MIT develops 3D-printed mass spectrometer components

Researchers at the Massachusetts Institute of Technology (MIT) have developed miniaturised, 3D-printed components for mass spectrometers.

This advancement brings us closer to portable mass spectrometers that can efficiently identify chemicals in remote settings, overcoming the limitations of conventional, bulky, and expensive devices.

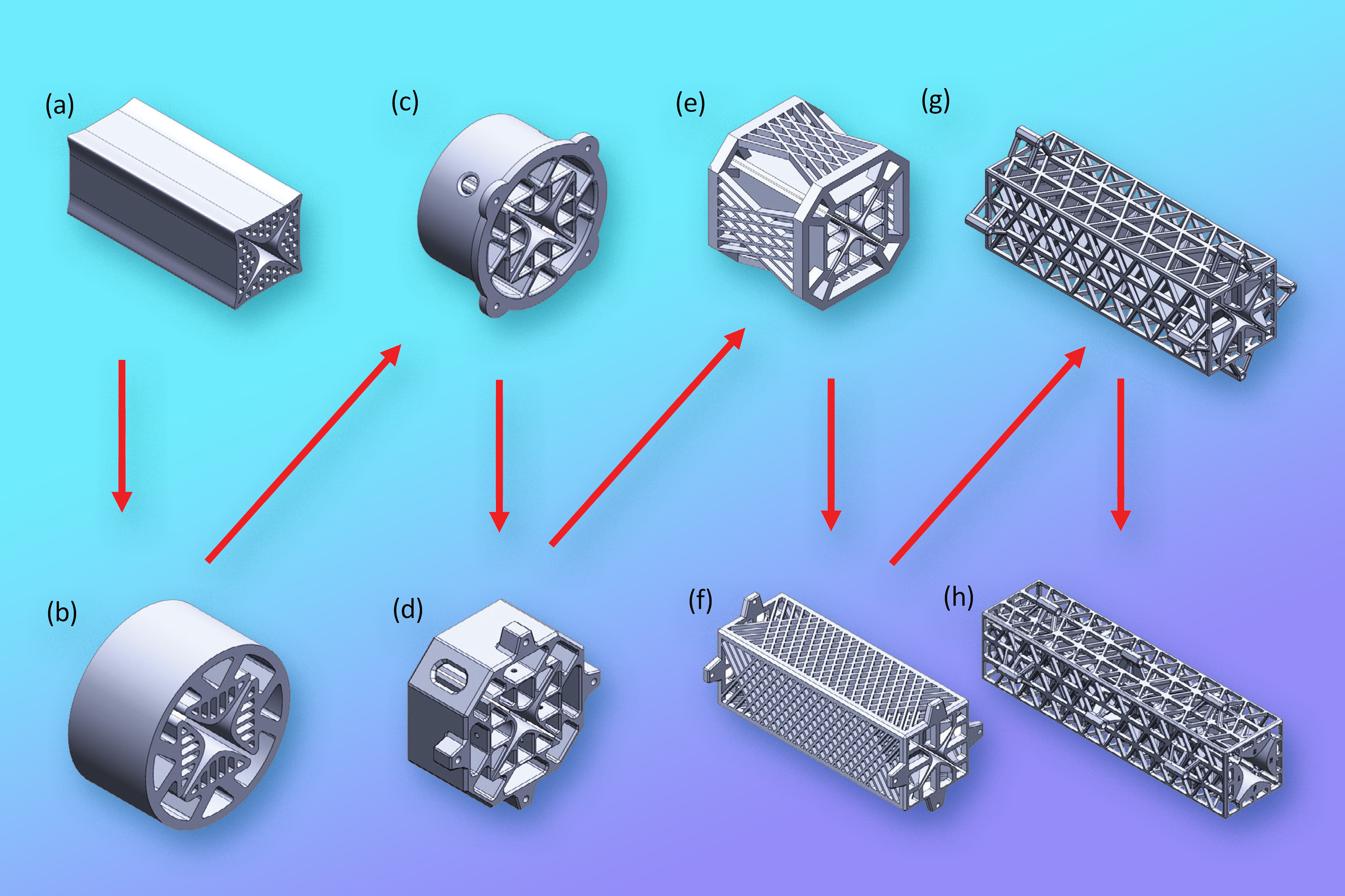

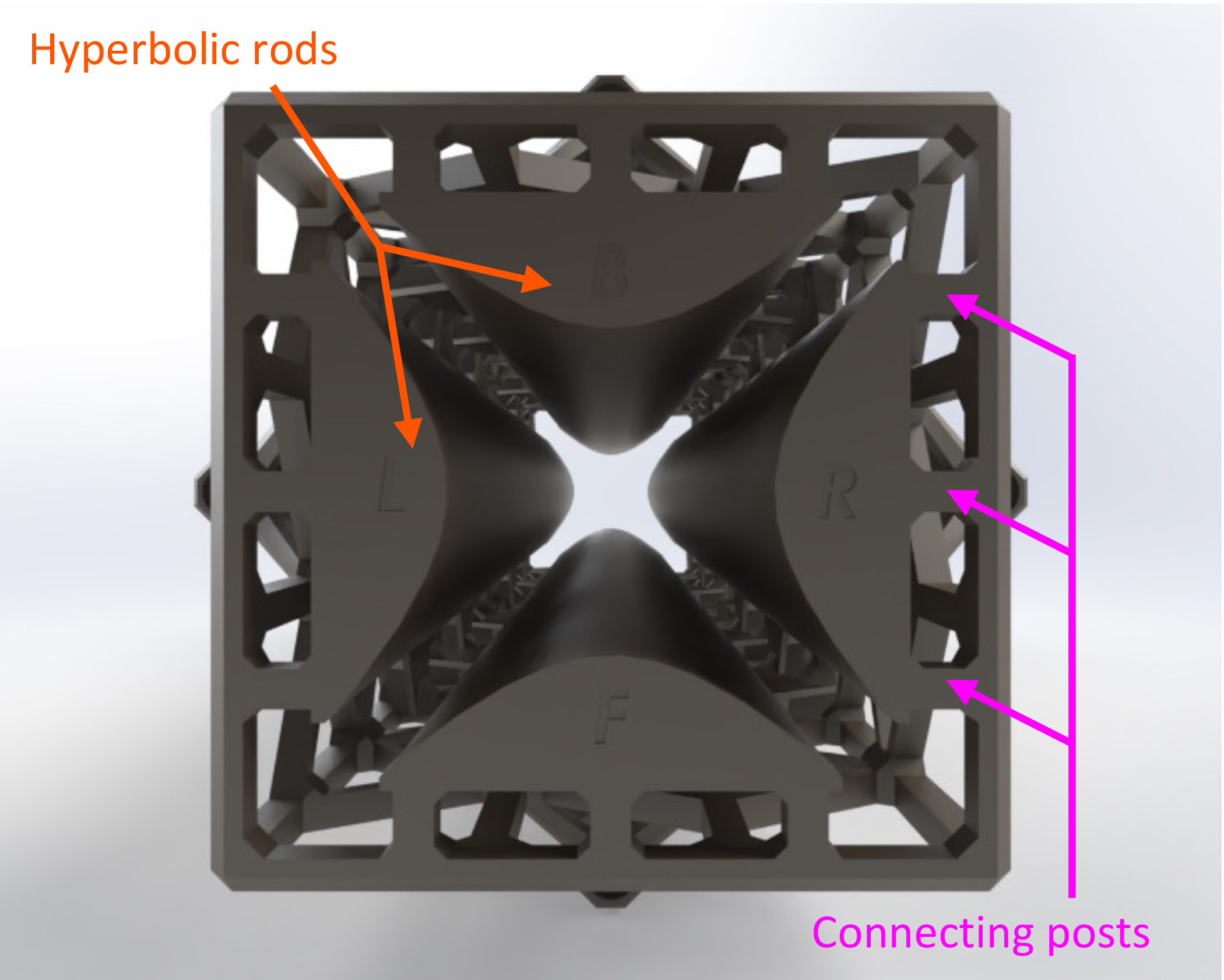

The mass filter, the heart of a mass spectrometer, has traditionally been cumbersome and costly. Using additive manufacturing, the MIT team, led by Luis Fernando Velásquez-García, has produced a lighter, cheaper mass filter known as a quadrupole. Unlike conventional filters, this 3D-printed quadrupole can be fabricated quickly and inexpensively, maintaining precision comparable to commercial-grade mass filters that are often exorbitantly priced and time-consuming to produce.

Constructed from a durable, heat-resistant glass-ceramic resin, the 3D-printed filter is built in a single step, thus eliminating assembly-related defects. This innovation is part of Velásquez-García's two-decade quest to create a portable mass spectrometer. "We are not the first ones to try to do this. But we are the first ones who succeeded at doing this," says Velásquez-García, highlighting the unique performance of their miniaturised quadrupole compared to other existing models.

With this development, scientists could potentially carry portable mass spectrometers to remote locations, like rainforests, for quick analysis of pollutants, bypassing the need for sample transportation. Additionally, the lightweight nature of the device makes it ideal for space missions, enabling chemical monitoring in Earth's atmosphere or on distant planets.

The quadrupole works by sorting charged particles based on their mass-to-charge ratio using electric or magnetic fields. The MIT team has innovatively designed the quadrupole with hyperbolic rods, an ideal shape for mass filtering but challenging to produce with traditional methods. The 3D-printed quadrupole is encased in a triangular lattice structure for enhanced durability and accurate rod positioning.

A key step in the manufacturing process involves electroless plating, where the rods are coated with a thin metal film for electrical conductivity, without compromising the integrity of the device.

Initial testing of these 3D-printed quadrupoles in commercial systems has demonstrated higher resolution capabilities than other miniature filters. The research team aims to further improve the quadrupole’s performance by exploring longer filters for more precise measurements and investigating different ceramic materials for better heat transfer.

"Our vision is to make a mass spectrometer where all the key components can be 3D printed, contributing to a device with much less weight and cost without sacrificing performance. There is still a lot of work to do, but this is a great start," adds Velásquez-Garcia.

This research, funded by Empiriko Corporation and detailed in a paper published in Advanced Science, is a collaborative effort including lead author Colin Eckhoff, Nicholas Lubinsky, and others from Ardara Technologies. It represents a significant leap forward in making chemical analysis more accessible, efficient, and versatile, with vast potential in environmental research, space exploration, and beyond.