pressure sintering and Cu pressure-less sintering are considered. Source: IDTechEx Research, 'Thermal Management for 5G'.

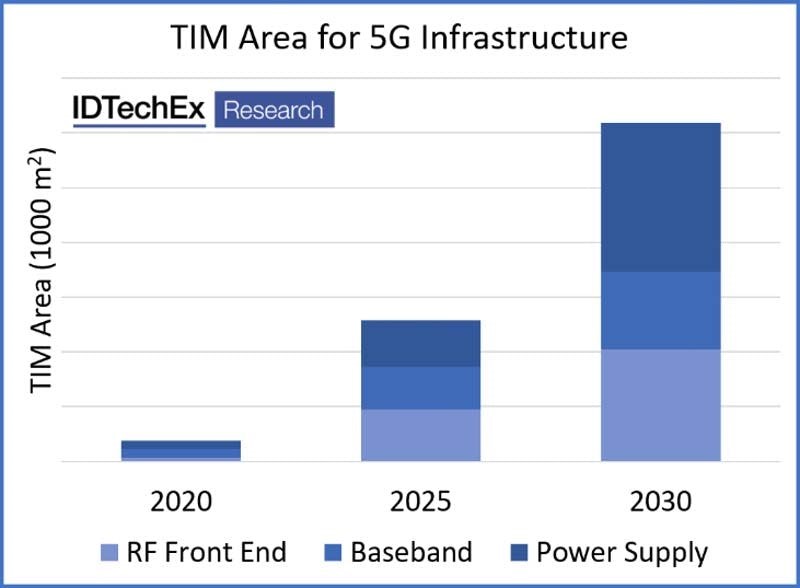

The rise of massive MIMO increases the number of RF chains per installation, beamforming capabilities and the number of antenna elements used in networks. This results in an increase in the materials required for the antenna PCB, power amplifiers, beamforming components and many more. Massive MIMO also drives data transfer rates and channels higher leading to a greater requirement on baseband processing units, power consumption and hence greater market opportunities for thermal interface materials.

With increasing 5G installations the Thermal Interface Material (TIM) requirement increases drastically to match. TIM is required in the antenna RF front end but also for the baseband processing and the power supply, leading to a large potential market. Source: IDTechEx Research, 'Thermal Management for 5G'.

With the future rise of mmWave, even more drastic changes will be seen in the 5G market and opportunities for thermal management. To increase antenna gain, the number of antenna elements also increases, but due to the smaller wavelength, the antenna itself can be smaller. This leads to a densification of components with a drastic increase in the number of power amplifiers and beamforming components that need to be integrated. Considering teardowns of current early devices, this will likely be done by distributing components behind the antenna in a dense lattice-like structure, resulting in power dissipation challenges and hence a larger market for thermal management materials.

As the 5G deployment goes on, a greater shift is seen towards mmWave installations, presenting further new opportunities for thermal management materials. Source: IDTechEx Research, 'Thermal Management for 5G'.

As the component number and density increase in a hybrid beamforming arrangement, we see many more beamforming components but also the potential to reduce the use of discrete power amplifiers, integrating them into the beamforming component. This high level of integration could then also see the market shift back towards silicon-based components in the long term.

Many of the initial 5G mobile phones that were tested by the public (especially the mmWave compatible ones) would overheat whilst utilising 5G's high download speeds and would drop back to using 4G in order to cool down. This is a very temporary solution, consumers going forward will want these extreme download speeds to reliably perform for much longer timescales. There are several strategies used by manufacturers to help keep heat to a minimum in smartphones, with the incorporation of 5G we are seeing a greater increase in devices utilising technologies such as vapour chambers and even graphene heat spreaders. Much like in previous generations of phones, how thermal interface materials are used and in what quantity is an important factor and a very large market in itself.

In the Report 'Thermal Management for 5G', IDTechEx carried out an extensive analysis of the 5G infrastructure market, observing the trends and combining this with evaluations of current installations and their construction. The report starts with 5G deployment forecasts and segments through frequency, station size and MIMO size in order to cover each use case in-depth. For each of these considerations, it is then broken down by the number of antenna elements, power amplifiers and beamforming components required. From here the trends in semiconductor technology are assessed depending on the antenna power and gain required.

How the die attach market is evolving and how this will change with semiconductor technology is considered to provide a die attach market forecast. The baseband processing and power supply requirements are also considered between different station sizes and frequencies. Finally, the total areas of the previously mentioned components are used to calculate the requirement for thermal interface materials in 5G networks. For each of the mentioned quantities, the report retains the segmentation of previous forecasts, this allows for an extremely granular technological and market overview. Teardowns of previous and new 5G smartphones are used to give realistic estimates of thermal interface material usage and forecast through to 2030.

What this report provides:

Technology assessments:

- 5G installation sizes (macro, micro, pico & femto)

- 5G deployment frequencies (sub-6 GHz & mmWave)

- MIMO and massive MIMO installations

- How the number of antenna elements and board size increases

- Analog vs hybrid vs digital beamforming architectures

- Sub-6 GHz and mmWave installation teardowns and assessments

- Integrated vs discrete power amplifier technologies

- Beamforming and amplifier components in the 5G RF chain

- Semiconductor technologies for 5G networks

- Die attach materials for RF power amplifiers: AuSi, AuSn, pressured and pressure-less metal sintering

- Power demands for 5G networks including the antenna and baseband processing units

- Thermal interface materials and applications: tapes, adhesives, greases, gels, pads, phase change materials, graphite, solders, boron nitride, graphene, CNTs and more

- Thermal interface materials for antenna, baseband processing and power supplies

- Thermal management approaches in smartphones

- Thermal interface materials for smartphones with teardown analysis

Market assessments:

- Key 5G players and patent landscape

- The RF GaN industry and its suppliers

- Suppliers of active antenna units

- Sintering materials, their suppliers and assembly companies

- Thermal interface materials, applications, types and suppliers

Forecast lines (2020-2030):

- 5G installations by sub-6 GHz or mmWave frequency

- 5G installations by station size (macro, micro, pico & femto)

- 5G installations by MIMO size (2X2, 4X4, etc.)

- The number of antenna elements by MIMO size

- Area and mass of PCB materials required for antenna by MIMO size

- The number of power amplifier and beamforming components by MIMO size

- GaN die area for amplifier components

- Amplifier semiconductor area by semiconductor choice

- Die attach area and mass by station size

- Die attach mass for GaN and LDMOS amplifiers by attach technology

- Total market value for sintering materials in 5G by sintering technology

- Thermal interface material area by station size and station frequency

- Thermal interface material area for baseband processing units by station size

- Power consumption for 5G by station size and by baseband processing vs antenna

- Thermal interface material area for power supplies by station size

- Total thermal interface material area for 5G stations by size and by baseband processing vs antenna vs power supply

- Thermal interface materials for smartphones