How do you solve a problem like systems?

Everything you see in modern electronics is a system and these are often part of a system of systems. However, as technology has advanced these systems have become increasingly complex – leading to integration issues between different systems. Electronic Specifier Editor Joe Bush talks to David Wiens, Xpedition Product Manager, Board Systems Division, Mentor Graphics, about these problems and how the company’s Xpedition offering can provide a solution.

In a world of rapidly advancing technology, applications that were once largely singular mechanical entities (such as machines and automobiles), have fast developed into a complex web of components, systems and sub-systems that all play their part in the creation of the final application – creating a ‘system of systems’.

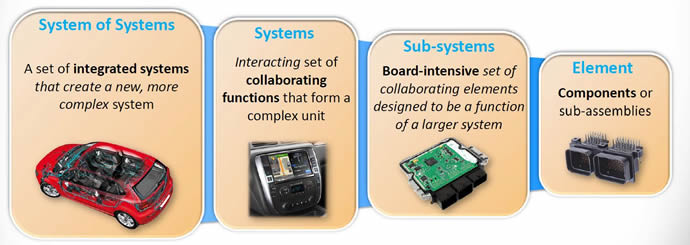

Fundamentally a system is a hierarchy of sub-components that build a greater product. If you look at an automotive example (below), you start off small with a component element like a connector or an off the shelf sub-assembly. That part gets taken and put onto a sub-system like a board, which is designed to perform a function in the end system. That sub-system then gets integrated with a set of collaboration functions to provide an end function like a navigation system, which then gets plugged into a car – a system of systems.

Added complexity

The level of complex connectivity and integration that these systems require to operate at an optimal level has created a multitude of challenges across many applications in terms of managing design complexity, enabling multi-team collaboration, optimising product performance and reliability and leveraging IP across an organisation.

“The management of electronics connectivity is immensely complex and a key challenge for systems architects today, yet this problem hasn’t been adequately addressed previously,” stated Laurie Balch, Chief Analyst, Mentor Graphics.

Wiens added: “People have been designing systems since the birth of electronics. However, the problem today is that the complexity has become so great that the ad-hoc processes that existed to integrate those systems have broken down, for example between electronics and mechanical, hardware and software and hardware and cabling.”

The process of how all these elements are integrated together has been neglected as, to a large extent, it wasn’t really critical – that is until now. Wiens continued: “We’ve reached a level where system complexity is so great that managing collaboration across disciplines is near impossible. And when you haven’t got that collaboration you are restricting your end product as you can’t manage trade-offs. If you specify too early in the design cycle how hardware and software will be segregated, and you don’t allow any changes after that point, then you fundamentally restrict what your end product is going to do. There will be trade-offs in performance, weight, cost, size etc. All of these things become restricted because there is limited collaboration between the different teams which would have enabled them to work these things out.”

The aim of Mentor Graphics is to enable efficient integration across disciplines, and automation of steps that, when done manually, will introduce a lot of time and errors into the process. The company has historically worked within specific domains and has disciplines to improve and optimise IC, package and PCB design for example. However, the company has also realised that it needs to help optimise integration across disciplines, and it’s this area that presents the greatest challenges.

“People are getting quite excited about designing at this level and optimising this process, front to back, and that’s where Mentor has spent a lot of time developing systems that integrate these things together,” added Wiens.

Critical systems design stages

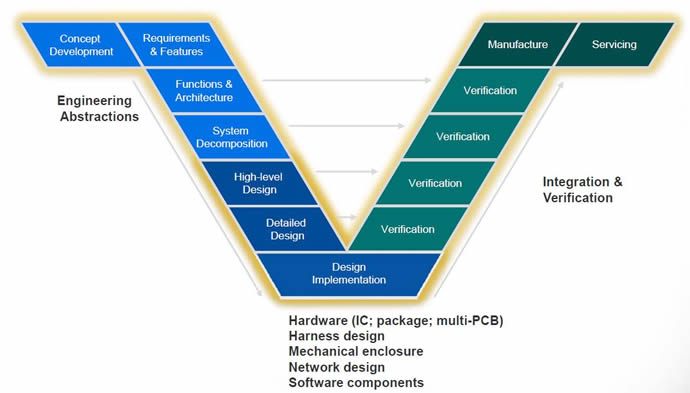

The process of system design involves a journey from concept right through to manufacture and servicing. The question for designers is how best to get there? Therefore, designers build-in some requirements and define some level of architecture and then start to break down the system into fundamental parts – in terms of PCB, packaging, hardware, harness design, mechanicals, network design and software components. Those parts are integrated back together, and are then verified prior to completion of the finished product. And it’s this continuum that Mentor is trying to enable.

Wiens added: “Mentor’s vision is to service this system of systems design spectrum from concept to manufacture. There are lots of tools that we are leveraging to create that vision and we are better equipped than our competitors in that space as we have all manner of domain tools outside of the traditional PCB design space.”

Design challenges

Drilling down into the system of systems spectrum, there are big problems to solve at the implementation stage. The problem at this level is that the processes involved i.e. cabling/harness, mechanical, networking, software and hardware, are black box processes. They are processes with teams that have their own language and their own location, and are disparate entities that aren’t designed to function efficiently together.

Designing systems that contain multiple interconnected boards (connectors and/or cables) has traditionally been done with separate uncoupled board and cabling projects held together by desktop office tools such as spreadsheets for intra-board connectivity, text files for system element parameters and drawing applications to show block level system structure and hierarchy. The result is poor collaboration between cross-domain design teams, costly intra-system connectivity errors, extensive time consuming manual validation steps, and restrictive system change rules that prohibit system design optimisation. This lack of holistic multi-board system design further impacts the ability to design networks of interconnect electronic systems (system of systems) that are commonly seen in automotive, space/satellites, industrial automation and data centre infrastructure.

Commenting on this scenario Wiens continued: “Concepts can be understood but information is not being passed efficiently between one step of the design process and another. People will ultimately try to add their own automation where possible but you’re fundamentally working with weak foundations to build that integration.”

These organisational boundaries, Mentor claim, impede success and one of the company’s customers has stated that: “Establishing effective architectures across all domains has become virtually impossible. Our machines have crossed a threshold of complexity where we are no longer able to respond by adding more people.”

So overall with this sort of system you have inefficient collaboration, restricted optimisation, limited re-use within and across domains, mismatched integrations (which is a huge issue and can occur in a number of combinations that will ultimately require a redesign). And so, to avoid those mismatched integrations, there is an awful lot of manual validation cycles performed – which are time consuming. These all result in the management nightmares of reduced system performance, extended design time, reduced quality and increased product cost.

Multi-board system design and challenges

Multi-board systems design is where the Mentor Graphics system of systems journey is today. A single board system is almost unheard of these days. Even your average smartphone has got around three boards. What that means is designers have to figure out different ways to connect them together. With a system like this the goal is to design connectivity from the conceptual level down to PCB layout in a single design flow in the shortest time, with fewer re-spins and improved consistency of drawings, but this also presents some challenges.

Wiens explained: “In multi-board design the problems are that disconnected and non-intelligent tools are used to describe and define system schematics, and when you have designs that have tens of thousands of connections, which is not unusual in the modern world, then you can only imagine the potential problems.

“However, the reality is that this is how people work today. So they have to manually define the schematic, check it to make sure it’s correct and then make any necessary changes, for example swapping over a couple of pins out of tens of thousands. You wouldn’t want to be the person to go through an Excel file to do that, but that is the current reality. It boils down to the same problem that was discussed earlier – that being integration across multiple domains.”

This rather inefficient reality is perpetuated by the complexity of the systems we have today. In years gone by, people were able to work in this way because their systems were simple. However, according to Wiens a breaking point is fast approaching where integration between domains is becoming increasingly vital.

The natural chasm between systems architects working in Excel and Visio for example, and the hardware designers creates a number of problems. Firstly it results in data having to be re-entered multiple times during the design process because system architects and hardware designers are working on different platforms. Other problems include costly manual validation and correction of connectivity errors, restrictive system change rules and no architectural budgeting and trade-off analysis.

Xpedition Multi-Board Systems Solution

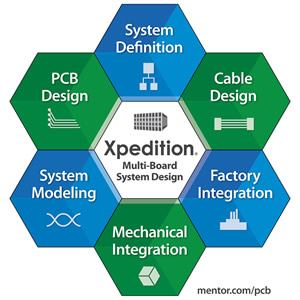

The solution Mentor Graphics has developed helps to enable team-driven systems design. The new Xpedition multi-board systems design solution enables seamless concurrent multi-discipline team collaboration to efficiently manage increasing system complexity. The Xpedition flow maximises team efficiency by eliminating redundant effort during the design process, and optimises product performance and reliability with a data management infrastructure. This ensures data integrity and leverages reusable IP across all boards, connectors and cables in the system.

The new Xpedition multi-board systems design flow improves design team productivity and reduces development cost by replacing inefficient paper and manual processes with an automated, fully integrated, collaborative workflow. The automated synchronisation between all levels of abstraction and automated connector management will help design teams achieve time-to-market targets. Signal tracing, functional and signal integrity simulation, and design partitioning and re-partitioning while maintaining connectivity content ensures ‘correct by construction’ system design. The Xpedition flow is a fully parallel collaborative design environment where global teams can work in real time, providing companies with the flexibility and technologies to develop innovative and competitive products.

Xpedition Multi-Board Systems Solution - Key Features

- Single desktop engineering environment for architecting, partitioning, authoring and documenting the logical definition of electronic multi-board systems.

- Managed synchronisation of multi-board systems board designs enabling interface reduction, removal of manual data handling, data duplication and ECO transfer errors.

- Integrated connector management that eliminates connectivity mating errors, from the initial design conception through the entire design cycle, including PCB projects and purchased components by design.

- Integrated multi-board system level connectivity verification.

- Built-in change management through controlled synchronisation between multi-board system boards and cables.

- Integrated management of logical cable connectivity into physical representations, including bi-directional collaboration with 3D MCAD.

- Collaborative concurrent design environment for engineers and implementation teams assigned to partitioned functions and related boards, while automatically managing data integrity and connectivity.

- Integrated library browsing for intuitive system level part research, selection and management.

- Leverage existing architecture IP by importing and embedding Visio data into the system design and by attaching characteristics to system elements.

- System data management enables multi-discipline collaboration and facilitates reuse of boards, connectors and cables across the team.