3D printing technique could aid the study of rocks

A 3D printing technique being developed at Stanford could one day allow scientists to study rocks from afar, without needing to have actual samples in hand. By combining two techniques—remote 3D imaging and 3D printing—scientists could create physical models of digitally scanned rocks that are either too delicate to handle or too difficult to obtain in person, such as rocks from the moon or Mars.

"You could use 3D printed digital rock models to help screen and select the most scientifically interesting samples to return to Earth for research," said Tiziana Vanorio, an assistant professor of geophysics at Stanford's School of Earth, Energy & Environmental Sciences. "Our study provides a first step in that direction."

For now, though, 3D printing could help scientists better understand how changes to a rock's microscopic structure affects its large-scale, or "bulk," properties, such as porosity and permeability.

These characteristics can reveal intimate details about the rocks, such as the physical processes that formed them, or how fluids such as oil or water move through them, which could inform more efficient extraction techniques.

"The advent of modern 3D printing provides an unprecedented opportunity to link the micro- and macro-scales by combining the strengths of both digital and laboratory experiments," Vanorio said. "Three-D printing allows us to digitally manipulate changes at the pore scale and then print the rock at the scale that is suitable for laboratory tests."

Scientists have used 3D printing on rocks before, but mostly as a means of enlarging the tiny structural details in rock interiors to make them easier to visualise.

"No one else has done what we did, which is digitally modify parts of a natural rock microstructure and then physically measure in a laboratory how those changes affect fluid flow in the rock," said Dulcie Head, a Stanford doctoral candidate in Vanorio's lab.

Vanorio said she got the idea to print rocks in three dimensions after purchasing a pair of customised ballerina shoes a few years ago.

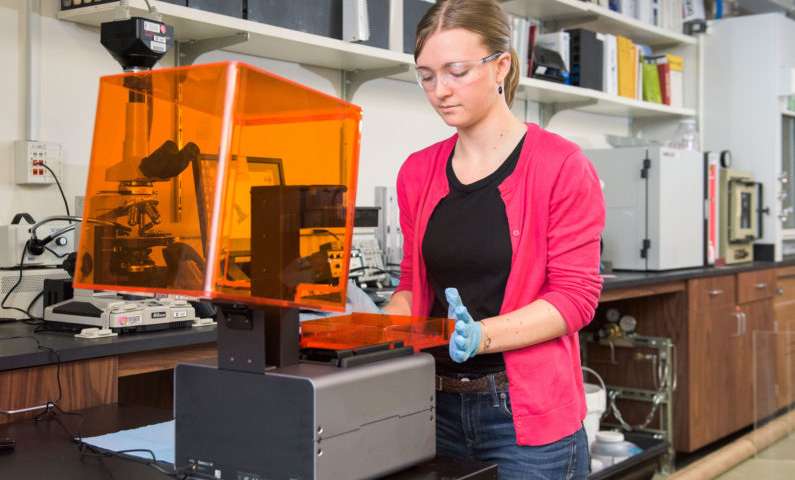

Dulcie Head loads a tray of resin into the 3D printer that she and Professor Tiziana Vanorio used to create physical models of digitally scanned rock samples. Credit: L.A. Cicero

"The company used a digital scanner to determine the exact size and shape of your feet and then 3D printed shoes that fit you like a glove," Vanorio said. "Geophysicists already digitally scan rocks, so I thought to myself 'Why not print them, too?'"

In a new study, to be published in an upcoming issue of the journal Geophysical Research Letters, Head and Vanorio tested whether current 3D printers were up to the task of re-creating the microscopic channels and hollows in a small carbonate rock sample that had been digitally imaged using a CAT scanner.

The pair tested two different 3D printers: a high-end commercial model costing a few thousand dollars and an industrial model that cost about ten times more.

Both printers layered light-sensitive resin that is then hardened using ultraviolet light, but the industrial model had a higher printer resolution and used a wax-assisted technology to enhance the rendering of small pore spaces.

The Stanford scientists demonstrated that it was possible to manipulate the digital model of the rock sample and then print the altered version in 3D. The research, which was selected as an Editor's Choice by the journal Science, could for the first time allow scientists to directly link changes in a rock's microstructure to its bulk properties such as porosity and permeability.

Vanorio and Head are optimistic that as 3D printing technology improves, scientists will be able to recreate finer details of rock structures and even be able to mix different materials together to better replicate the diverse minerals that make up rocks.